Slaughter Waste Rendering Plant Disposal Methods: New Ideas for Win-Win Environmental Protection and Benefits

Slaughter Waste Rendering Plant Disposal Methods: New Ideas for Win-Win Environmental Protection and Benefits

The treatment of slaughter waste (RENDERING PLANT) is an important issue of environmental protection and economic development. This paper systematically describes the effective treatment methods of slaughtering waste from the perspective of environmental protection and benefit, and provides practical reference for industry practitioners.

In the rapid development of the modern farming and slaughtering industry, the treatment of slaughter wastes has become an increasingly prominent issue. These wastes include solid wastes such as animal offal, bones, blood, etc., as well as sewage generated during washing and treatment. How to treat these wastes scientifically and efficiently is not only related to the protection of the ecological environment, but also involves the long-term development of the industry and the enhancement of economic benefits.

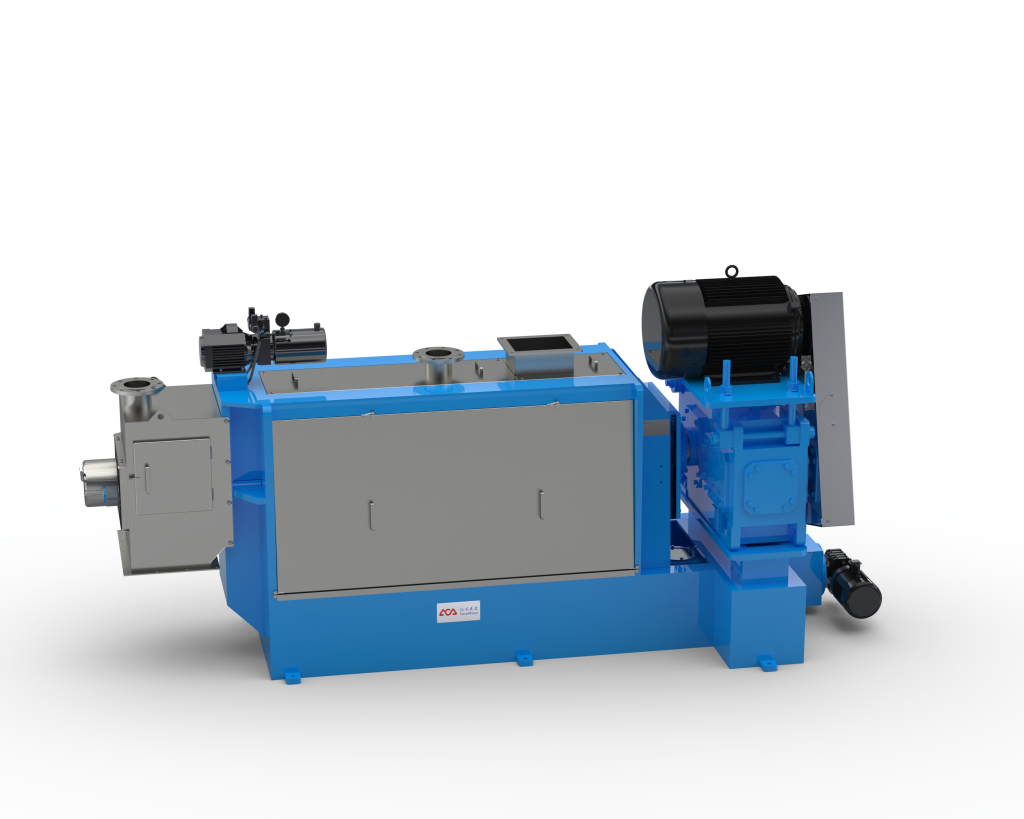

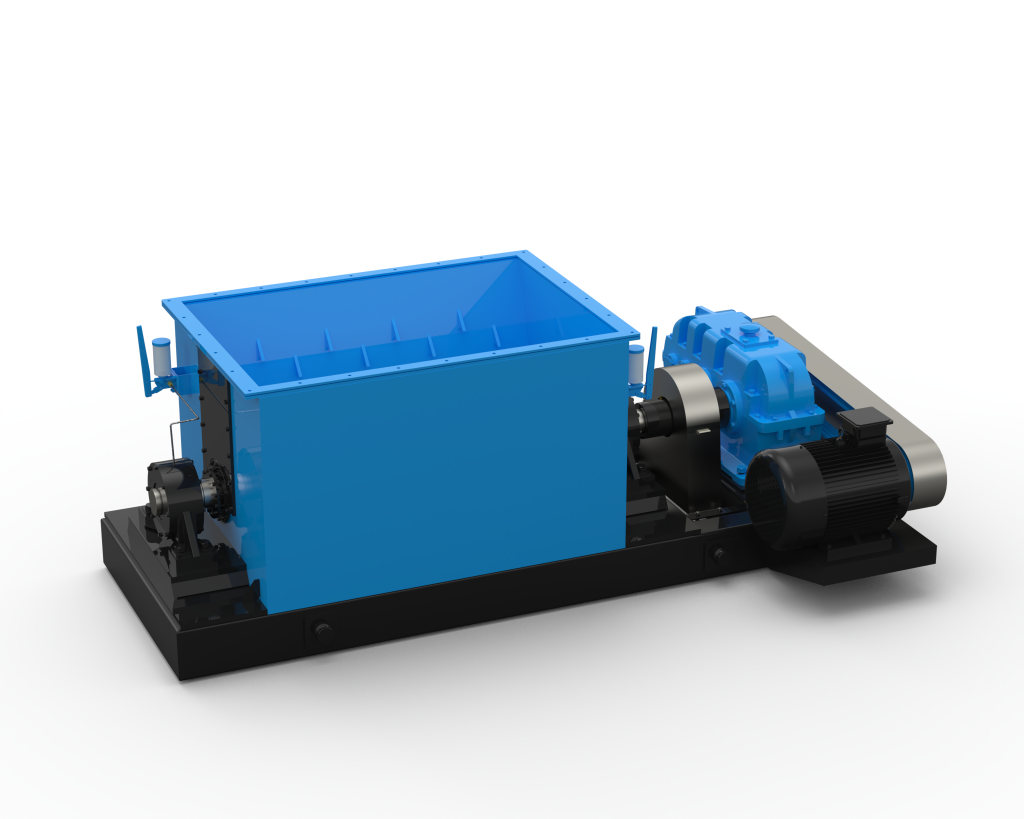

Sunrise Environmental Equipment Co., Ltd. specializes in manufacturing, efficient and durable slaughter waste Rendering plant equipment.

The severity of the slaughter waste problem

Slaughter waste, if not handled properly, can cause serious environmental pollution:

Odor Pollution: The waste emits a strong odor after rotting, which greatly affects the lives of nearby residents.

Water pollution: wastewater contains a large amount of organic matter, fat and pathogenic microorganisms, discharged into the water body will lead to eutrophication of the water body, endangering the water ecosystem.

Soil Pollution: Untreated waste landfilled at will will cause pathogenic bacteria to grow in the soil and pollute the land resources for a long time.

From the economic point of view, these wastes are a great waste of resources without effective treatment. According to statistics, the protein and fat rich in slaughter waste, if utilized, can be transformed into high value-added products, such as animal feed, organic fertilizer and bioenergy.

Sunrise Environmental Equipment Co., Ltd. specializes in manufacturing, efficient and durable slaughter waste Rendering plant equipment.

Limitations of traditional treatment methods

In the past, many slaughtering enterprises mainly disposed of their wastes through simple methods such as landfill, incineration or direct discharge. However, these methods have obvious defects:

Landfill: occupies land resources and is prone to breeding harmful microorganisms, causing long-term pollution.

Incineration: high cost, easy to produce dioxin and other toxic gases, causing secondary pollution to the air.

Direct discharge: extremely destructive to the surrounding environment and prone to social and legal disputes.

Therefore, the industry is in great need of introducing scientific, environmentally friendly and economical waste treatment technology to solve these problems and realize resource utilization.

Senrong environmental protection slaughter waste treatment equipment! Resourceful reuse!

Animal feed materials: Senrong environmental protection through animal protein conversion technology, slaughter waste, such as viscera, blood, bones, feathers, etc. into meat meal, bone meal, meat and bone meal, blood meal, feather meal, etc. can be used as a feed ingredient to provide a rich source of protein.

Biodiesel: Sen Rong Environmental Protection extracts oil and grease from fat waste, and the extracted oil and grease can be the raw material for biodiesel.

With the support of the above technologies, the treatment of slaughter waste not only reduces environmental pollution, but also creates additional income for the enterprise.

Typical cases of slaughter waste treatment

In recent years, many enterprises at home and abroad are using Senrong Environmental Protection’s slaughtering waste treatment equipment, which has achieved remarkable results, the following are some successful practice cases:

Shandong Fengxiang Feather Powder Case

The enterprise introduced the fully automatic waste treatment equipment, through the feather dewatering, continuous hydrolysis process, the average daily amount of waste treatment reaches hundreds of tons. The feather meal produced by the company is used as raw material for animal feed, saving millions of dollars in feed costs annually.

Hebei Torui meat and bone meal case

The enterprise introduces fully automatic slaughtering waste treatment equipment, through the viscera, bones, blood high temperature and high pressure chemical processing, into animal protein meat powder, bone meal and blood powder. The waste is transformed into high-value animal protein.

Hebei Yimu harmless case

The enterprise introduces fully automatic livestock and poultry harmless treatment equipment, through high temperature and high pressure disinfection and sterilization, the livestock and poultry carcasses are transformed into organic fertilizer.

Challenges and Responses to Slaughter Waste Treatment

Despite the increasing sophistication of modern treatment technologies, the implementation process still faces the following challenges:

High initial investment costs

The initial investment in many treatment equipment and technologies is large, discouraging some small and medium-sized enterprises. In this regard, enterprises can actively apply for government subsidies or seek cooperation with professional environmental protection companies to share the financial pressure.

High technical management requirements

Waste treatment requires technical support and the participation of professionals, which can be solved by training internal staff or outsourcing services.

Insufficient public awareness

Residents in the vicinity of certain abattoirs may have misconceptions about treatment facilities, such as concerns about pollution or health risks associated with the new technology. Enterprises need to enhance publicity and communication to dispel public concerns through open visits and transparency of information.

Future Trends

With the increasingly stringent national environmental protection policies, the slaughter waste treatment industry is developing towards intelligence, resourcefulness and low-carbonization:

Intelligent Monitoring and Management

Utilizing IoT technology to monitor key indicators (e.g. gas emissions, effluent treatment efficiency) in the waste treatment process in real time to ensure efficient and reliable operation.

Circular Economy Model

Promote the synergistic development of agriculture, energy and manufacturing industries through the deep processing and efficient use of waste, and maximize the value of “turning waste into treasure”.

Improvement of Policies and Industry Standards

The government will further introduce incentives, standardize industry standards, and provide more policy support and market orientation for enterprises.

Slaughter waste treatment is not only an urgent need for environmental protection, but also a necessary path for industrial upgrading. Driven by science and technology, this field is full of opportunities and provides a new direction for sustainable development for industry practitioners.

Sunrise Environmental Equipment Co., Ltd. specializes in manufacturing, efficient and durable slaughter waste Rendering plant equipment.

Categories

Recent Posts

-

Batch Cooker, Meat and Bone Meal Production Equipment, Environmentally Friendly and Highly Efficient Equipment, Chemical Skimming Equipment, Meat and Bone Meal Processing

29 11 月, 2024 -

Slaughter Waste Rendering Plant Disposal Methods: New Ideas for Win-Win Environmental Protection and Benefits

28 11 月, 2024 -

Rendering plant of meat and bone meal production equipment: creating an environmentally friendly and efficient solution for the farming industry

22 11 月, 2024