How To Do A Poultry Slaughter Waste Rendering Plant?

How To Do A Poultry Slaughter Waste Rendering Plant?

What Are the Benefits of A Poultry Slaughter Waste Rendering Plant?

If you’re dying to know how to do a poultry slaughter waste rendering plant, you can find the answer in this blog post. The poultry slaughter waste rendering plant is a great way to dispose of your poultry by-products. Not only will you be able to reduce the amount of waste that goes into the landfill, but you’ll also be able to make money off of any fat and protein left over from the process.

These poultry renderings can be used in conjunction with any existing slaughterhouse or meat processing plant, or they can be built as standalone facilities. The following are some of the benefits of building a poultry slaughter waste rendering plant:

1. Low Investment

Poultry independent slaughter waste rendering plant’s investment is relatively low compared with other similar equipment.

By processing your poultry by-products into feedstock, you can sell it back to farmers or use it on your farm for fertilizer or animal feed. This helps save money for both farmers and consumers alike.

2. High Efficiency

Poultry slaughter waste rendering plant has high efficiency, which can save much more energy than other similar equipment. The poultry slaughter waste rendering plant’s operation is simple and convenient.

3. Reduce Landfill Waste

Poultry by-products generated during slaughter can be used for other purposes such as animal feed or fertilizer. This reduces the number of food scraps that end up in landfills each year.

By reducing landfill waste, you’re helping keep chemicals out of the water supply and making the planet healthier overall.

To reduce environmental impact, many companies have started adopting new technologies such as Rendering Poultry Waste Plant and this has been very effective in reducing environmental pollution from this industry.

The main objective behind setting up a rendering plant is to reduce the amount of waste produced by slaughterhouses, which can cause serious health problems if not properly managed.

There are many types of rendering plants available on the market today. But Sunrise equipment such as Exhaust Abatement, Chemical Scrubber, or other products is better than others when it comes to efficiency and performance.

Step 1: Find Customer for End Product

The first step in the business of how to do a poultry slaughter waste rendering plant is to find a customer for your end product. If you are planning to sell it as fertilizer, then you should contact some farmers who are interested in purchasing it.

On the other hand, if you want to sell it as animal feed then you will have to contact companies that produce animal feed and get their feedback about the product.

The customer may be in the form of a slaughterhouse or farm, or it could be a pet food producer. Once you have located the end user, the next step would be to figure out how much material is needed and how much money can be made from selling it.

Step 2: Design the Poultry Slaughter Waste Rendering Plant

The next step is to design the poultry slaughter waste rendering plant. The design should be done in a way that can produce high-quality products that can be sold at a high price. Here are some of the things to consider when designing your poultry slaughter waste rendering plant:

Location

It is important to choose a location that is far from residential areas. You will also need ample space for trucks to drop off waste and pick up animal fat, bone meal, and fertilizer.

Labor Requirements

You will need labor for unloading trucks, weighing waste, mixing ingredients, operating machinery, cleaning equipment, and maintaining an orderly environment at all times.

Equipment Needs

Equipment needed includes scales, mixers, grinders, and blenders as well as other machines required for the rendering processes like centrifuges or separators used for separating fats from bone or meat scraps.

Step 3: Furnish the Plant With Equipment and Supplies

A poultry slaughter waste rendering plant is a meat-processing facility that specializes in turning animal byproducts into useful products such as tallow and lard.

The process of how to do a poultry slaughter waste rendering plant involves several steps, including a collection of the waste, grinding of the material, and separation of various components. The remaining material is then further processed to remove fat and bone fragments before being dried and granulated into feed pellets.

The important step in setting up a poultry slaughter waste rendering plant is to gather all the equipment like a batch cooker needed to complete the process. These include:

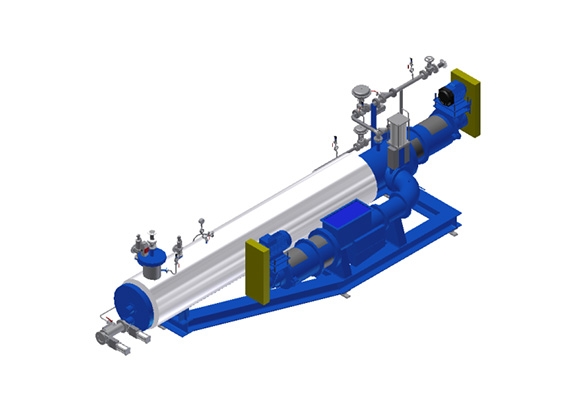

1. Continuous Hydrolyser

The process of Sunrise Continuous Hydrolyser is the most efficient way to get rid of poultry slaughter waste. The process involves mixing the carcasses, feathers, and blood with water and chemicals to produce a high-protein liquid that can be used as animal feed. This method requires a lot of space and equipment, but it also yields a higher profit than grinding or fermenting.

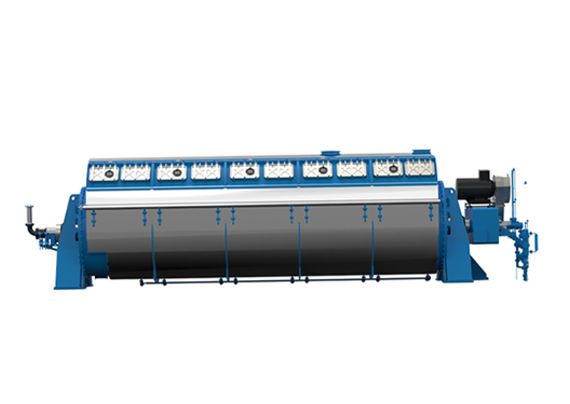

2. Feather Press

Sunrise Feather Press is a machine that presses the feathers out of poultry. It is an essential part of the poultry slaughter waste rendering plant. Feather Press is mainly used in the production of animal feed, feather meal, and feed additives.

The machine consists of a cylindrical drum with a hole in each end, which has a piston plate on one side and a piston rod on the other side. In the middle of this cylinder, there should be two bearings with high strength and low friction coefficient. There are two bearings in one direction so that can withstand pressure from both sides.

3. Disc Dryer

Sunrise Disc Dryers are the most common type of dryer used in poultry slaughter waste rendering plant operations. Disc dryers are machines that dry raw materials by passing them through a rotating drum. They are designed to fit any size operation and allow you to customize your system by choosing from a variety of options and accessories.

Step 4: Hire Staff and Train Them

The tip for running a poultry slaughter waste rendering plant is that you need to hire staff and train them. The first thing you have to do is to hire staff who have experience in this field. They must have good knowledge about how to slaughter and clean up the birds, as well as how to cut them up into parts.

When hiring these people, make sure that they are trained well enough so that they can do their jobs properly. This will help your business run smoothly because nobody wants their employees not doing their jobs right.

You will also need help from other people who know how to operate a rendering plant because they will be able to teach your staff how they can handle these wastes properly. If you do not know how to do a poultry slaughter waste rendering plant, then it is best if you hire someone who does know how to operate one so that they can teach your staff how to do it.

Step 5: Set Up the Plant Operations

The most important thing of how to do a poultry slaughter waste rendering plant you need to do is set up the plant operations. This includes setting up a structure that can support your business and also provide electricity and water supply. You also need to hire people who will work in your slaughterhouse. Make sure they know how to handle chickens and other farm animals properly so that they can maintain good hygiene standards in the slaughterhouse.

What’s more, you must get all the necessary permits and licenses for your business before starting operations. These include getting a business license from your local town hall and also obtaining an environmental permit from local environmental agencies such as the Environmental Protection Agency or Department of Environmental Protection.

Step 6: Obtain Financing for the Plant

You will need money for equipment such as grinders or conveyor belts and also for building expenses such as construction costs and wages for workers who will be hired once the plant begins operating.

Obtaining financing for a major poultry meat processing plant can be a challenge. It takes time, persistence, and effort to find lenders that are willing to finance your project. Many lenders are reluctant to lend money to poultry processing plants because they do not like the risks associated with this type of business.

The best way to convince lenders that your project is viable is through a thorough business plan. Your business plan about how to do a poultry slaughter waste rendering plant should include information about the market conditions in your area and how they affect your company’s ability to compete. It should also include detailed information about how you will operate the plant, what equipment you will use, where it will be located, how many people you intend to hire, etc.

Once you have developed a good business plan, seek out banks or other financial institutions that may be willing to lend money on poultry slaughter waste rendering plants like yours.

Conclusion

By following these steps of how to do a poultry slaughter waste rendering plant you’ll be able to create a rendering plant that can add value to your poultry slaughter waste products. The processing of poultry waste and by-products has many uses, including recycling, energy recovery, creating livestock feed supplements, or reprocessing into paper, rubber, and plastics.

Additionally, the rendering process converts all these materials into valuable, marketable commodities that can be used by the leather, blood meal for pet food, and pharmaceutical industries.