Revolutionizing Protein Rendering: The Protein Rendering Machine

Revolutionizing Protein Rendering: The Protein Rendering Machine

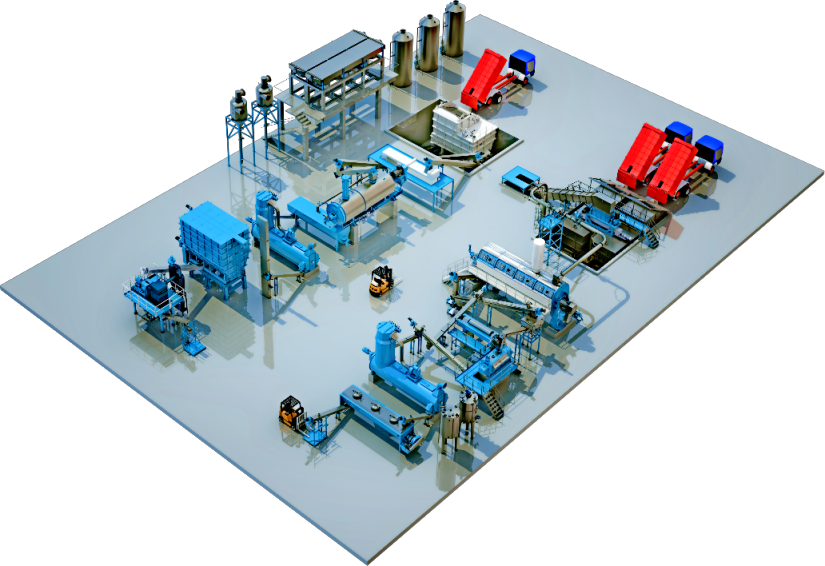

The protein rendering machine is a sophisticated apparatus designed for the conversion of animal byproducts and other food waste into protein-rich materials. This innovative process, originating in the mid-1900s, was developed to extract valuable nutrients from waste products, rendering them suitable for use as either fertilizer or animal feed.

These protein rendering machines are commonly located in slaughterhouses, efficiently transforming various animal parts into valuable products. They are also deployed on farms, where they play a pivotal role in converting manure into nutrient-rich fertilizer for crop cultivation. Remarkably automated, these systems demand minimal human intervention once they are established and operating seamlessly.

Traditional Protein Rendering in Structural Biology

Traditional protein rendering primarily involves the representation of three-dimensional protein structures on two-dimensional surfaces like computer screens or paper. This visualization serves as a cornerstone for researchers in fields such as biochemistry and molecular biology, aiding their comprehension of protein structural features and functionalities.

Several common methods and tools are employed in traditional protein rendering:

– Wireframe Models

In the early stages of protein rendering, wireframe models were the go-to choice for illustrating a protein’s fundamental backbone structure. This technique simplifies the representation of secondary and tertiary protein structures, elucidating the interconnection of amino acid residues.

– Molecular Surface Models

Molecular surface models delineate a protein’s accessible and inaccessible surface regions. These models often utilize color coding to denote various properties, such as hydrophobic and hydrophilic areas, facilitating a deeper understanding of the protein’s function.

– Software Tools

Diverse software tools and programs, including PyMOL, Chimera, VMD (Visual Molecular Dynamics), and Jmol, cater to the rendering of protein structures. These tools offer an array of rendering options, permitting researchers to manipulate and analyze protein structures effectively.

Recent years have witnessed remarkable strides in technology and computational biology, ushering in more advanced and interactive protein visualization methods. This includes the incorporation of virtual reality (VR) and augmented reality (AR) tools, delivering immersive experiences for researchers exploring protein structures. Nevertheless, traditional protein rendering retains its pivotal role in structural biology, serving as an indispensable means of conveying intricate structural information to scientists and students alike.

The Evolution of Protein Visualization

The history of protein rendering closely intertwines with the evolution of techniques and technologies for depicting the three-dimensional structures of proteins. Below is a concise overview of pivotal milestones in the history of protein visualization:

Early Models and Diagrams (1950s – 1960s):

Protein rendering commenced with early endeavors to portray protein structures in a two-dimensional format. Linus Pauling and Robert Corey introduced fundamental concepts like the alpha helix and beta sheet, employing rudimentary diagrams and wireframe models to convey these structures.

Emergence of Pioneering Software Tools (1990s):

The 1990s witnessed the advent of groundbreaking software tools, including RasMol and Chime. These tools empowered researchers to explore and manipulate protein structures in three dimensions on personal computers, marking a revolutionary juncture in structural biology.

Immersive Technologies (2010s – Present):

Recent years have ushered in remarkable strides in virtual reality (VR) and augmented reality (AR), enabling researchers to interact with and visualize protein structures within immersive environments. These technologies hold immense promise in reshaping the methodologies scientists employ to investigate and comprehend proteins.

Throughout this historical journey, the realm of structural biology has undergone continual transformation. Researchers have consistently devised novel techniques and software tools to enhance the representation and visualization of protein structures. Today, a vast array of rendering techniques and tools stands ready, granting scientists unprecedented insights into the intricate facets of protein molecules and their multifaceted functionalities.

Advantages of the Protein Rendering Machine

The utilization of a protein rendering machine offers a spectrum of benefits, encompassing:

Environmental Friendliness and Chemical-Free Practices:

Protein rendering stands as an environmentally friendly practice that harnesses animal by-products, preventing their wastage and promotes responsible resource use. It significantly curtails the volume of organic waste destined for landfills, thus minimizing the environmental toll of waste disposal.

Maximized Value and Enhanced Safety:

The products yielded through rendering, including protein meals and fats, find application across diverse industries, from animal feed to pet food, cosmetics, and biodiesel production. This multifaceted utility generates revenue while reducing the demand for virgin resources. Furthermore, proper rendering processes serve as a crucial safeguard, eliminating pathogens and diseases that may be present in animal by-products, and ensuring the ultimate safety of these materials for use in animal feed and other applications.

Harmonizing Environmental Responsibility with Economic Prosperity:

Rendering facilities conscientiously adopt measures for odor control and pest management, mitigating the negative environmental and community repercussions associated with handling animal by-products. Simultaneously, the rendering industry fosters local economic growth by providing employment opportunities in regions where these facilities are situated.

Cultivating a Sustainable Tomorrow:

Rendering aligns seamlessly with sustainability principles by repurposing organic materials and contributing to the circular economy. Through the transformation of organic matter into valuable products, rendering actively curtails the greenhouse gas emissions linked to the decomposition of organic waste in landfills.

The protein rendering machine not only champions responsible resource management but also fosters economic growth, safeguards environmental well-being, and contributes to the pursuit of a sustainable future.

How the Protein Rendering Machine Operates

The precise functioning of a protein rendering machine can vary based on its design and capabilities. However, here is a general outline of how such a machine typically functions:

The Journey Begins: Collection, Preparation, and Transformation

1) Collection and Preparation:

Animal by-products, including bones, carcasses, and various organic materials, are sourced from slaughterhouses, meat processing plants, and other origins. These raw materials undergo a thorough sorting and cleaning process to eliminate non-renderable elements such as hair, feathers, and foreign objects.

2) Cooking or Heating:

The prepared animal by-products are exposed to elevated temperatures through processes like steam cooking, dry rendering, or wet rendering. The choice of method hinges on the specific material being processed and the desired end products.

The Art of Precision: Separation, Drying, and Quality Assurance

1) Separation:

Post-cooking or heating, the mixture of fat, protein, and other components undergoes meticulous separation. This can be achieved through various techniques like centrifugation, pressing, or decanting, with the primary objective being the isolation of fat (tallow) and protein-rich material (meat and bone meal).

2) Drying:

The segregated protein and fat components are typically subjected to a drying process, reducing moisture content and extending shelf life. Various drying methods, such as air drying, drum drying, or spray drying, are employed to meet specific product requirements.

3) Quality Control:

Stringent quality control measures are implemented to ensure that the final products align with industry standards and regulatory prerequisites. This encompasses assessments for moisture content, protein levels, and the absence of contaminants.

Sealed for Purpose: Packaging and the Journey to Diverse Industries

Upon successful processing and meeting quality benchmarks, the protein meal and fat are meticulously packaged into suitable containers, ranging from bags to bulk containers. These packaged products are then distributed across various industries. Protein meal finds application in animal feed, pet food, and fertilizer production, while fat serves in cosmetics, biodiesel production, and an array of other applications.

This overview encapsulates the operational essence of a protein rendering machine, underscoring its role in transforming raw materials into valuable resources that cater to the needs of diverse industries.

CONCLUSION

The protein rendering machine stands as a pivotal milestone in the rendering industry, revolutionizing the processing of animal by-products and their conversion into valuable commodities such as protein meals and fats.

In essence, the protein rendering machine serves as a vital component in the responsible and efficient stewardship of animal by-products, holding the promise of reshaping the rendering industry and advancing us toward a more sustainable and resource-efficient future. As technology continues its relentless progress, we anticipate ongoing innovations in rendering processes, further amplifying efficiency and diminishing environmental footprints.