Inside the Beef Rendering Plant: A Closer Look at the Process

Inside the Beef Rendering Plant: A Closer Look at the Process

Beef rendering plant: The Method of beef rendering plant

- Animal byproducts unsuitable for human consumption are processed in meat processing facilities. These by-products originate from slaughterhouses, butcher shops, and meat processing plants, including bones, organs, blood, and fat trimmings. Rendering primarily separates vital components like proteins and lipids from these by-products.

- Wet and dry rendering are the two categories into which the rendering process may be divided. Wet rendering includes cooking the raw materials in steam or boiling water and separating the fat from the particles. On the other hand, the process of dry rendering entails heating the raw materials at high temperatures until the moisture evaporates and the required ingredients are left behind.

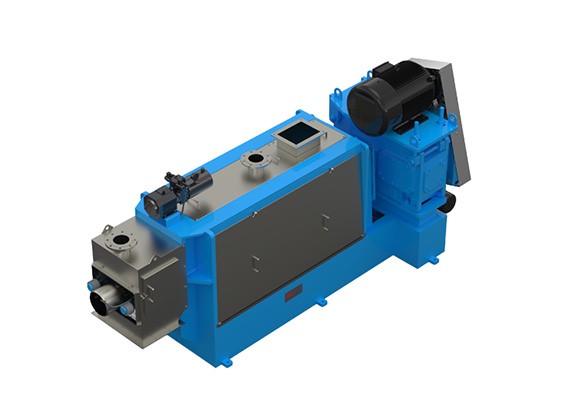

Machine: Fat Screw Press at Sunrise Beef Rendering Plant

The Fat Screw Press from Sunrise beef rendering plant Machine is useful for the meat rendering sector. It is a crucial piece of equipment for creating premium tallow and pressed cake due to its high yield, effective processing capabilities, and simplicity of maintenance. The Fat Screw Press is a continuous mechanical extraction device that may produce significant quantities of fat. It was created with simplicity and efficiency in mind. Its construction includes an industrial gearbox that is often used and a T-type screw press with a hydraulic choke tube on the output end. During the processing step, this choke tube assists in maintaining a specific pressure and regulates it manually or automatically.

The machine at Sunrise Beef Rendering Plant: Fat Filtration

The Sunrise Fat Filtrator is made to remove sludge and fat from expeller presses. The separation of fat from solids is efficient and effective thanks to its novel design. A vibrating screen set up in an inclined position serves as the separator. When the fat and particles contact the screen, the fat pierces it while the solids cling to its surface. The solids are moved to the exit because of the screen’s tilt and vibration. The machine employs a choke tube to manually or automatically modulate pressure throughout processing to maintain a specific pressure. This makes it easier to ensure the machine is operating at the right pressure, making it possible to separate fat from solids effectively and efficiently.

The Beef Meal Machine Factory: An Important Center for Resource Use

A unique facility called the meat meal machine factory turns animal byproducts into premium beef Meals.

Some of these byproducts are offal, bones, and trimmings from the flesh. The raw ingredients are put through several operations at the facility, including grinding, cooking, drying, and pulverizing, to produce a protein-rich meal appropriate for making animal feed. The factory ensures that resources are used as effectively as possible, which helps handle animal waste sustainably.

Utilization of Processing and Resources:

The raw ingredients undergo a series of meticulously planned operations in a beef meal machine plant to achieve optimal resource usage. The raw materials are generally ground in the first phase to ease processing. The pulverized materials are then boiled to remove potentially hazardous microorganisms and improve the finished product’s nutritional value. The material is dried after heating to remove excess moisture, enabling long-term storage. The dried material is ground into a fine meal packed with protein and other necessary elements. Animal feed manufacturing uses this protein-rich meal as a key component, which raises the feed’s total nutritional value.

Innovative Environmental Protection Technology from Jiangsu Sunrise Transforming the Beef Meal Industry:

Jiangsu Sunrise Environmental Protection Technology, a prominent beef meal machine factory supplier, offers modern machinery and solutions. The company aims to provide cutting-edge technology that tackles environmental issues, boosts productivity, and assures sustainable manufacturing. Jiangsu Sunrise provides cutting-edge solutions specifically designed to satisfy the demands of the meat meal sector thanks to a team of professionals and a dedication to research and development.

Jiangsu Sunrise Environmental Protection Technology’s dedication to sustainability, effectiveness, and innovation redefines the beef meal sector. The firm equips meat meal manufacturing facilities with cutting-edge machinery and specialized solutions to improve production, address environmental issues, and fulfil the rising demand for animal meals. Jiangsu Sunrise’s commitment to technology breakthroughs will continue to help the beef meal industry form a more sustainable and successful future as the sector develops.

The Advantages of Beef Meal Equipment:

The usage of bone meal machines benefits farmers, gardeners, and the environment in several ways:

Waste reduction: Bone meal processing equipment turns waste from the meat industry into a useful resource, decreasing landfill trash and the agriculture sector’s carbon footprint.

- Nutrient-Rich Fertilizer:

Bone meal is a fantastic source of nutrients that plants need to grow, enhancing soil fertility and plant health.

- Sustainable Agriculture:

By supporting more environmentally friendly and sustainable farming methods, farmers may lessen their dependency on synthetic fertilizers by employing bone meal.

- Economical Solution:

Making bone meals on-site with a bone meal machine may be more economical for small-scale farms and gardeners than buying commercial fertilizers.

- Animal Feed Supplement:

Bone meal may also be used as an animal feed supplement, supplying vital nutrients to cattle in addition to its usage as a fertilizer.

Introducing the Sunrise Meat Rendering Plant Device:

The Sunrise Meat Rendering Machine is a cutting-edge solution created to satisfy the meat rendering industry’s changing demands. This machine has revolutionized rendering plant operations with its cutting-edge features. One of the main issues with traditional rendering techniques is the noxious smell and air pollution they produce. The Sunrise Meat Rendering Machine allays these worries by including cutting-edge odour and emission control technology. The environmental effect of the facility is greatly diminished by this technology, which also processes emissions.

Conclusion: The management of animal byproducts sustainably depends heavily on the meat rendering industry. Innovative technologies like the Sunrise Meat Rendering Machine are essential to tackling the issues rendering plants encounters as the demand for rendered goods keeps rising. The SunRisebeef rendering plant is transforming the meat rendering business and establishing new benchmarks for years to come thanks to its exceptional efficiency, environmental friendliness, automation, adaptability, and safety features. Our team is a young people with ideals, ambitions and innovations.