Air Cooled Condenser / Air Cooled Condenser Manufacturers

- Brand: Sunrise

- Application: Feather Meal Project | Fish Meal Plant | Meal Plant & Fat Plant | Rendering Plant

- Shipping: Air / Sea / Train / Truck

- Warranty Period: One Years with Lifelong Free Service

- Alias: Air cooled condenser manufacturers / Air cooled condenser chiller

Description

Basic Application

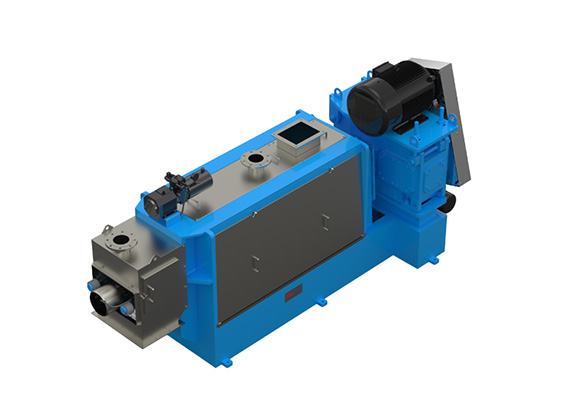

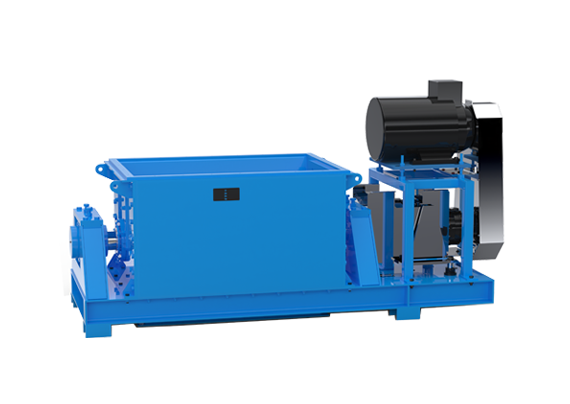

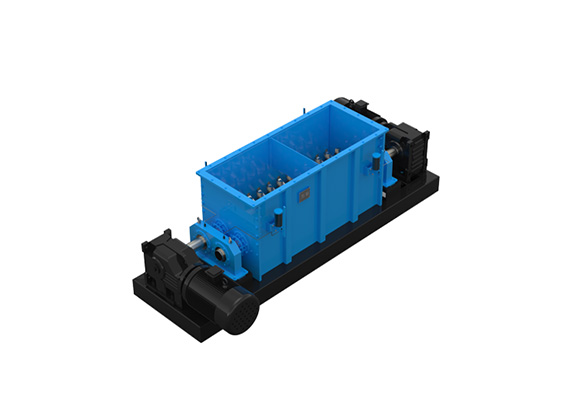

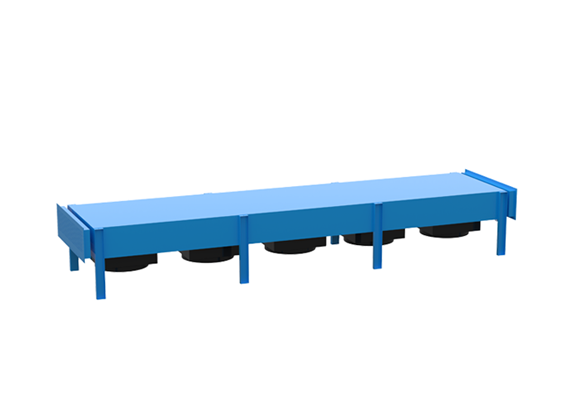

Jiangsu sunrise air cooled condenser is designed for condensing the processing vapours emitted from cooking or drying of fish or meat by-products.

It is a device utilized in refrigeration and air conditioning systems to reject heat to the exterior. It functions as an efficient means of successfully dispersing warmth. It is a device utilized in refrigeration and air conditioning systems to reject heat to the exterior. It functions as an efficient means of successfully dispersing warmth.When cooling space or water availability is limited, air-cooled condensers are the ideal choice. Similarly, these systems are perfect for mobile air con units like those found in vehicles. From industrial applications to home cooling, air cooled condensers offer a practical and efficient solution.

Design characteristics

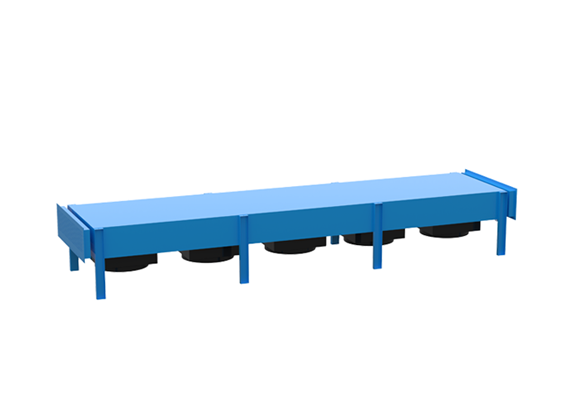

1. Ambient air is blown through the bundle of tubes by a number of fans. Each fan is driven by a directly coupled low-speed electric motor.

2. All parts in contact with vapour, condensate and/or non-condensable gases are manufactured in stainless steel.

3. All other steel parts are hot-dip galvanized steel or aluminium.

4. Large diameter tubes for long intervals between cleaning.

5. Twin pass for best condensate cooling.

6. Options: working platform, non-condensing gas fan.

what is Air Cooled Condenser

To dissipate heat, an air cooled condenser is the go-to type of heat exchanger commonly utilized in both air conditioning and refrigeration systems. This system employs outdoor air to effectively reject temperature away from the unit. In an air cooled condenser, heat is transferred from the system not through water but by using air as the coolant.Get the added benefit of energy efficiency and reduced upkeep with an air-cooled condenser system, plus the peace of mind that it can operate optimally in higher humidity.

Technical parameter

| Model | Capacity (kg/h) | Power/ Motor (kW) | Size(mm) | Weight (kg) |

| HRQ-FL-34 | 2000 | 2*7.5 | 4450*2300*4020 | 3000 |

| HRQ-FL-55 | 3300 | 3*11 | 6400*2300*4080 | 5700 |

| HRQ-FL-72 | 4300 | 4*11 | 8350*2300*4200 | 5700 |

| HRQ-FL-90 | 5400 | 5*11 | 10300*2300*4200 | 7000 |

Hitting temperatures below ambient can be achieved through condensation and cryogenic cooling methods. Reaching over 15°C is easily possible.

Air Cooled Condenser FQA

Dissipating heat is made possible through air cooling in an air-cooled condenser — a type of condenser distinct from those that require water for cooling.An Overview of Frequently Asked Questions Concerning Air-Cooled Condensers:

Q: How does work?

A: It works by passing air over a series of coils or tubes that contain the hot refrigerant. While the air flows over the coils, it takes in the heat from the refrigerant, subsequently lowering its temperature. The refrigerant, now cooled, is then directed back to the compressor, commencing the cycle once more.

Q: What are the advantages ?

A: A significant benefit of employing an air-cooled condenser is its independence from a water source, leading to potential substantial cost savings, especially in regions where water availability poses financial considerations. They are typically easier to install . And more compact than water-cooled condensers.

Q: What are the disadvantages ?

A: A notable drawback associated with employing an air-cooled condenser is its potential lower efficiency when compared to a water-cooled condenser, particularly in extremely hot climates. Furthermore, it might exhibit heightened vulnerability to harm caused by dust, dirt, and various debris, leading to gradual declines in their efficiency over time.

Q: What types of systems ?

A: Air-cooled condensers find prevalent application within systems like air conditioning, refrigeration, and power generation. They also find application in certain industrial processes, including chemical and petrochemical production.