Custom Meal Cooler: Cooling Solutions for Industrial Needs

Custom Meal Cooler: Cooling Solutions for Industrial Needs

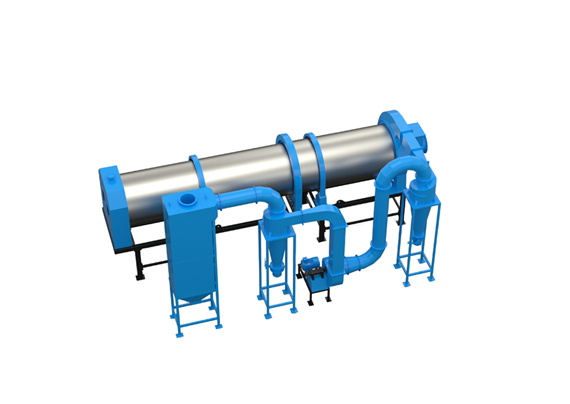

As part of a food-processing operation, preserving the quality and safety of your products is a top priority. Sunrise’s Meal Cooler has been an industry standard for many years, thanks to its innovative design and superior performance.

Understanding the Meal Cooler: What is Meal Cooler?

The Sunrise Meal Cooler, engineered by Sunrise, stands as a vital link in the chain of industrial processes that follow drying. This innovative cooling solution plays a pivotal role in stabilizing the temperature of processed materials, preventing the development of harmful bacteria, and preserving product integrity. By utilizing advanced cooling mechanisms, the meal cooler facilitates the gradual reduction of temperature, a process that is essential to prevent the onset of spoilage and maintain product freshness.

Features that Set Sunrise Meal Cooler Apart

1. Precision Cooling: The Sunrise Meal Cooler boasts precision cooling capabilities, ensuring that products are cooled to the desired temperature range without compromising their structural integrity. This is of paramount importance in industries such as fish meal and poultry, where rapid temperature changes can lead to quality degradation.

2. Energy Efficiency: In an era where sustainability is a global concern, the Sunrise Meal Cooler stands out for its energy-efficient design. By incorporating innovative cooling technologies, it minimizes energy consumption while maximizing cooling efficiency, resulting in substantial cost savings for businesses.

3. Customizable Configurations: Recognizing the diverse requirements of different industries, the Sunrise Meal Cooler offers customizable configurations. This adaptability ensures that the cooling process is tailored to suit the specific characteristics of the processed materials and the production environment.

4. Robust Build: Industrial settings demand equipment that can withstand the rigors of continuous operation. The Sunrise Meal Cooler’s robust construction and high-quality materials guarantee longevity and reliability, even in demanding conditions.

User-Friendly Interface: Navigating complex industrial equipment can be a challenge. However, the meal cooler features a user-friendly interface that simplifies operation and allows for easy monitoring of the cooling process, making it accessible for operators of varying expertise levels.

Applications Across Industries

1. Rendering Plants: In rendering plants, the meal cooler plays a crucial role in cooling down rendered materials before they are further processed or stored. Efficient cooling prevents the growth of harmful microorganisms and preserves the quality of the rendered products.

2. Fish Meal Industry: For the fish meal industry, maintaining the freshness of fish-based products is paramount. The Sunrise Meal Cooler ensures that fish meal is cooled to the appropriate temperature quickly, preventing spoilage and maintaining the nutritional value of the final product.

3. Poultry Industry: Poultry products require rapid cooling to prevent bacterial growth. The Sunrise Meal Cooler’s precision cooling capabilities make it an ideal solution for poultry processing, ensuring that chicken meals and other poultry products remain safe for consumption.

4. Meat Bone Industry: Cooling is crucial in the meat bone industry to preserve the quality of bone meal and other byproducts. The Sunrise Meal Cooler’s ability to efficiently reduce temperatures while maintaining product integrity is essential in this context.

Design Excellence of Sunrise Meal Cooler

1. Simple yet Robust Construction

The Sunrise Meal Cooler boasts a simple and sturdy construction that minimizes the number of components and wearing parts. This design approach not only enhances its overall efficiency but also ensures its reliability over extended operational periods. Manufacturers understand the need for a cooling solution that can withstand the demands of continuous production, making the Sunrise Meal Cooler an ideal choice.

2. Innovative Cooling Principle

At the heart of the Sunrise Meal Cooler lies a cooling principle based on the counter flow of cooling air and hot product. This ingenious concept facilitates optimal heat exchange, enabling rapid and effective cooling of processed products. By ensuring that the cooling air and the hot product move in opposite directions, this cooling principle maximizes the cooling efficiency, resulting in products with extended shelf life and maintained quality.

3. Stator and Rotor Composition

The essential components of the Sunrise Meal Cooler are the stator and rotor, both crafted from mild steel. The stator, designed as a cylindrical pipe with end plates and supports, creates a controlled environment for the cooling process. Equipped with sight glasses featuring cleaning brushes, it ensures easy monitoring and maintenance. The stator’s air intake and outlet openings are strategically designed with counter flanges, optimizing airflow management.

4. Agitating Arms and Paddles for Optimal Cooling

The rotor, another critical component, comprises a rotor pipe equipped with agitating arms and paddles. These components play a crucial role in lifting the product into the cold air stream, facilitating efficient cooling. Adjustable paddles give operators the ability to control the retention time in the cooler, allowing for customization based on specific product requirements.

Technical Brilliance of Sunrise Meal Cooler

1. Efficient Cooling Models

Sunrise offers a range of Meal Cooler models, each designed to cater to specific production volumes. The LF-1600-6000 model, with a volume of 10 cubic meters, can handle 2300 kg/h, making it a suitable choice for moderate processing needs. On the other hand, the LF-1600-9000 model has a volume of 18 cubic meters and can process 3350 kg/h, catering to higher production demands.

2. Precision and Flexibility

These models showcase exceptional engineering prowess. With dimensions of 7800mm in length, 4900mm in width, and 2400mm in height, the LF-1600-6000 model provides ample space for efficient cooling. Similarly, the LF-1600-9000 model, with dimensions of 11000mm x 4900mm x 1800mm, is designed to accommodate larger quantities. Both models have a rotating speed of 24 revolutions per minute, ensuring a consistent cooling process.

3. Customizable Solutions

Recognizing that different customers have varying requirements, Sunrise offers customization options. These options allow manufacturers to tailor the meal cooler to their specific needs, ensuring optimal performance and compatibility with their production processes.

4. The Manufacturer Behind the Innovation: Sunrise

Sunrise, the visionary manufacturer behind the Meal Cooler, has demonstrated a commitment to revolutionizing food processing technologies. With a focus on simplicity, efficiency, and reliability, Sunrise has redefined the cooling process, ensuring that food products maintain their quality, freshness, and safety.

Conclusion

In a world where food preservation is of paramount importance, the Sunrise Meal Cooler emerges as a crucial player, providing cutting-edge solutions that redefine cooling processes across the food industry. Its innovative design, technical prowess, and commitment to customer satisfaction make it a symbol of excellence in the realm of food processing and preservation.

Categories

Recent Posts

-

What is harmless treatment of sick and dead animals and poultry(rendering plant) A Key Initiative to Protect the Ecological Environment and Food Safety.

March 6, 2025 -

How does Sunrise rendering plant equipment destroy avian influenza viruses in livestock poultry carcasses

March 5, 2025 -

Sunrise Rendering Thailand Exhibition

March 5, 2025