Custom Meat Bone Meal Machine by SunRise: Meeting Diverse Industry Needs

Custom Meat Bone Meal Machine by SunRise: Meeting Diverse Industry Needs

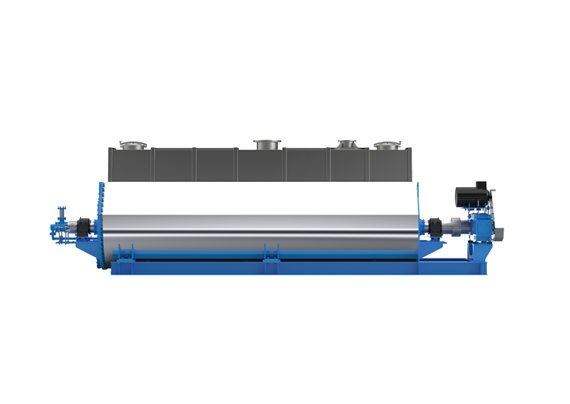

In the world of industrial processes, customization is key to efficiency and effectiveness. The Meat Bone Meal Machine offered by SunRise stands as a prime example of tailored engineering, catering to a plethora of industries unique requirements. This innovative machine is a comprehensive solution that efficiently processes meat and bone waste, contributing to both sustainable waste management and the creation of valuable byproducts. Let’s delve into the intricate configuration of this machine, highlighting its various components and their roles.

Meat bone meal machines are specialized pieces of equipment designed to process animal bones and meat scraps into valuable meat bone meals. This meal is a nutrient-rich product widely used in animal feed, fertilizers, and other applications. Choosing the right machine is vital for achieving optimal product quality, ensuring safety and efficiency, and minimizing operational costs. SunRise, a reputable name in the industry, offers a range of meat bone meal machines tailored to various manufacturing needs.

Cutting-Edge Configuration: Transforming Waste into Value

1. Ionization Tower: Paving the Way for Cleaner Emissions

Ionization tower is an important component for reducing waste gas.This tower effectively reduces harmful emissions, showcasing SunRise’s commitment to environmental responsibility. By ionizing exhaust gases, this tower plays a pivotal role in minimizing the machine’s ecological footprint.

2. Advanced Exhaust Abatement and Lamella Pump

Working in tandem with the Ionization Tower is an advanced exhaust abatement system. This collaboration ensures that harmful gases are neutralized and filtered before release. The Lamella Pump complements this setup by efficiently channeling gases through the exhaust abatement process, further enhancing the machine’s emission control capabilities.

3. Seamless Material Handling: Screw Conveyor and Disc Dryer

Efficiency in material handling is the cornerstone of any industrial process. SunRise’s Meat Bone Meal Machine incorporates a Screw Conveyor and Disc Dryer, which works harmoniously to transport and dry the processed material. This streamlined handling process not only saves time but also optimizes resource utilization.

4. Consistent Cooking with Continuous Cooker

The Continuous Cooker is a standout feature that ensures uniform cooking of the meat and bone mixture. This consistency is paramount in obtaining high-quality end products, making it a pivotal component in the entire process.

5. Tailored for Versatility: Material Bin and Customizable Configurations

SunRise understands the diverse requirements of different industries. The inclusion of a Material Bin allows for efficient storage and distribution of processed material. Moreover, the machine’s modular design enables custom configurations, ensuring that it can be adapted to meet specific industry needs seamlessly.

Delivering Excellence Across Industries

1. Animal Feed Industry: Creating Nutrient-Rich Feed

In the animal feed industry, the Meat Bone Meal Machine plays a crucial role in producing nutrient-rich animal feed. The meticulous processing ensures that the final product is safe, nutritious, and meets the stringent quality standards of the industry.

2. Agriculture and Fertilizer Production: Fostering Growth and Sustainability

Agriculture and fertilizer production benefit from the byproducts of the Meat Bone Meal Machine. The bone meal, rich in calcium and phosphorus, serves as an excellent organic fertilizer. This synergy between waste management and agricultural needs contributes to sustainable farming practices.

3. Renewable Energy Sector: Extracting Valuable Components

SunRise’s machine extends its utility to the renewable energy sector. By extracting fats and oils through the Fat Screw Press, the machine contributes to the production of biofuels. This dual-purpose capability showcases its adaptability to emerging energy needs.

4. Environmental Conservation: Reducing Waste and Pollution

Beyond the specific industries mentioned, the Meat Bone Meal Machine aligns with broader environmental conservation efforts. By transforming meat and bone waste into valuable resources, the machine reduces landfill burden and minimizes pollution risks.

Factors to Consider When Choosing a Meat Bone Meal Machine

1. Processing Capacity and Size:

One of the primary considerations when selecting Meat Bone Meal Machine is its processing capacity. Manufacturers need to assess the amount of raw material they handle daily and choose a machine that can handle that volume. SunRise provides machines with different processing capacities to suit both small-scale and large-scale operations.

2. Mechanical Efficiency and Durability:

A meat bone meal machine should be durable enough to withstand the rigors of constant operation. Look for machines constructed from high-quality materials, as they are likely to have a longer lifespan and require fewer maintenance interventions. SunRise takes pride in crafting robust machines designed for longevity.

3. Automation and User-Friendly Features:

Automation can significantly enhance operational efficiency by reducing manual labor requirements. SunRise’s meat bone meal machines often come equipped with user-friendly controls and automation features, streamlining the production process and minimizing the risk of human errors.

4. Safety Measures:

Working with heavy machinery demands stringent safety measures. When choosing a meat bone meal machine, manufacturers should prioritize machines with proper safety features, such as emergency stop buttons and protective covers. SunRise places a strong emphasis on the safety of its machines to protect both operators and the manufacturing process.

5. Energy Efficiency:

Energy efficiency is a key factor in today’s environmentally conscious world. Opting for an energy-efficient meat bone meal machine can significantly reduce operational costs and minimize the carbon footprint of the manufacturing process. SunRise’s machines are designed with energy efficiency in mind, helping manufacturers save on energy expenses.

SunRise: Pioneering Customized Solutions

In the realm of industrial machinery, SunRise stands out as a pioneer of customized solutions. The Meat Bone Meal Machine encapsulates their dedication to understanding industry nuances and creating equipment that addresses unique challenges. From exhaust abatement to material handling, each component is meticulously engineered to maximize efficiency and cater to diverse industries.

SunRise has established itself as a reputable manufacturer in the meat bone meal industry. With years of experience and a commitment to innovation, they offer a wide range of meat bone meal machines that cater to different production needs. Their machines are engineered with the latest technology, ensuring high processing efficiency, consistent product quality, and user-friendly interfaces.

Conclusion

In a world increasingly focused on sustainability and resource optimization, SunRise’s Meat Bone Meal Machine serves as a shining example of how innovation can drive positive change. Through collaboration, adaptation, and customization, SunRise paves the way for industries to enhance their operations while contributing to a greener future.