How Does The Lamella Pump Work?

How Does The Lamella Pump Work?

The working principle of how does the lamella pump work

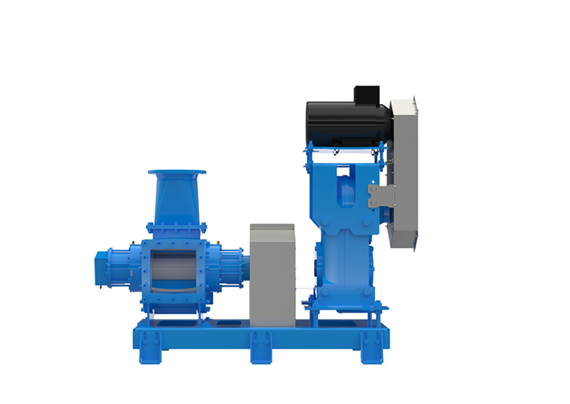

So how does the lamella pump work, its work is very simple, taking the Sunrise Lamella Pump as an example, it consists of a rotor and stator which are rotatable about the same axis.

The stator has porous walls and holes in them for allowing fluid to pass through the rotor and enter into its central cavity where it gets compressed by centrifugal force and emerges from discharge ports on the periphery of the rotor as required output pressure and flow rate.

When the holes are closed, no raw material will flow out of them. When the holes are opened, the material will flow out from them. The working principle of lamella pumps can be divided into three stages: preloading stage, rotation stage, and discharging stage.

1. Preloading Stage

During the preloading stage, the liquid is loaded into the pump chamber by the centrifugal force generated by the impeller rotation speed difference of how does the lamella pump work between the impeller and casing wall before the actual pumping process starts. The material enters the suction port of the pump through its suction pipe and flows into the inlet chamber of the lamella blade.

2. Rotation Stage

During the rotation stage, the impeller begins to rotate at high speed while the casing wall remains stationary due to its larger radius than the impeller radius. This generates high pressure at the outlet end while low pressure at the suction end.

The speed of movement of these plates can be varied, thereby controlling the amount of material that is pumped out per unit of time. It then passes through the central channel of the lamella blade, which is formed by the concave surface of the blade and the convex surface of the casing.

3. Discharging Stage

When the pre-broken animal by-products enter into the outlet chamber of the lamella blade, it flows up along with the lamella blade rising up because of centrifugal force and leaves through the outlet port by centrifugal force when the lamella blade drops down again after reaching the top dead center position.

Therefore, the liquid is pushed out through the discharge port while maintaining constant volume inside the pump chamber. Meanwhile, this process also contributes to increasing impeller rotational speed because of its larger radius than the casing.

What are the types of lamella pumps?

After a brief understanding of how does the lamella pump work, you should also know the types of lamella pump. There are three types of lamella pumps: Positive Displacement Pump, Centrifugal Pump, and Rotary Pump.

Positive displacement Pumps

These pumps have a fixed displacement volume, which means that the volume will be pumped out in each stroke. The positive displacement pump uses pistons to drive fluid through its moving parts.

Centrifugal Pumps

These pumps are suitable for using centrifugal force to move fluid through them. They use centrifugal impellers to achieve high pressure and velocity flow rates. The centrifugal force pushes the liquid outwards against the inside wall of the vortex chamber, thereby increasing pressure in the process.

Rotary Pumps

Rotary pumps are used for pumping highly viscous liquids like heavy oil, tar or bitumen, etc. Where conventional mechanical pumps fail. Cavity pumps work on the principle of “vortex motion” where fluid moves in a rotary motion inside a hollow rotor tube.

The rotation of the drum creates a centrifugal force that forces the liquid out of one chamber, through the inlet valve, and into the other chamber where it flows back into the drum via an outlet valve. This type of pump is typically used with liquids that have high viscosity and solids content.

How powerful is the lamella pump?

In a rendering plant, the most common use of a lamella pump system of how does the lamella pump work such as screw conveyors is to pump the tallow from the tank to the cooker and then from there to the kettle where it will be cooked.

The main advantage of this kind of pump is that it can use conveyor belts to handle very viscous and pasty material. This type of pump has a unique design that allows it to handle high viscosities without clogging.

It is also very efficient at pumping large particles like bone tissues which makes it ideal for handling fats and oils. In fact, it has been used in many industries including food processing plants and breweries because of its ability to handle liquids with high viscosities such as beer and cheese whey.

Lamella pump work technology

With the help of lamella pump work technology of how does the lamella pump work, its homogeneous products work on the principle of centrifugal force. The material to be pumped is placed in a hopper at one end of the pump and is then fed into the barrel through an auger or screw conveyor. The barrel is mounted on a rotating shaft which is powered by an electric motor.

As the barrel rotates, centrifugal force pushes the material out of gaps in the barrel wall where it can be collected in a discharge pipe or other container. The material leaves the barrel through perforations that are cut into its side walls at regular intervals called lamellae.

As more material enters the barrel, it begins to build up between these perforations until there is enough pressure within that part of the pump to push some out through another set of perforations further down on its side wall. This process continues until all of the material has left the hopper and been discharged from one end of the pump.

What is the main difference between a lamella pump and another pump?

Lamella Pump is a pumping device that can transport fluids with big particles and viscous liquid. The lamella pump is used for bone and offal transfer with big particles, and liquid with higher viscosity. What Is The Main Difference Between A Lamella Pump And Another Pump?

The high viscosity of the material and the large size of particles make conventional pumps unable to transport them. Therefore, the lamella pump has been invented as an alternative to these pumps.

- The main difference between a lamella pump and another pump is that the lamella pump can work under high pressure, while other pumps cannot work under high-pressure conditions due to their weak structure.

- The lamella pump has an advantage over many other types of pumps because it can handle high-viscosity liquids without causing cavitation or sludging problems. The stainless steel lamella plate is flexible enough to allow for changes in viscosity without damaging the plate itself or causing cavitation within the system.

- The lamella pump can be used as a substitute for other pumps such as rotary vane pumps, centrifugal pumps, and diaphragm pumps. It can also be used in combination with these other types of pumps to increase efficiency, reduce power consumption and reduce pressure loss.

What are the benefits of a lamella pump?

If you want to better understand how does the lamella pump work? Then you can learn about its strengths. The main advantage of this type of pump is that it can deliver high pressure even at low flow rates. It also provides excellent energy efficiency compared to other types of pumps.

Longer Service Life

Lamella pump has a long service life because of their high quality and good performance. You can use it continuously for many years without maintenance. If you are using Sunrise Lamella Pump which is two years with lifelong free service, then its maintenance cost is low-cost and it has spare parts.

High Shear Force

The lamella pump can generate high shear force due to its large number of small plates. This means it can handle high-viscosity materials with ease. Also, its large surface area ensures that there will be no heat generated during the process which makes it ideal for handling corrosive fluids.

Low Operation Cost

Lamella pump has low operation cost because it has a simple structure, easy installation, and convenient operation. The speed of the pump can be adjusted according to your needs, so you don’t need to buy another one when you need more power or a different speed.

High Efficiency

Since these pumps have small diameter plates and a large number of these plates are arranged in parallel configurations. They can withstand high pressures without breaking down or wearing out quickly like other pumps do when they are exposed to high pressures over a long period of time.

As said above, lamella pumps have high efficiency because of their unique structure which makes them work more efficiently than other pumps in the same category.

Conclusion

Now do you understand how does the lamella pump work? The lamella pump is a new type of pump for pumping solid, powdery, and slurry materials. The material to be pumped gets transferred to a storage tank, from which it falls at the lamellas onto the rotor blades.

When falling the material mixes with the impellor spinning at high speed and creating turbulent flow, causing centrifugal pressure on the rotor blades. And by this centrifugal pressure, the material is pushed up through the lateral points of the blades.