Exploring the Mysteries of the Old Rendering Plant: From Filth to Fascination old rendering plant

Exploring the Mysteries of the Old Rendering Plant: From Filth to Fascination old rendering plant

What is meant by an old rendering plant?

- Ever wonder what mysteries lurk within the walls of an old rendering plant? This long-abandoned institution is in the centre of a tiny town with an eerie past that has long attracted the residents. The history of old rendering factories is surrounded by mystery and intrigue. These industrial sites, formerly connected to questionable operations and a dismal background, have seen dramatic changes recently.

- An abandoned rendering factory is one such location that attracts the interest of many adventurers and urban explorers because of its attraction. It is like entering a time machine that returns us to a long-forgotten past.

- Urban explorers and history buffs alike have long been intrigued by this abandoned industrial site’s abandoned walls and spooky atmosphere.

The Unexpected Benefits of an Old Rendering Plant

Reusing ancient rendering plants has drawn much attention in today’s culture, where environmental responsibility and sustainability are top priorities. Previously only used to treat animal byproducts for diverse purposes, these facilities are now being turned into cutting-edge, environmentally friendly businesses.

- In today’s world, where sustainability and eco-consciousness have become paramount, repurposing old industrial buildings is a trend that benefits the environment and holds significant economic potential. One such remarkable example is the transformation of an old rendering plant. These facilities play a crucial role in the recycling and repurposing animal by-products, transforming them into valuable resources.

- Rendering plants illustrate the proverb, “One man’s trash is another man’s treasure.” Even though these establishments may be glitzy or well-known, they are essential in converting garbage into useful resources.

Industries are continually looking for creative methods to adapt outdated facilities and lessen their environmental effect in the ever-evolving field of sustainability and waste management. The rendering sector has lately attracted interest, and one approach is to reuse old rendering plant.

Knowledge of the Rendering Process

The rendering process involves turning useful items like protein meals, fats, and oils from animal byproducts, including carcasses, bones, and offal. These leftovers are gathered from butcher shops, slaughterhouses, and other food processing facilities. The following steps are commonly included in the rendering process:

- Collection and delivery:

Animal byproducts are safely and hygienically collected and delivered to rendering factories.

- Grinding and cooking:

The byproducts are crushed into tiny bits and heated at high temperatures to eliminate any microorganisms, eliminate moisture, and separate the lipids from the proteins.

- Pressing and separation:

Following cooking, the ingredients are pressed to separate the meal’s solid protein from the liquid fat or oil.

- Drying and refining:

After separating the components, they are dried and processed to create the final products, which include protein meals, fats, and oils.

- Packaging:

The producer packs the finished goods in various bags or containers depending on who they are intended for.

Sunrise Rendering Facilities: A New Dawn in Rendering

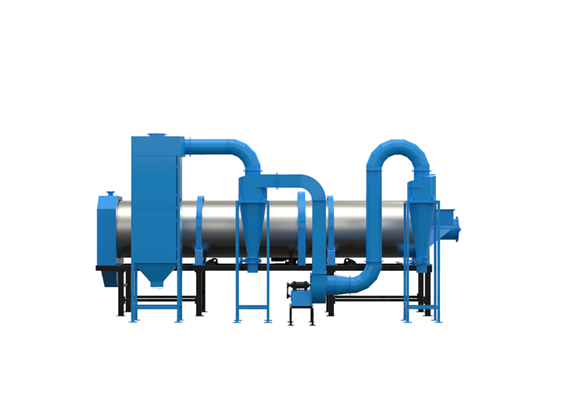

A key component of the world economy is the Sunrise Rendering sector. It is essential to process animal byproducts since it turns them into useful commodities, including protein meals, fats, and oils. These final products are used in various industries, such as agriculture, pet food, and biodiesel manufacturing. As effective and sustainable waste management solutions rise, the need for cutting-edge rendering technology is greater than ever. Let me introduce you to the Sunrise Rendering Plant Machine, a ground-breaking system that aims to reinvent rendering facilities and revolutionize the sector.

Facilities for Sunrise Rendering: High-Quality and High-Performance

A group of specialists created the Sunrise Rendering Plant Machine with years of expertise in the rendering sector. It is intended to maximize efficiency, lessen environmental effects, and reduce operating expenses. This cutting-edge machine was constructed using cutting-edge technology, making it one of the most sophisticated rendering options. Some of the main characteristics and advantages of the Sunrise Rendering Plant Machine are listed below:

- Improved productivity and efficiency

The Sunrise Rendering Plant Machine has high-performance parts that enable it to handle a lot of raw materials in a short amount of time. By boosting production capacity via enhanced efficiency, rendering facilities can better fulfil the rising demand for their goods. The machine’s automated mechanism also lessens the need for physical labour, which lowers operating expenses.

- Second-generation Odour Control System

The release of offensive odours from rendering operations is one of the key issues. This problem is addressed by the Sunrise Rendering Plant Machine, which features cutting-edge odour control technology. This technology efficiently eliminates odours, ensuring that the facility’s activities have no detrimental effects on the neighbourhood.

- Energy Savings

Energy conservation was a priority in the design of the Sunrise Rendering Plant Machine. Its state-of-the-art heat recovery technology recycles the heat produced during rendering, drastically lowering energy usage. This function makes the machine an ecologically beneficial option for rendering plants by reducing operational expenses and carbon emissions.

- Enhanced Goods Quality

The sophisticated technology of the Sunrise Rendering Plant Machine guarantees a consistently high-quality final output. The machine reduces the chance of contamination and ensures that the protein meals, fats, and oils produced are up to the highest industry requirements by precisely controlling temperature and pressure during the rendering process.

- Scalability and low maintenance

The Sunrise Rendering Plant Machine has easily accessible parts and a modular design that makes it simple to expand as a facility’s needs change. With the help of this function, rendering facilities may adjust to fluctuations in demand without suffering lengthy outages or exorbitant renovations.

Conclusion:

The Sunrise Rendering Plant Machine represents a new era in rendering technology. This cutting-edge device is poised to revolutionize rendering operations worldwide thanks to its increased efficiency, eco-friendly features, and dedication to delivering high-quality final products. The SunRise Rendering Plant Machine will undoubtedly be crucial in determining how the industry develops, ultimately leading to a more effective and sustainable waste management solution for our world.

Categories

Recent Posts

-

What is harmless treatment of sick and dead animals and poultry(rendering plant) A Key Initiative to Protect the Ecological Environment and Food Safety.

March 6, 2025 -

How does Sunrise rendering plant equipment destroy avian influenza viruses in livestock poultry carcasses

March 5, 2025 -

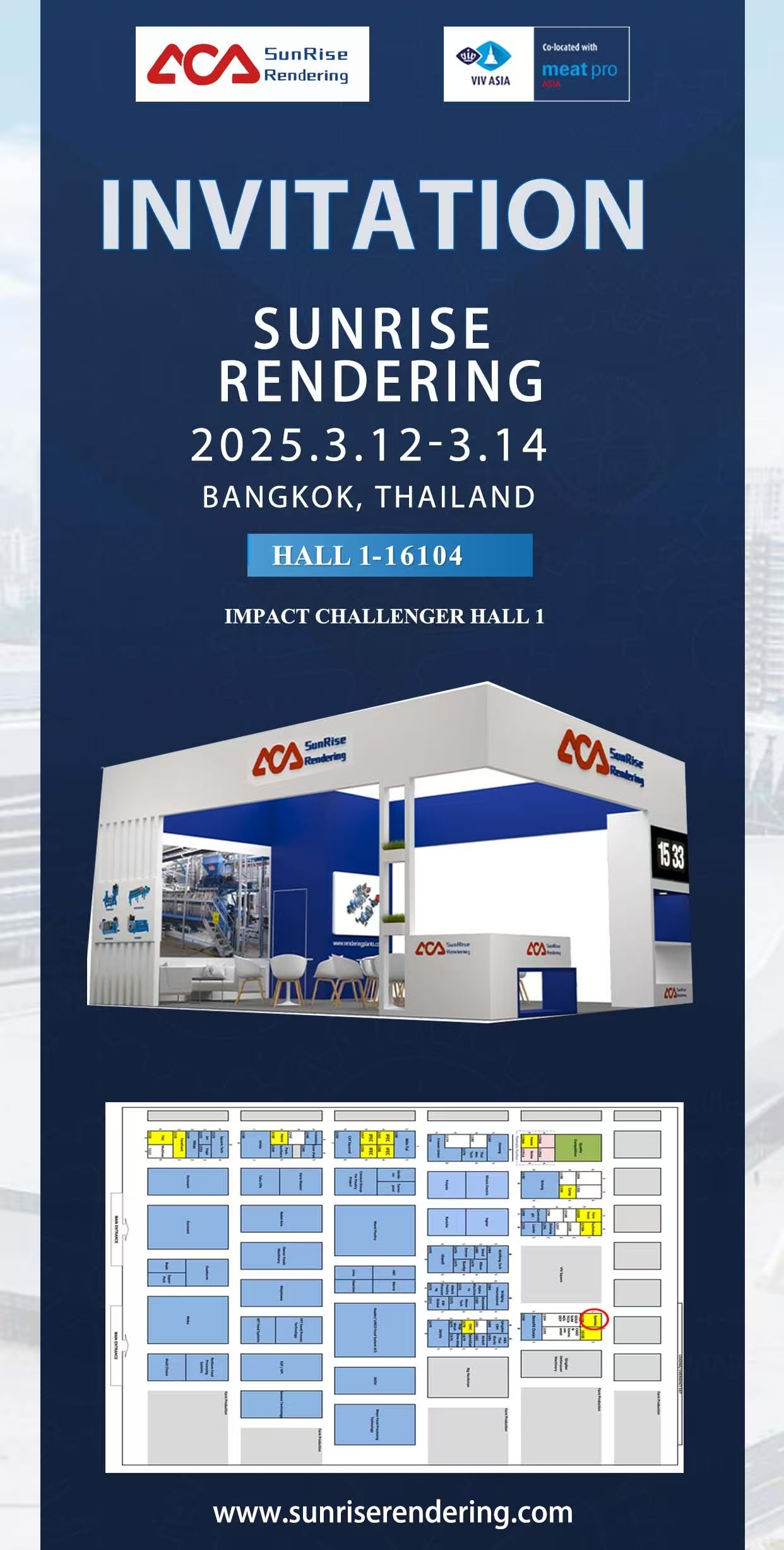

Sunrise Rendering Thailand Exhibition

March 5, 2025