Fat Press: What It Is and How It Works

Fat Press: What It Is and How It Works

Fat press is an innovative technology that has been gaining popularity in the food industry in recent years. It is a process that involves applying high pressure to food products to extract oil or fat from them. This technique is gaining attention as a healthier alternative to traditional oil extraction methods, which often involve the use of chemicals or high heat.

One of the main benefits of fat press is that it results in a product that is free from harmful chemicals and solvents. This makes it an attractive option for health-conscious consumers who are looking for natural and minimally processed foods. Additionally, meat bone fat press can be used to extract oil from a variety of sources, including nuts, seeds, and even fruits like avocados, making it a versatile technology that can be used in a range of applications.

As the demand for healthier and more sustainable food options continues to grow, it is likely that fat press will become an increasingly important technology in the food industry. In the following article, we will explore the science behind fat press, its benefits and limitations, and some of the most promising applications of this innovative technology.

Overview of Fat Press Technology

Historical Development

Fat press technology has been in use for centuries. The earliest known use of a fat press dates back to ancient Greece, where olive oil was extracted using a type of press. Over time, the technology evolved and was used to extract fats from various sources, including animal fats and vegetable oils.

In the 19th century, the invention of the hydraulic press revolutionized fat pressing. This press used hydraulic pressure to extract oils and fats from seeds and nuts. The process was faster and more efficient than previous methods.

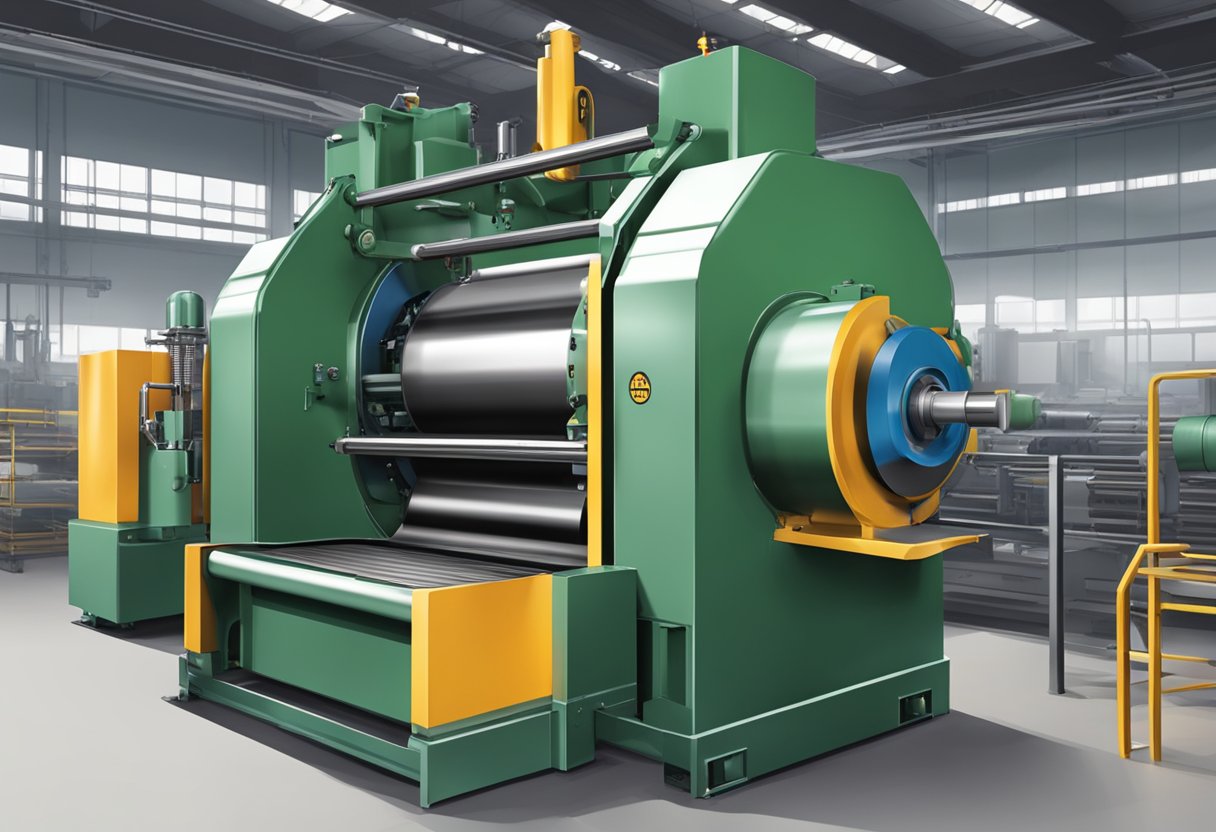

Types of Fat Press Machines

Today, there are several types of fat press machines available on the market. Some of the most common types include:

- Screw press: This type of press uses a screw to compress the material and extract the oil or fat.

- Hydraulic press: This press uses hydraulic pressure to extract oil or fat from the material.

- Expeller press: This press uses a mechanical process to extract oil or fat from seeds and nuts.

- Centrifugal press: This press uses centrifugal force to separate oil or fat from the material.

Each type of machine has its own advantages and disadvantages, and the choice of machine will depend on the specific application and desired outcome.

Overall, fat press technology has come a long way since its early beginnings. Today, it is a vital part of many industries, including food production, cosmetics, and pharmaceuticals. With continued technological advancements, it is likely that fat press machines will become even more efficient and effective in the years to come.

Mechanics of Fat Extraction

Pressing Techniques

Fat extraction involves the separation of fat from other components of a food product. Pressing is one of the most common techniques used for fat extraction. The process involves applying pressure to the food product to squeeze out the fat. The type of press used and the amount of pressure applied can affect the quality and quantity of the extracted fat.

There are two main types of presses used for fat extraction: hydraulic presses and screw presses. Hydraulic presses use a hydraulic cylinder to apply pressure to the food product, while screw presses use a rotating screw to apply pressure. Both types of presses have their advantages and disadvantages, and the choice of press depends on the specific application.

Yield Optimization

Maximizing the yield of extracted fat is important for economic and environmental reasons. Yield optimization involves adjusting the pressing parameters to achieve the highest possible yield of fat without compromising the quality of the extracted fat.

Factors that affect yield include the type of press used, the pressure applied, the temperature of the food product, and the duration of the pressing process. It is important to carefully control these parameters to achieve optimal yield.

In addition to pressing techniques, other methods such as solvent extraction and centrifugation can also be used for fat extraction. However, pressing remains a popular and effective method for fat extraction due to its simplicity and cost-effectiveness.

Applications of Fat Pressing

Food Industry

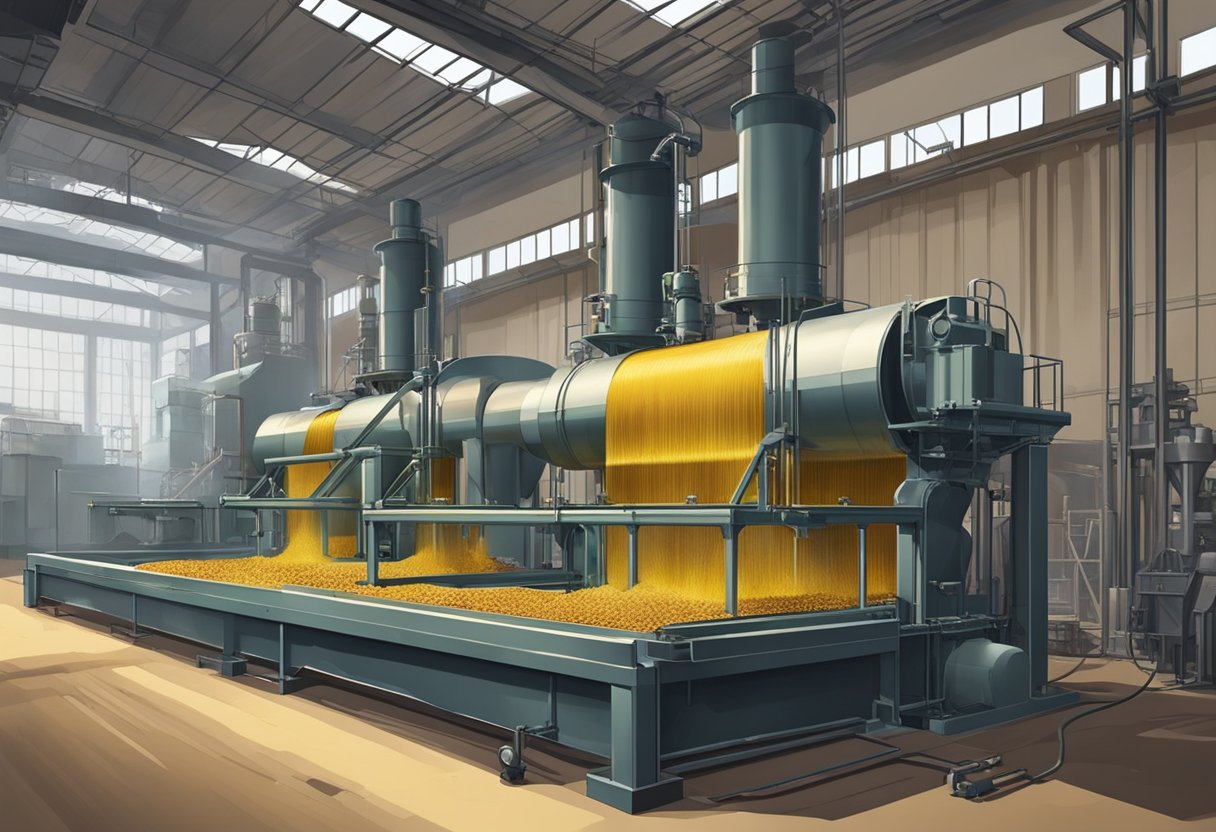

Fat pressing is a widely used process in the food industry. It is used to extract oil from various types of seeds, nuts, and fruits. The extracted oil can be used for cooking, baking, frying, and salad dressing. The process of fat pressing involves crushing the seeds, nuts, or fruits to release the oil, and then using a press to extract the oil from the crushed material.

One of the most common applications of fat pressing in the food industry is in the production of vegetable oils. Vegetable oils are used in a wide range of food products, including margarine, mayonnaise, and salad dressings. Fat pressing is also used to produce nut oils, such as almond oil and walnut oil, which are used in baking and cooking.

Cosmetics Production

Fat pressing is also used in the production of cosmetics. It is used to extract oils from various plants, such as jojoba, coconut, and avocado, which are used in skincare and hair care products. The extracted oils are rich in vitamins and minerals that are beneficial for the skin and hair.

The process of fat pressing is also used to extract essential oils from plants, such as lavender, peppermint, and eucalyptus. Essential oils are used in a wide range of cosmetic products, including perfumes, lotions, and shampoos.

In conclusion, fat pressing is a versatile process that has many applications in the food industry and cosmetics production. It is a cost-effective and efficient way to extract oils from various types of seeds, nuts, and fruits, and is widely used in the production of vegetable oils, nut oils, and essential oils.

Materials Processed with Fat Press

Seed Oils

Fat press is a machine that is used to extract oil from various materials. One of the most common materials processed with fat press is seed oils. Seed oils are extracted from the seeds of plants such as sunflower, soybean, rapeseed, and cottonseed. These oils are commonly used for cooking, baking, and frying due to their high smoke point and neutral flavor.

The fat press is an efficient machine for extracting seed oils. The seeds are first cleaned and then crushed to release the oil. The crushed seeds are then fed into the fat press, which uses pressure to extract the oil from the seeds. The oil is then collected in a container and can be further refined to remove impurities.

Animal Fats

Another material that can be processed with fat press is animal fats. Animal fats are extracted from the tissues of animals such as cows, pigs, and chickens. These fats are commonly used in the food industry for frying, baking, and as an ingredient in various products such as margarine and shortening.

Fat press is an efficient machine for extracting animal fats. The animal tissues are first cleaned and then heated to melt the fat. The melted fat is then fed into the fat press, which uses pressure to extract the fat from the tissues. The fat is then collected in a container and can be further refined to remove impurities.

In conclusion, fat press is a versatile machine that can be used to extract oil from various materials such as seed oils and animal fats. It is an efficient and cost-effective method of extracting oil and is commonly used in the food industry.

Operational Parameters

Temperature Control

In order to achieve optimal results during the fat pressing process, temperature control is a critical operational parameter. The temperature of the fat should be maintained within a specific range to ensure that the fat is properly melted and that the desired texture and consistency is achieved. Typically, the temperature range for fat pressing is between 35°C and 45°C.

It is important to note that the temperature control should be monitored and adjusted as needed throughout the fat pressing process. This can be done using a thermometer or other temperature measuring device. Additionally, it is important to ensure that the temperature is consistent throughout the entire fat pressing process to ensure uniform results.

Pressure Settings

Another critical operational parameter for fat pressing is pressure settings. The pressure applied during the pressing process can have a significant impact on the final product. The pressure should be set to a level that is appropriate for the type of fat being pressed and the desired outcome.

Typically, the pressure range for fat pressing is between 300 and 500 psi. However, this can vary depending on the type of fat being pressed and the desired outcome. It is important to monitor the pressure throughout the pressing process and adjust as needed to ensure consistent results.

Overall, careful attention to operational parameters such as temperature control and pressure settings is essential for achieving high-quality results during the fat pressing process. By monitoring and adjusting these parameters as needed, operators can ensure that the final product meets the desired specifications and is of the highest quality.

Safety and Maintenance

Routine Checkups

Regular maintenance and checkups are essential to ensure the safety and longevity of your fat press. It is recommended to perform routine inspections every six months or after every 500 hours of use, whichever comes first. During these checkups, the following components should be inspected:

- Hydraulic system: Check for any leaks, cracks, or damage to the hoses, fittings, and seals. Replace any damaged components immediately.

- Electrical system: Inspect all electrical connections, wires, and switches for damage or wear. Replace any damaged components and tighten any loose connections.

- Frame and structure: Check for any cracks, dents, or signs of wear on the frame and structure of the press. If any damage is found, contact a qualified technician for repair.

- Lubrication: Ensure that all moving parts are properly lubricated to prevent excessive wear and tear.

Emergency Protocols

In the event of an emergency, it is important to follow proper safety protocols to avoid injury or damage to the press. The following steps should be taken in case of an emergency:

- Shut off the power: Turn off the power to the press immediately to prevent any further damage or injury.

- Assess the situation: Determine the cause of the emergency and assess the extent of the damage.

- Contact a qualified technician: If the damage is severe or if there is any risk of injury, contact a qualified technician for assistance.

- Document the incident: Take photos and notes of the incident for insurance and liability purposes.

By following these safety and maintenance guidelines, you can ensure the safe and efficient operation of your fat press for years to come.

Regulatory Compliance

Health and Safety Standards

Fat press manufacturers must comply with various health and safety standards to ensure the safety of their workers and consumers. These standards include regulations set by the Occupational Safety and Health Administration (OSHA), such as proper machine guarding, lockout/tagout procedures, and personal protective equipment (PPE). It is important for manufacturers to implement these standards to prevent injuries and accidents in the workplace.

In addition to OSHA standards, manufacturers must also comply with food safety regulations set by the Food and Drug Administration (FDA). These regulations include proper sanitation, labeling, and packaging of food products. Failure to comply with these regulations can result in fines and legal action.

Environmental Regulations

Fat press manufacturers must also comply with various environmental regulations to reduce their impact on the environment. These regulations include the Clean Air Act, Clean Water Act, and Resource Conservation and Recovery Act (RCRA). Manufacturers must ensure that their operations do not release harmful pollutants into the air or water, and that they properly dispose of any hazardous waste generated during production.

To comply with these regulations, manufacturers can implement various measures such as installing pollution control equipment, using environmentally friendly materials, and properly disposing of waste. It is important for manufacturers to take these regulations seriously to minimize their impact on the environment and avoid legal consequences.

Overall, regulatory compliance is crucial for fat press manufacturers to ensure the safety of their workers, consumers, and the environment. By implementing proper health and safety and environmental standards, manufacturers can operate responsibly and avoid legal and financial consequences.

Market Trends and Forecasts

Consumer Demand

The demand for fat press is on the rise due to the increasing health consciousness among consumers. People are becoming more aware of the benefits of consuming healthy oil and are switching to fat press for their cooking needs. The market for fat press is expected to grow significantly in the coming years.

According to market research, the global fat press market was valued at USD 1.2 billion in 2020 and is expected to reach USD 1.8 billion by 2025, growing at a CAGR of 8.1% during the forecast period. The increasing popularity of fat press among consumers is one of the major factors driving the growth of the market.

Technological Advancements

The fat press industry is witnessing a significant transformation due to technological advancements. Manufacturers are investing in research and development to improve the efficiency and quality of their products. This has led to the development of advanced fat press machines that are more efficient and produce higher quality oil.

The use of automation and artificial intelligence in the fat press industry is also gaining traction. These technologies are being used to optimize the production process, reduce wastage, and improve the quality of the oil produced. The incorporation of these technologies is expected to drive the growth of the fat press market in the coming years.

In conclusion, the fat press market is expected to grow significantly in the coming years due to the increasing demand for healthy oil and technological advancements in the industry. Manufacturers are investing in research and development to improve the efficiency and quality of their products, which is expected to drive the growth of the market.

Challenges in Fat Pressing

Fat pressing is an essential process in the production of various food products, including butter, margarine, and oils. However, the process is not without its challenges. This section explores some of the common challenges encountered in fat pressing.

Contamination Risks

One of the significant challenges in fat pressing is contamination. During the process, the fat comes into contact with various surfaces, including the equipment and the environment. If the surfaces are not properly cleaned and sanitized, they can contaminate the fat, leading to spoilage, off-flavors, and even foodborne illnesses.

To mitigate contamination risks, it is crucial to ensure that all equipment and surfaces that come into contact with the fat are properly cleaned and sanitized. Regular testing of the fat for microbial and chemical contamination is also essential to ensure that it meets the required safety and quality standards.

Equipment Wear and Tear

Another challenge in fat pressing is equipment wear and tear. The high-pressure and high-temperature conditions in the press can cause damage to the equipment over time, leading to leaks, malfunctions, and even breakdowns. This can result in production delays, increased costs, and reduced product quality.

To address equipment wear and tear, it is essential to ensure that the equipment is properly maintained and serviced. Regular inspections, cleaning, and lubrication can help prevent damage and prolong the lifespan of the equipment. It is also crucial to replace worn-out parts and components promptly to avoid costly breakdowns and production delays.

In conclusion, fat pressing is a crucial process in the production of various food products. However, it is not without its challenges, including contamination risks and equipment wear and tear. By implementing proper cleaning, sanitation, maintenance, and servicing practices, these challenges can be mitigated, ensuring safe, high-quality, and cost-effective fat pressing operations.

Future of Fat Pressing

Innovations and Research

As technology advances, the future of fat pressing looks promising. Innovations in the industry are focused on improving the efficiency and effectiveness of the process. One such innovation is the development of automated fat pressing machines that can handle large quantities of fat with minimal human intervention. These machines have increased the speed of production and reduced the amount of waste generated during the process.

Research is also being conducted to explore the use of alternative materials for pressing fat. This includes the use of plant-based materials that can mimic the texture and taste of animal fat. Such alternatives could potentially reduce the environmental impact of the industry and cater to the growing demand for sustainable food options.

Sustainability Initiatives

The fat pressing industry has also been implementing sustainability initiatives to reduce its impact on the environment. This includes the use of renewable energy sources such as solar and wind power to power the machines. Additionally, efforts are being made to reduce waste generated during the process by implementing recycling programs and using biodegradable materials.

Some companies are also exploring the use of regenerative agriculture practices to produce the raw materials used in fat pressing. This involves using farming techniques that promote soil health and biodiversity, leading to a more sustainable and resilient food system.

Overall, the future of fat pressing looks bright with a focus on innovation and sustainability. As the industry continues to evolve, it will be interesting to see how these advancements will shape the way we produce and consume food.

Categories

Recent Posts

-

Slaughter waste – what can feathers do – animal protein conversion

May 13, 2025 -

SUNRISE makes another appearance at the Saudi Poultry Expo (MEP) using Chinese intelligent manufacturing to support Saudi Arabia’s 2030 green vision

April 19, 2025 -

The Challenges of Poultry Rendering in the Philippines Market

April 12, 2025