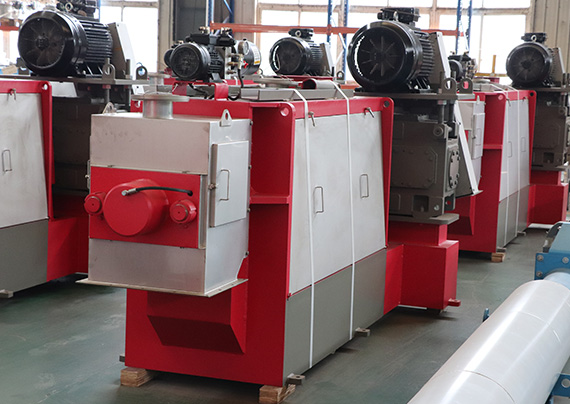

Fat Screw Press

Efficient Oil Screw Press for Animal Fat Processing

In the dynamic world of animal fat processing, our oil screw press emerges as a game – changing solution, this high – performance equipment is designed to extract high – quality animal fats with remarkable efficiency and reliability.

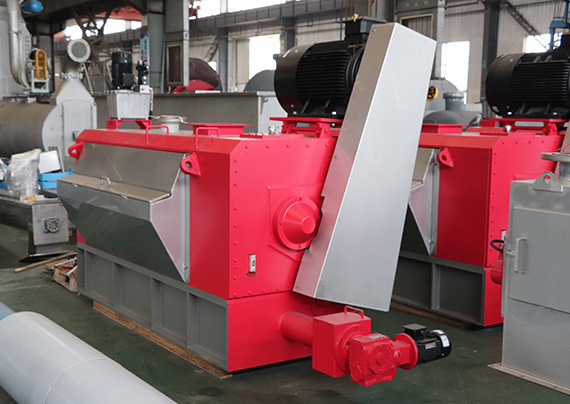

Robust Design for Optimal Performance

Our oil screw press features a rugged construction, built with heavy – duty materials that can withstand the rigors of continuous operation. The main body is crafted from durable steel, ensuring long – lasting performance even under challenging working conditions. The screw mechanism, a crucial component of the press, is precision – engineered to provide consistent and powerful pressure. It is made from high – strength alloy steel, which not only resists wear and tear but also enables smooth and efficient operation.

High – Efficiency Fat Extraction

When it comes to processing animal fat, efficiency is key. Our oil screw press is capable of achieving an impressively high fat extraction rate. Whether you are dealing with lard from pork fat, tallow from beef or mutton fat, or other types of animal fats, the press can effectively separate the fat from the solid residue. The unique design of the screw and the barrel allows for a gradual and thorough pressing process. As the animal fat – containing materials are fed into the press, the rotating screw pushes them forward, while applying increasing pressure. This pressure forces the fat out through small openings in the barrel, leaving behind a dry and residue – free cake.

Adaptable to Various Animal Fat Sources

One of the great advantages of our oil screw press is its versatility. It can handle a wide range of animal fat sources. From the fatty tissues of livestock such as pigs, cows, and sheep to the fats obtained from poultry processing, the press can adapt to different characteristics of these materials. For example, when processing pork fat, which has a relatively soft texture, the press can be adjusted to apply the right amount of pressure to ensure maximum fat extraction without over – processing. On the other hand, when dealing with beef tallow, which may be harder and require more force, the press is designed to deliver the necessary pressure to break down the fat cells and release the valuable fat.

Environmentally – Conscious Processing

In today’s world, environmental sustainability is a top priority. Our oil screw press is designed with this in mind. The processing method is energy – efficient, consuming less power compared to some traditional fat extraction methods. Moreover, the dry cake residue left after fat extraction can be further processed or used as a valuable by – product, such as in animal feed production or as a source of organic matter for composting. By maximizing the utilization of resources and minimizing waste, our oil screw press contributes to a more sustainable approach to animal fat processing.

If you are looking to enhance your animal fat processing capabilities, our oil screw press is the ideal choice. It combines advanced technology, high – quality construction, and user – friendly features to deliver outstanding results. Contact us today to learn more about our oil screw press and how it can revolutionize your animal fat processing operations.

Categories

Recent Posts

-

Animal protein meal plays an important role in feed

March 27, 2025 -

Efficient Oil Screw Press for Animal Fat Processing

March 21, 2025 -

What is harmless treatment of sick and dead animals and poultry(rendering plant) A Key Initiative to Protect the Ecological Environment and Food Safety.

March 6, 2025