How To Render Poultry Waste For Profit?

How To Render Poultry Waste For Profit?

5 Things To Take Into Consideration Before Render Poultry Waste

Render Poultry Waste is a profitable business, but you need to be careful when choosing the best rendering plant for your needs. With so many options out there, it can be hard to know what you should look for. Here are 5 things to take into consideration before rendering plant for poultry waste:

1. Size of Your Operation

The size of your operation will dictate how much poultry waste you can produce and what type of rendering plant you should invest in. If you are just starting out, it would be best to start small. You can then scale up as your business grows.

This will help you avoid the cost of purchasing a large rendering plant only to find out that you don’t have enough poultry slaughter waste to fulfill its capacity.

2. Type of Waste You Will Be Rendering

The next thing that you need to consider before rendering a plant for poultry waste is the type of waste that you will be rendering. There are different types of raw materials such as sick and dead poultry, slaughter waste feathers, viscera, raw blood, etc.

Some of these types may have a higher albumen powder content than others and this will determine how much money you can make from them when rendering plants for poultry slaughter waste.

3. How You Will Transport Your Waste To The Rendering Plant?

You also need to find out how you will transport the poultry slaughter waste from your farm to your rendering plant. If possible, try getting an agreement with one of the local farmers who has already established a good relationship with their local rendering plant.

And then let them transport the waste for free or at minimal cost until your own vehicles are ready for use or until your own trucks are ready for use.

4. What Type Of Equipment Do You Have?

There are two major types of rendering plants for poultry waste: wet rendering system and dry rendering system. The wet rendering system involves the use of water to dissolve fats from carcasses while the dry rendering system does not involve any water at all.

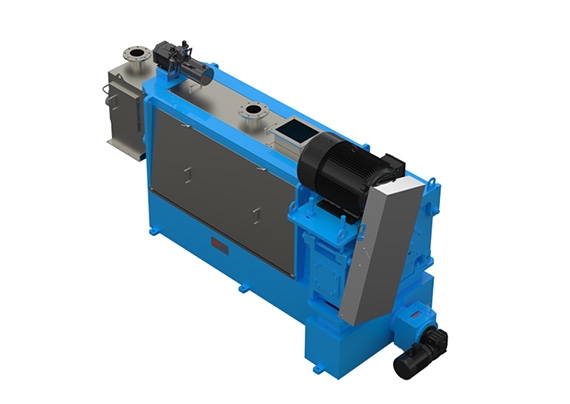

If you’re one of the many poultry producers struggling to find profitable machines for poultry waste, consider The Sunrise Company’s Machines such as Fat Screw Press. Sunrise offers a wide range of poultry rendering plant equipment, from small-batch plants to large-scale production plants. Sunrise’s machines are designed with your specific needs in mind, so you can choose the right equipment for your business.

5. What Are Their Regulations For Processing Poultry Waste?

Rendering plants are required by law to dispose of unwanted animal products responsibly and in compliance with local, state, and federal regulations.

You should know what these regulations are before setting up a poultry waste rendering plant because they will dictate how much time and money it takes to run your business.

The Economics Of Rendering Poultry Waste

Poultry processing plants produce large amounts of poultry waste such as feathers, feet, heads, and entrails. This waste can be used to produce valuable products such as animal feed, fertilizer, and energy. The use of this poultry waste can provide economic benefits to the poultry processing plant by reducing disposal costs and increasing profits.

Reduced Waste

Rendering poultry waste reduces the amount of waste in landfills because it turns organic material into valuable products like animal feed and fertilizer. This helps reduce the amount of pollution in our environment caused by landfill runoff.

Increased Revenue

Rendering poultry waste can increase revenue for farmers because they will have access to new markets for their unused products like feathers and fat. Farmers can also use this extra income to lower operating costs on their farms or reinvest it back into their operations.

Rendering poultry slaughter waste is a viable economic activity that can help improve farm profitability by creating new sources of income and reducing operating costs.

What Is A Render Poultry Waste Plant For Poultry Slaughter Waste System?

The harmless factory is a factory that reprocesses animal slaughter waste collected from farms, slaughterhouses, and breeding farms. The resulting products are typically protein powders and oils. The processing process is to crush the raw materials, high temperature and high-pressure cooking, pressing, packaging, and other processes.

Using Sunrise’s unique and proprietary system, Sunrise can transform poultry slaughter waste into valuable products – without breaking your budget.

How Does A Rendering Plant For Poultry Waste Work?

Poultry slaughter waste can be delivered to a rendering plant by truck or barge. The waste is unloaded into the rendering facility and stored until it can be processed.

Ⅰ. Remove Debris

Put the raw materials into the raw material bin, and remove the residual garbage in the raw materials, such as plastic bags, metal objects, etc., which helps to reduce the damage to the equipment caused by such substances and the pollution to the final product.

Ⅱ. Crushing

Raw materials enter the crusher and are separated in a closed environment. Under the action of the reamer, they are broken into 4-5cm pieces of meat, so as to shorten the cooking time during cooking and save time and energy consumption.

Ⅲ.Cooking

The material is fed into the cooking machine through the screw, and the mouth of the tank is automatically closed when it reaches the rated weight. And then the heating and pressure sterilization starts. After the temperature in the tank reaches 140 degrees (0.4Mpa), the pressure is maintained for 30 minutes (pressure and temperature can also be adjusted according to different materials).

And then enter the drying stage, using the low-temperature vacuum drying method, after drying for 3-4 hours (adjust the drying time according to the moisture content of the material), the moisture content of the material will drop to ≤20%, and the oil content will be about 30%. Using batch processing, the entire process of feeding, cooking, drying, and discharging takes 5-6 hours.

Ⅳ. Pressing

The semi-finished materials are sent into the heating pot of the Fat Screw Press through the screw conveyor. And then slowly enter the press chamber of the Fat Screw Press for oil separation, reducing the oil content of the materials to 10-12%, and obtaining meat and bone meal and oil.

Ⅵ. Filtering

The fat from the rendered poultry slaughter waste is filtered by a fat filtrator. Fat filtrator is designed for screening fat and sludge from expeller presses. The solid material recovered will be composed mainly of protein, which can be further processed into pet food, livestock feed, or fertilizer.

Ⅴ. Packaging

The protein solids are then cooled and dried before they are packaged for sale as meat meals or animal feed.

Why Use Rendering Plants for Poultry Waste?

There are many reasons why people choose to use rendering plants for their poultry waste disposal needs. They include:

Sustainability

By using chicken waste rendering plants, you can keep poultry meat out of landfills and recycle it into usable poultry by-products that may even help you save money on other products in your business.

Cleaner Environment

By disposing of your dead animals at a rendering plant instead of dumping them on your property, you are helping keep your environment clean and free of any potential hazards that could harm wildlife or children playing outside.

Better Quality Products

Using a rendering plant will result in better quality products than if you had just thrown away all of your dead animals in one place.

How To Build A Render Poultry Waste?

Poultry waste is an important source of raw material for rendering plants. The rendering process can transform chicken and turkey feathers into high-quality protein meal that is used as an ingredient in pet foods and livestock feed. Chicken manure can be used as compost or fertilizer. There are several steps that need to be taken before you can build your own rendering plant for poultry waste. These include:

1) Planning And Designing The Plant:

This involves deciding on the location of the plant, designing a layout for it, and planning how you will go about setting it up. You should also consider factors like utility lines and road access when planning where to put your plant.

2) Finding Equipment And Supplies:

You need equipment like mixers, blenders, and grinders as well as supplies such as grease traps, filters, and pipes.

3) Getting Licenses And Permits:

You will need licenses from state agencies such as environmental protection agencies and permits from local authorities like health departments.

Conclusion

The Sunrise Company is a reliable rendering plant machine manufacturer that can help you build the Render Poultry Waste. The right rendering plan can turn the problems of poultry farm wastes into profit opportunities.

If you’ve been considering poultry waste as an injection of new business and revenue, encourage you to contact Sunrise Company. With our experience, there are several ways Sunrise can help you increase profitability through off-spec rendering.