Exploring the Importance of Choosing the Right Rendering Plant Location

Exploring the Importance of Choosing the Right Rendering Plant Location

What does rendering plant mean?

A rendering plant is a facility that turns meat scraps or carcasses into goods that may be used, such as tallow, chicken fat, grease, meat, and bone meal. Rendering facilities play a significant role in the recycling sector and are used to dispose of animal corpses. Animal fats and oils are also processed at rendering facilities for various uses, such as the manufacture of food, soap, and cosmetics. Both the commercial and residential sectors utilize items made from animal products. Lets check the rendering plant location.

What does a rendering plant provide for people?

Rendering plants are establishments that turn animal waste into goods that can be eaten and ones that cannot, such as grease and leather. Removing the fat from animal byproducts is the aim of rendering. Cattle, swine, fowl, and other animals are among the species that are rendered. There are three primary purposes for rendering plants:

- Meat and bone meal production process:

To make meat and bone meal, a rendering facility is used. It is a food processing plant that transforms animal manure into feed, fuel, and other valuable goods like glue and fertilizer. By recycling animal corpses through the rendering process, waste is reduced.

To transform the fat into grease and tallow: Turning fat into tallow and grease occurs at a rendering facility. The straightforward procedure entails melting the fat by heating it with water. After that, a filter separates the liquid from any lingering solid matter from the melted fat. Tallow and grease, two animal fats that may be utilized for creating candles, soap, and other products, are present in the final liquid.

- To create industrial oils and waxes:

Tallow, fat, and grease are converted into industrial oils and waxes at a rendering factory. These materials produce candles, soaps, cosmetics, and other home goods.

The rendering plant location:

Jiangsu SunRise Environmental Protection Technology Co. Ltd, founded in 2016, is a comprehensive environmental technology company devoted to recycling animal protein and fat, kitchen waste treatment, and sludge reduction treatment. The rendering plant location is situated in the lovely city of engineering machinery-Xuzhou. Our firm was rated as a national high-tech enterprise in 2018. It boasts the industry’s most advanced process and technology, 20 senior engineers, 100 senior technicians, and 20,000 square meters of standard industrial facilities.

Our team comprises young individuals with aspirations, inventions, and values. It is 35 years old on average. To significantly expand both local and international markets, we will rely on the unwavering efforts of everyone. We will also continue to maximize consumer value by giving customers access to the best technology, equipment, and artistry. We are a cutting-edge industrial company that combines engineering work, process design, product manufacture, installation training, and technological research and development. For 30 years, Jiangsu Sunrise Eco-protection has concentrated on equipment for the harmless treatment of livestock and poultry, equipment for converting slaughter waste into protein resources, and equipment for melting animal fat.

The future of SunRise:

In this blog post, the rendering plant location in the lovely city of engineering machinery-Xuzhou. Jiangsu Sunrise Environmental Protection Technology Co., Ltd. aspires to be one of the most reputable companies in its field. Jiangsu Sunrise Eco-protection’s mission statement is “the good faith integrity, achievement of customers, improves the self, and the pursuit of excellence.” The company is dedicated to growing with its clients, constantly updating its business idea and development strategy, helping clients achieve the long-term layout in market competition and creating future development blueprints. It also works to build strong customer relationships and become a reputable business.

Properties of the process:

- It is Strong abrupt outbreak reaction capabilities, quick response time, and vast capacity.

- They have thorough sanitation and premium market value for the fat and meat and bone meal products, which are the ultimate products.

- By national vaccination regulatory standards, completely closed manufacturing with minimal secondary environmental contamination.

- It is utilizing PLC technology, easy operation, and labour savings.

- It is high pressure and temperature, full sanitation, and no contact of the substance with steam.

- Automatic processes, closed production, waste gas, and sewage must all be collected, treated, and released after meeting the criteria systematically.

- Low processing costs; no supplementary products required; resource recycling; high value of finished goods.

SERVICE GUARANTEE:

Jiangsu Sunrise Eco-protection offers a service guarantee that it will always provide value for its clients. Jiangsu Sunrise Eco-protection has committed to providing clients with high-quality equipment in conjunction with the necessary technical support and services to enable the smooth integration of the three main service chains before and after the sale. To add more value for customers, our after-sales technical team and quick response plan ensure the smooth operation of all links, including design, production, installation, commissioning, personnel training, and after-sales support. We also offer long-term quality tracking service for turnkey livestock and poultry rendering project that has been tried, tested, and approved.

What is a rendering plant’s process?

After reading the brief explanation above, you should understand what a rendering plant is and how it operates. Cooking raw materials for fertilizer, animal feed, or other products is called rendering. This industrial process transforms a wide range of basic materials into a more usable product. Pet food, fertilizer, and biodiesel manufacturing frequently employ rendered goods. Animal carcasses, usually buried or burned, can be disposed of via the rendering procedure. However, it is most frequently used for animal byproducts, such as bones, blood, hair, hooves, and horns, produced at slaughterhouses and meat packing facilities.

What is the price of a rendering plant machine?

You might be curious about the price of a rendering machine if you’re in the market for one. The cost of a rendering plant machine will vary based on the particular machine and its characteristics, which is the brief response. The machine’s size, capacity, and features are a few things that will impact how much it will cost. Generally speaking, a larger device with greater capacity will cost more than a smaller unit with fewer features. When selecting rendering plant equipment, it’s crucial to consider your demands to avoid overspending on things you won’t utilize.

Conclusion:

The sector of animal protein, oil, nutrition, food, biotechnology, and solid waste treatment is the focus of SunRise, a complete environmental protection technology limited corporation. Our organization has been introducing and assimilating effective management practices, project processing technology, and equipment manufacturing technology to Europe for a century. The deep domestic and international market development, high-quality service delivery, and giving clients the ideal solution.

Categories

Recent Posts

-

What is harmless treatment of sick and dead animals and poultry(rendering plant) A Key Initiative to Protect the Ecological Environment and Food Safety.

March 6, 2025 -

How does Sunrise rendering plant equipment destroy avian influenza viruses in livestock poultry carcasses

March 5, 2025 -

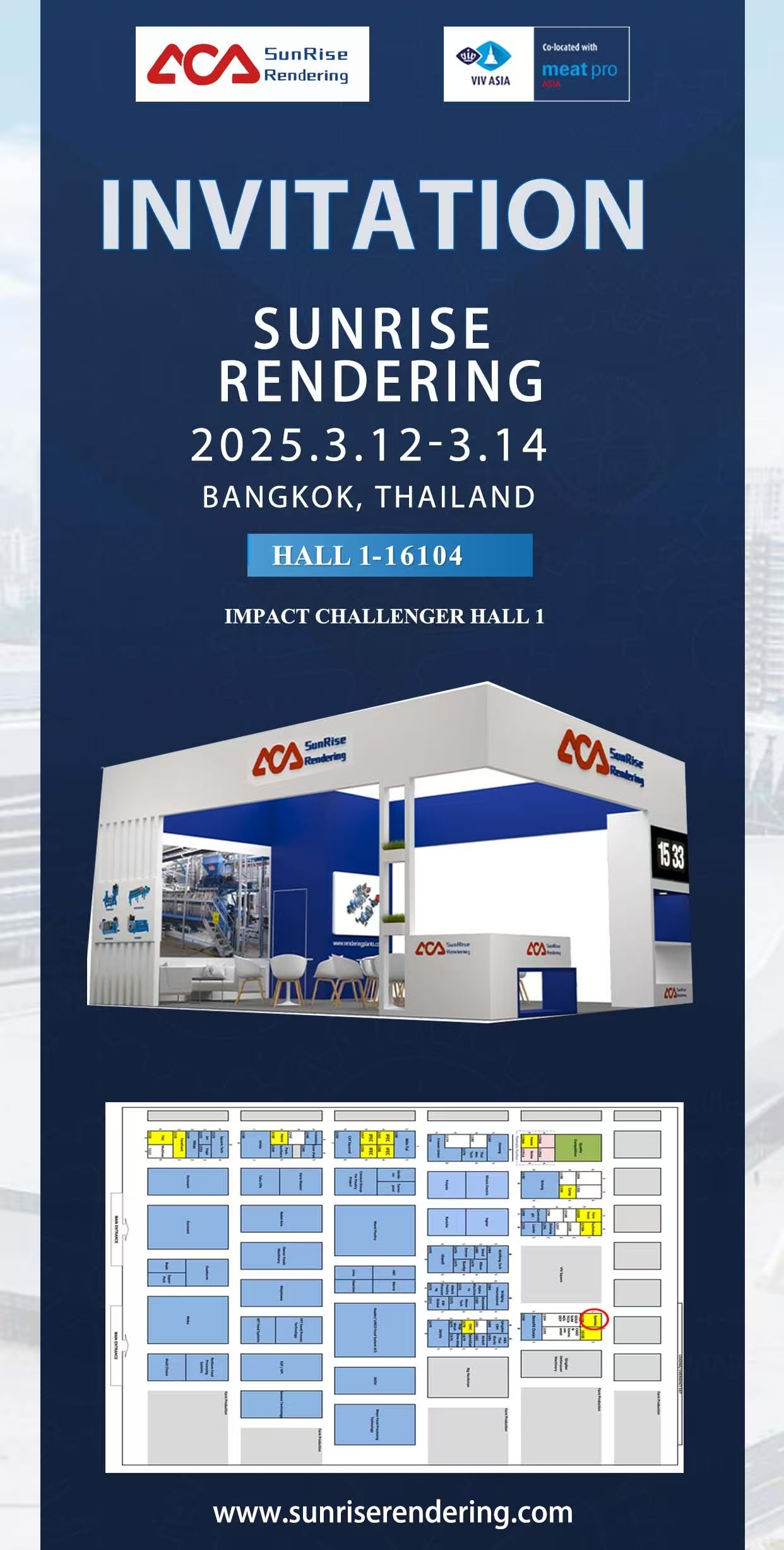

Sunrise Rendering Thailand Exhibition

March 5, 2025