High-Quality Meat And Bone Meal Processing Equipment

High-Quality Meat And Bone Meal Processing Equipment

Introduction Of Sunrise Meat And Bone Meal Processing Equipment

Meat and bone meal processing equipment is used to produce meat and bone meal from raw materials such as cattle, sheep, swine, poultry, and fish. The output of the machine is a fine powder of meat and bone.

The meat and bone meal is a by-product obtained after the slaughter of livestock. It is rich in protein, phosphorus, and calcium. Therefore, it can be used as food additives or feed additives to improve the nutritional value of food or feed.

Processing equipment for meat and bone meal can be divided into three categories: Storage and crushing equipment, cooking and drying equipment, oil pressing equipment, and finished product packaging equipment.

1. Storage And Crushing Equipment

The raw materials transported by the raw material truck are temporarily stored in the raw material warehouse, and the raw materials enter the crusher for crushing, and the raw materials are broken into 4-5cm meat pieces, which shortens the time for cooking and saves energy and time.

2. Cooking And Drying Equipment

Put the material into the cooking machine like Sunrise Batch Cooker for high-temperature and high-pressure cooking.

3. Oil Pressing Equipment

The dried material enters the oil press machine through the screw conveyor, and the oil in the material is squeezed out. After being separated by the centrifuge, the oil enters the finished oil tank for storage.

4. Finished Product Packaging Equipment

The powder from the extruder is finely ground and then packaged.

Main Features Of Meat And Bone Meal Processing Equipment

The Meat and Bone Meal Processing Equipment is used for the production of meat and bone meal, which is an essential ingredient for livestock feed. The machine is designed with high-quality stainless steel construction for long-lasting durability.

It has an adjustable blade that allows you to process different sizes of raw materials, including bones, animal fat, and other types of meat.

The main features of meat and bone meal processing equipment are as follows:

1. High efficiency:

The processing capacity of the meat and bone meal production line is from 1t/batch to 100t/batch or even more than 100t/batch. It can satisfy different production requirements of different customers at home or abroad.

2. Low energy consumption:

The meat and bone meal production line adopts advanced steam cooking technology, which reduces energy consumption by 20%~30%. Also, it adopts an automatic control system which helps to reduce power consumption further.

3. Low investment cost:

The meat and bone meal production line has a short construction period because all parts are standardized so it needs less space in the workshop.

4. Easy operation:

The meat and bone meal production line has an automatic control system which makes operation easier.

Technological Process Of Meat And Bone Meal Processing Equipment

Meat and bone meal is a by-product of meat-packing plants. It is also called a meat meal, bone meal, or blood meal. The raw material used to produce meat and bone meal is called “offals”, which are animal parts that are not suitable for human consumption. Meat and bone meal processing equipment consists of a series of machines that can be classified into three main groups:

1) Raw Material Preparation Group:

Put the raw materials transported by the raw material truck into the raw material warehouse for temporary storage. If it is a large animal or frozen plate raw material, advanced crushing treatment will make the material more convenient to transport, and also reduce the cooking time, and save energy consumption.

2) Processing Group:

This group includes the cooking stage (cooking machine, pan dryer), oil pressing stage (oil press machine), oil filtration and separation stage (oil vibrating screen, centrifuge), material fine crushing stage (hammer crushing unit), finished product packaging stage (automatic Packing Machine).

3) Packaging Group:

This group includes all the machines used for packaging meat or bone meal in bags or other containers. This group includes packaging machines such as mixers, fillers, and sealers which are used to package finished products into bags or pails, which can then be transported to other locations where they will be stored until they are sold and distributed to customers around the world.

Sunrise Meat And Bone Meal Processing Equipment

With the development of the economy, the demand for meat and bone meal has become more and more. Sunrise Meat And Bone Meal Processing Equipment is a kind of new high-tech product which is developed by our company.

It has many advantages such as high output, low energy consumption, simple operation, and so on. It is widely used in the meat processing industry and feedstuff industry. This machine can process raw materials into fine powder at once, which can be used as raw material for feedstuff production or animal husbandry.

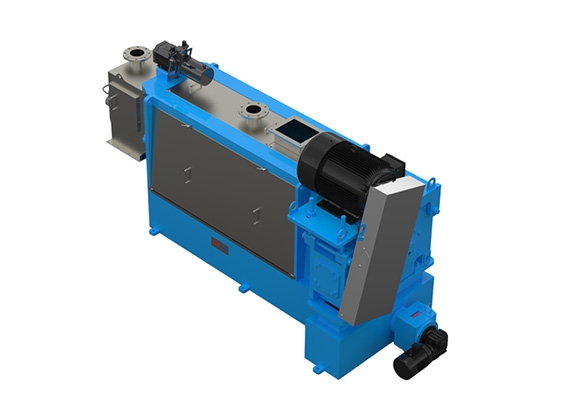

1. Fat Screw Press

The powerful Fat Screw Press produced by Jiangsu Sunrise is used for continuous mechanical extraction of oil from cooked animal by-products. Continuous oil extraction is possible with very high yields. The design is simple and effective, reducing maintenance costs. The T-screw press is fitted with a fairly short shaft and is fitted with a hydraulic choke tube at the outlet end.

During processing, the choke tube can be used to manually or automatically adjust the pressure to maintain a certain pressure. In this way, the capacity of the fat screw press can be increased and the quality of the oil/fat and press cake can be made uniform. Using the choke tube, the press can also be adjusted in the process of engineering. This technique can be used when waste production units are used to process different types of raw materials or when the amount of feed to the press varies.

2. Continuous Cooker

The Jiangsu Sunrise Continuous Cooker is the most efficient device for the continuous cooking of various animal by-products. This method of processing animal by-products is suitable for larger processing volumes, ensures uniformity of the final product, and achieves low specific energy consumption.

Inside the body of the cooking unit, there is a rotating steam heating multi-tube shaft, so the heating surface is very large. The cooking temperature can be adjusted according to processing requirements and types of raw materials. The cooking temperature can be adjusted according to processing requirements and types of raw materials.

3. Fat Filtrator

The Jiangsu Sunrise Fat Filtrator is used to screen the grease and sludge discharged from the screw press. The separator is a vibrating screen placed at an angle. Grease and fines hit the screen body, then the grease is able to penetrate the vibrating screen while the solids remain on top of the vibrating screen. With the help of inclination and vibration of the screen body, the solids are sent to the outlet.

The grease that penetrates the screen is collected on the bottom tray and then sent to the grease pump. To ensure that the grease level does not get too high, the grease collector should be fitted with a grease level gauge. The tray is equipped with inspection and cleaning doors.

The top of the separator is designed as a top cover so that inspection and cleaning can be performed from the top. During processing, the choke tube can be used to manually or automatically adjust the pressure to maintain a certain pressure.

The replacement of the sieve body can be realized through the top inspection door. The separator is supplied with a set of sieve bodies with a mesh range of 0.7~1.0mm; it is supplied as a complete set, including the motor and the replaceable sieve body.

4. Tallow Pump

The Jiangsu Sunrise Tallow Pump is used to convey the solid-containing grease squeezed out of the grease press. Stable pump body carrying underframe. The two ends of the pump body are designed with independent bearings with bearing housings, which are convenient for installation and maintenance. The main body is designed with alloy steel.

Conclusion

Sunrise sells a variety of meat meal and feather meal equipment, including feather meal machines, meat and bone meal machines, fish meal machines, etc. Sunrise offers high-quality services and the most advanced processing technologies for customers. Sunrise can provide customized solutions to fit your needs and excellent after-sales service to ensure your system operates properly at all times.

All the listed machinery from Sunrise is made up of excellent quality stainless steel or other material, complying with the standards of the European Union or America, and equipped with an internationally advanced PLC control system, which ensures their stable performance.

If you are interested in buying high-quality meat and bone meal processing equipment, please contact Sunrise Company. Sunrise can provide a full line of meat and bone meal processing equipment to you.

Categories

Recent Posts

-

Successful Case – Malaysia 50 tons of feathers per day processing project

June 20, 2025 -

Cross-country delivery in progress! Customized production line for Russian customer completed plastic packing, about to set sail!

June 16, 2025 -

From slaughtered chickens to treasure: Sunrise slaughter waste equipment leads the way to high-value utilization

June 11, 2025