Mastering Workshop Safety: Guide to Cyclone Dust Collector

Mastering Workshop Safety: Guide to Cyclone Dust Collector

In any industrial setting, ensuring the safety and well-being of workers is of paramount importance. One area that often poses risks to both health and safety is airborne dust and particulate matter. Fortunately, the Sunrise Cyclone Dust Collector, a reliable air pollution control device, offers an effective solution to mitigate these hazards.

The Sunrise Cyclone Dust Collector caters to a wide range of industries, including feather meal projects, meal plants, fat plants, rendering plants, and woodworking operations. The primary beneficiaries of this product are professionals and workers in these fields who encounter airborne dust and particulate matter on a daily basis.

What are Cyclone Dust Collectors?

Cyclone dust collectors are devices used to capture and remove dust particles from the air in a workshop or industrial setting. They employ a combination of centrifugal force and gravity to separate the dust particles from the air stream. The primary components of a cyclone dust collector include an inlet, an outlet, a cylindrical body, and a cone-shaped bottom.

As the dusty air enters the inlet, it is forced into a swirling motion within the cylindrical body, causing the heavier dust particles to be flung towards the walls and fall into the cone-shaped bottom. The cleaned air is then discharged through the outlet, leaving the workshop environment cleaner and healthier.

Key Technical Parameters: Cyclone Dust Collectors

When selecting a cyclone dust collector for a specific application, it is crucial to consider the technical parameters provided by the manufacturer. In this case, let’s look at the technical parameters for the cyclone dust collectors manufactured by SunRise:

- XFFL900: Cylinder diameter of 900 mm, height of 3030 mm, and weight of 390 kg.

- XFFL1000: Cylinder diameter of 1000 mm, height of 3420 mm, and weight of 530 kg.

- XFFL1500: Cylinder diameter of 1500 mm, height of 5652 mm, and weight of 1450 kg.

The Problems Faced by the Manufacturer:

1. Health Hazards: Exposure to airborne dust can lead to respiratory issues, allergies, and even more severe health conditions. Workers in the mentioned industries are particularly vulnerable to these risks due to their prolonged exposure to dust-filled environments.

2. Safety Concerns: Accumulated dust particles can pose fire and explosion hazards, endangering both the workers and the facilities they operate in. The potential for workplace accidents increases when dust obstructs visibility or accumulates on surfaces.

3. Equipment Performance: Dust accumulation on machinery and equipment can hinder their performance, leading to frequent breakdowns, decreased efficiency, and increased maintenance costs. This can result in production delays and financial losses.

How the Sunrise Cyclone Dust Collector Solves These Problems:

1. Health Protection: By effectively removing dust and particulate matter from the air, the Sunrise Cyclone Dust Collector significantly reduces workers’ exposure to harmful airborne contaminants. This promotes a healthier working environment and helps prevent respiratory ailments and allergies.

2. Safety Assurance: The Cyclone Dust Collector’s ability to separate heavy particles from the air stream eliminates the risk of dust accumulation, minimizing the likelihood of fire and explosion hazards. The improved air quality also enhances visibility, reducing the potential for accidents.

3. Enhanced Equipment Efficiency: With its efficient dust collection mechanism, the Sunrise Cyclone Dust Collector prevents dust accumulation on machinery and equipment. This leads to improved performance, reduced downtime, and lower maintenance costs, ultimately maximizing productivity and profitability.

Product Features and Benefits: Cyclone Dust Collector

1. Efficient Dust Separation: The Sunrise Cyclone Dust Collector utilizes centrifugal force to separate heavy particles, ensuring high dust collection efficiency and reliable performance.

2. Easy Installation: The product is designed for hassle-free installation, allowing for quick integration into existing systems without significant disruptions.

3. Low Maintenance: The Cyclone Dust Collector requires minimal maintenance, saving valuable time and resources for businesses.

4. Durable Construction: Manufactured by SunRise, a trusted brand, this dust collector boasts a robust build quality that ensures longevity and durability in demanding industrial environments.

5. Versatile Applications: From feather meal projects to rendering plants and woodworking operations, the Sunrise Cyclone Dust Collector is adaptable and can effectively address various industry-specific dust control requirements.

Safety Tips and Best Practices: Mastering Workshop Safety with Cyclone Dust Collectors

Workshops are bustling hubs of creativity and productivity, where individuals bring their ideas to life. However, amidst the whirlwind of activity, it’s crucial to prioritize safety. Dust and debris generated during woodworking and other workshop activities can pose health risks if not properly managed. Cyclone dust collectors, such as those manufactured by SunRise, offer an effective solution to mitigate these hazards.

1. Understand the Hazards:

Before diving into safety practices, it’s essential to understand the hazards associated with airborne dust particles in workshops. Fine dust can be a respiratory irritant and may cause long-term health problems. It can also create a combustible atmosphere, increasing the risk of fire and explosions. By recognizing these hazards, you can better appreciate the importance of investing in reliable dust collection systems like SunRise’s cyclone dust collectors.

2. Invest in a High-Quality Cyclone Dust Collector:

Choosing a reputable manufacturer like SunRise ensures that you have a reliable and efficient cyclone dust collector. Look for features such as strong suction power, durable construction, and efficient filtration systems. A high-quality dust collector will effectively capture and remove dust and debris, maintaining a clean and safe workshop environment.

3. Proper Installation and Maintenance:

Follow the manufacturer’s instructions for installing the cyclone dust collector correctly. Ensure it is securely connected to the workshop equipment generating dust, such as saws, sanders, or routers. Regularly inspect the system for any leaks, loose fittings, or damaged components. Perform routine maintenance, including cleaning filters, to ensure optimal performance and longevity.

Conclusion

The Sunrise Cyclone Dust Collector emerges as an indispensable tool for mastering workshop safety in industries where airborne dust poses significant risks. By offering efficient dust collection, improved health protection, enhanced safety, and increased equipment performance, this product empowers businesses to create safer, healthier, and more productive working environments. Invest in the Sunrise Cyclone Dust Collector today and experience the transformation it brings to your workplace safety and overall operational excellence.

Categories

Recent Posts

-

What is harmless treatment of sick and dead animals and poultry(rendering plant) A Key Initiative to Protect the Ecological Environment and Food Safety.

March 6, 2025 -

How does Sunrise rendering plant equipment destroy avian influenza viruses in livestock poultry carcasses

March 5, 2025 -

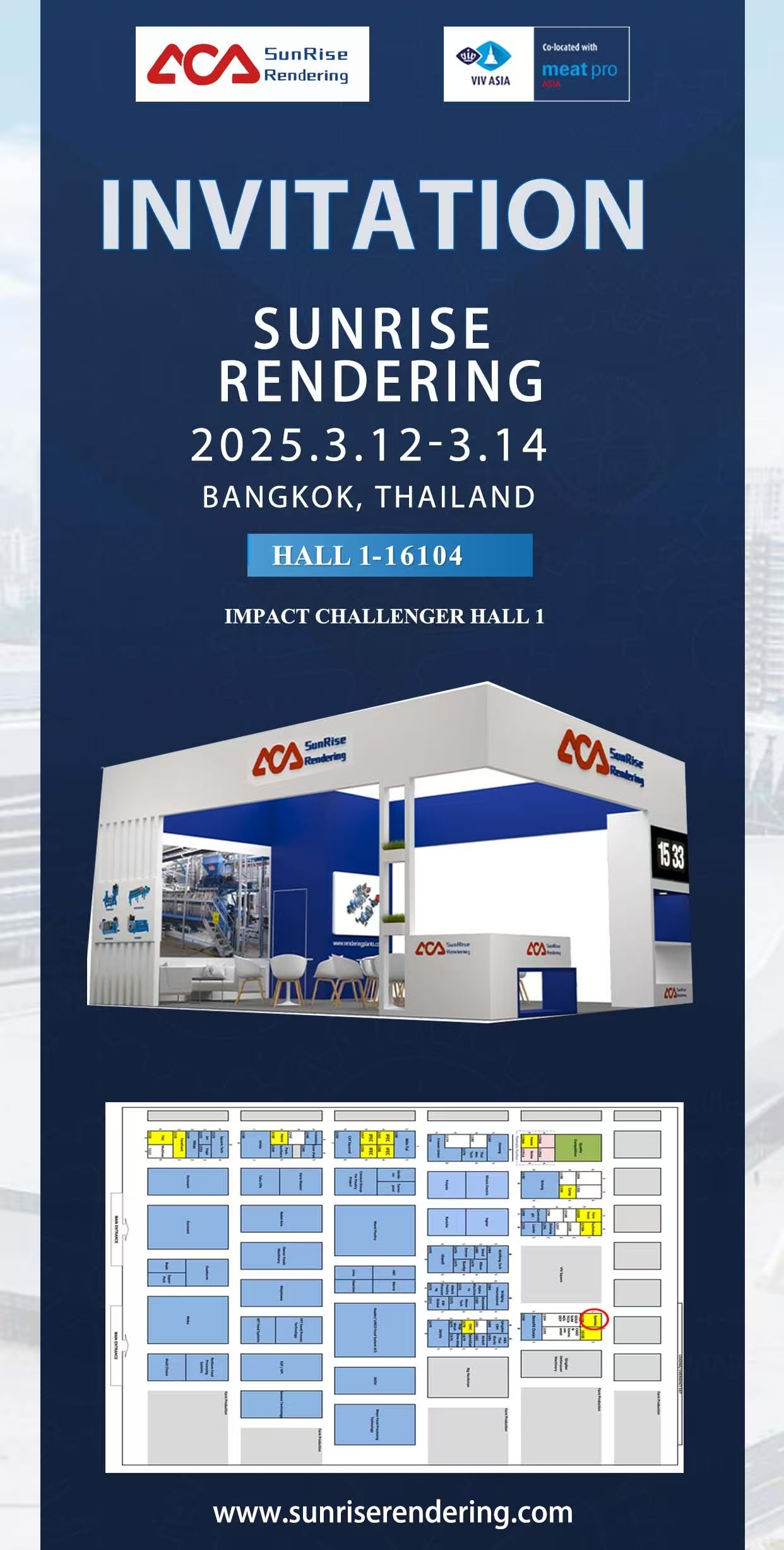

Sunrise Rendering Thailand Exhibition

March 5, 2025