Sustainable Solutions for Poultry Waste: Feather Meal Continuous Hydrolyzer

Sustainable Solutions for Poultry Waste: Feather Meal Continuous Hydrolyzer

In the pursuit of a more sustainable future, innovative technologies and solutions are crucial to address pressing environmental challenges. Poultry waste, particularly feathers, has long been a significant concern due to its vast quantities and limited disposal options. However, a breakthrough product has emerged to tackle this issue head-on – the Feather Meal Continuous Hydrolyzer developed by SunRise, a leading manufacturer of sustainable solutions.

The SunRise Feather Meal Continuous Hydrolyzer represents a cutting-edge advancement in the processing of feathers, hog hair, and animal offal. Designed with the utmost efficiency and ease of operation in mind, this equipment offers a sustainable and practical solution to transform poultry waste into valuable feather meals.

What’s Feather Meal Continuous Hydrolyzer?

The Feather Meal Continuous Hydrolyzer is a game-changing equipment designed to optimize the processing of feathers, hog hair, and animal offal. Unlike traditional batch cookers, this innovative hydrolyzer employs a continuous processing approach, resulting in improved efficiency and output.

1. Efficiency at its Core:

One of the standout features of the Feather Meal Continuous Hydrolyzer is its remarkable efficiency. By utilizing a continuous processing method, the hydrolyzer eliminates the need for frequent start-stop cycles associated with batch cooking. This uninterrupted process significantly reduces downtime, thereby enhancing overall productivity.

2. Streamlined Operation:

SunRise has prioritized user-friendly design in the Feather Meal Continuous Hydrolyzer. With its intuitive interface and automated controls, operating the hydrolyzer becomes a seamless task. The equipment incorporates advanced computerized systems that monitor and regulate various parameters, ensuring precise and consistent results. This streamlines the entire production process and allows operators to focus on other critical tasks.

3. Enhanced Product Quality:

The continuous hydrolysis process employed by this innovative equipment leads to improved product quality. Feather meal, hog hair, and animal offal undergo thorough and consistent cooking, resulting in better texture, taste, and nutritional value. The precise control over processing conditions helps to eliminate undercooked or overcooked batches, enhancing the overall quality of the end product.

How Does Feather Meal Continuous Hydrolyzer Work?

Feather meal, a byproduct of the poultry industry, has gained recognition as an excellent source of protein in animal feed. The process of converting feathers into valuable protein involves a complex method known as hydrolysis. Among the innovative technologies revolutionizing this process is the Feather Meal Continuous Hydrolyzer, developed by the renowned manufacturer, SunRise.

1. The Reactor

At the heart of the Feather Meal Continuous Hydrolyzer lies the reactor, a vessel specially designed to facilitate the hydrolysis process. Feathers, usually in their raw form, are loaded into the reactor through an inlet. The reactor provides an environment conducive to the breakdown of complex proteins into smaller, more digestible peptides and amino acids. Maintaining precise temperature and pressure conditions within the reactor is vital to ensure efficient hydrolysis.

2. Heat Exchanger

To achieve optimal hydrolysis, the Feather Meal Continuous Hydrolyzer employs a heat exchanger. This component transfers thermal energy from the effluent to the incoming raw material, promoting energy efficiency within the system. By preheating the raw material before it enters the reactor, the heat exchanger enhances the hydrolysis process and reduces the overall energy requirements of the system.

3. Steam System

The supply of steam is critical to maintaining the desired temperature within the reactor. SunRise’s Feather Meal Continuous Hydrolyzer incorporates a sophisticated steam system that ensures a constant and precise flow of steam. By regulating the steam supply, the hydrolysis process can be fine-tuned to achieve optimal conversion of feathers into valuable proteins.

4. Mixing and Agitation Mechanism

To ensure uniform distribution of heat and reactants, the Feather Meal Continuous Hydrolyzer is equipped with a robust mixing and agitation mechanism. This mechanism aids in breaking down feathers and facilitates the even distribution of heat throughout the reactor. Through controlled mixing, it promotes maximum exposure of feathers to the hydrolysis environment, ensuring thorough protein breakdown.

5. Separation and Filtration

Once the hydrolysis process is complete, the Feather Meal Hydrolyzer employs an efficient separation and filtration system to extract the desired feather meal from the hydrolysate. This system uses a combination of techniques such as centrifugation, sedimentation, and filtration to remove any remaining solids and impurities from the protein-rich solution. The separated feather meal can then be further processed or utilized as a valuable ingredient in animal feed.

Revolutionize Your Production Process: The Continuous Automated Operation of Feather Meal Continuous Hydrolyzer

One of the primary advantages of the Feather Meal Hydrolyzer is its continuous automated operation. By eliminating the need for batch cooking and adopting a continuous processing approach, this equipment streamlines the entire production process, resulting in higher productivity and reduced energy consumption.

The hydrolyzer’s unique design characteristics contribute to its exceptional performance. The special main shaft ensures efficient and uniform hydrolyzation, guaranteeing high-quality feather meal output consistently. Additionally, safeguards against plug feed loss minimize interruptions and enhance operational reliability. With only one pressurized stuffing box to maintain, maintenance requirements are simplified, further enhancing the overall user experience.

SunRise understands the importance of versatility in meeting diverse industry needs. Consequently, the continuous hydrolyzer can be manufactured in stainless steel, carbon steel, or a combination of both, providing flexibility to tailor the equipment to specific operational requirements. This adaptability allows for seamless integration into existing production facilities.

Minimize Environmental Impact: Feather Meal Continuous Hydrolyzer Maximizes Resource Efficiency

The Feather Meal Continuous Hydrolyzer is a solution designed with sustainability at its core. It operates with low steam consumption, consuming a mere 0.71 pounds of raw material feather per kilogram. By maximizing resource efficiency, this equipment minimizes waste and reduces environmental impact.

The target audience that stands to benefit the most from this revolutionary product includes poultry farmers, food processing plants, and large-scale food production facilities. These stakeholders often struggle with the vast amounts of poultry waste generated during their operations. Disposal of feathers has traditionally been a challenge, as they are difficult to break down and can contribute to pollution if not managed properly.

By adopting the Feather Meal Hydrolyzer, these entities can effectively convert poultry waste into a valuable resource. The hydrolyzer solves the problem of waste accumulation while simultaneously generating feather meal, a nutrient-rich product that can be used as a high-protein feed additive. This solution not only addresses the waste management issue but also provides an economic advantage by creating a marketable byproduct.

Moreover, the continuous hydrolyzer ensures the sustainable use of resources and complies with national standards, meeting regulatory requirements while optimizing operational efficiency. By investing in this advanced technology, the target audience can enhance their environmental credentials, reduce waste disposal costs, and capitalize on the potential for additional revenue streams.

Conclusion

SunRise’s Feather Meal Continuous Hydrolyzer represents a breakthrough in sustainable solutions for poultry waste. Its innovative design, automated operation, and resource efficiency make it an ideal choice for poultry farmers, food processing plants, and large-scale food production facilities. By addressing the challenges of waste accumulation and transforming feathers into valuable feather meals, this equipment not only benefits the environment but also provides economic opportunities for its users. SunRise’s commitment to sustainability and excellence shines through this remarkable product, paving the way for a more sustainable and responsible poultry industry.

Categories

Recent Posts

-

What is harmless treatment of sick and dead animals and poultry(rendering plant) A Key Initiative to Protect the Ecological Environment and Food Safety.

March 6, 2025 -

How does Sunrise rendering plant equipment destroy avian influenza viruses in livestock poultry carcasses

March 5, 2025 -

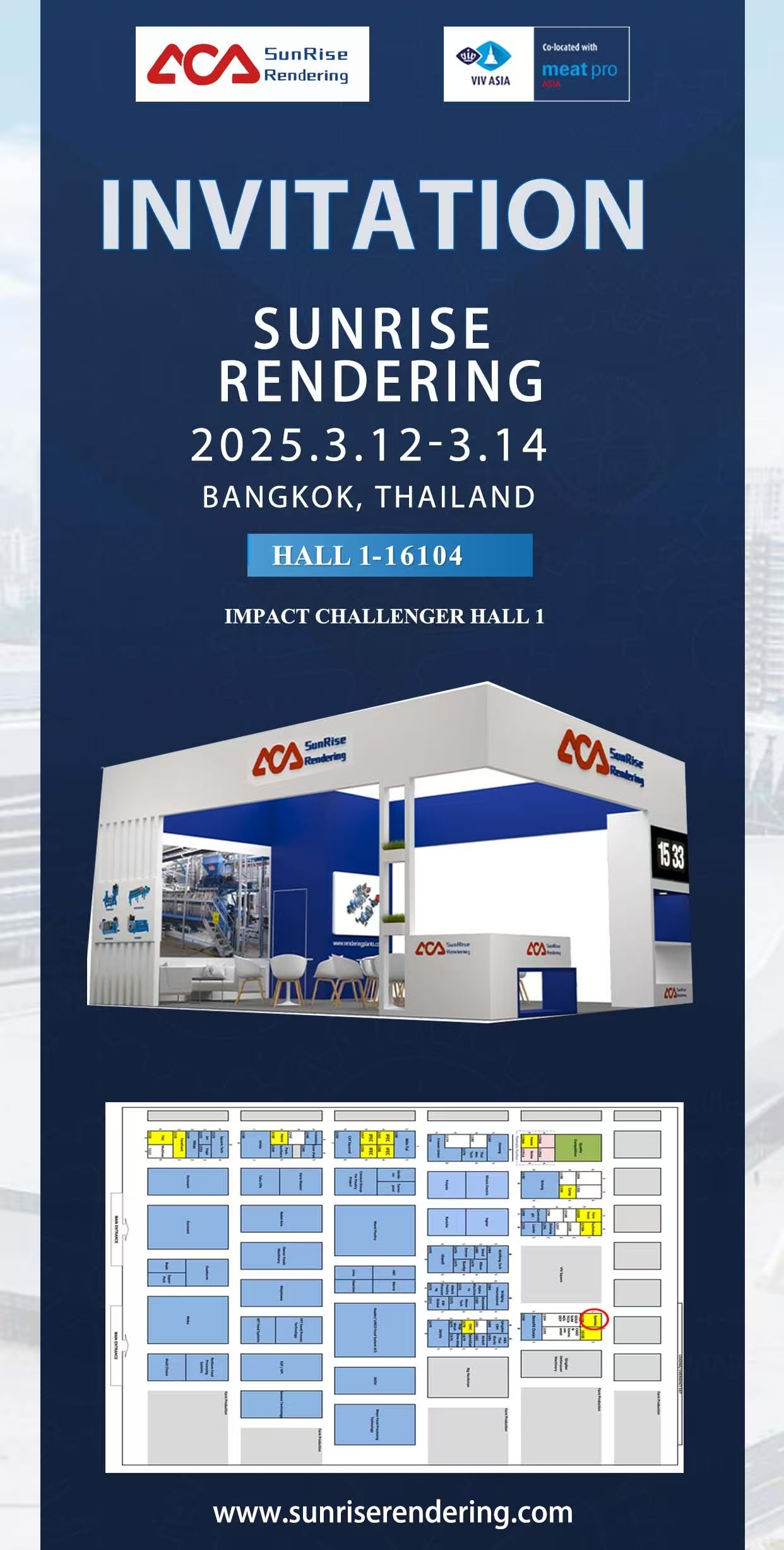

Sunrise Rendering Thailand Exhibition

March 5, 2025