Enhancing Sustainability & Nutrition with a Meat Meal Rendering Plant

Enhancing Sustainability & Nutrition with a Meat Meal Rendering Plant

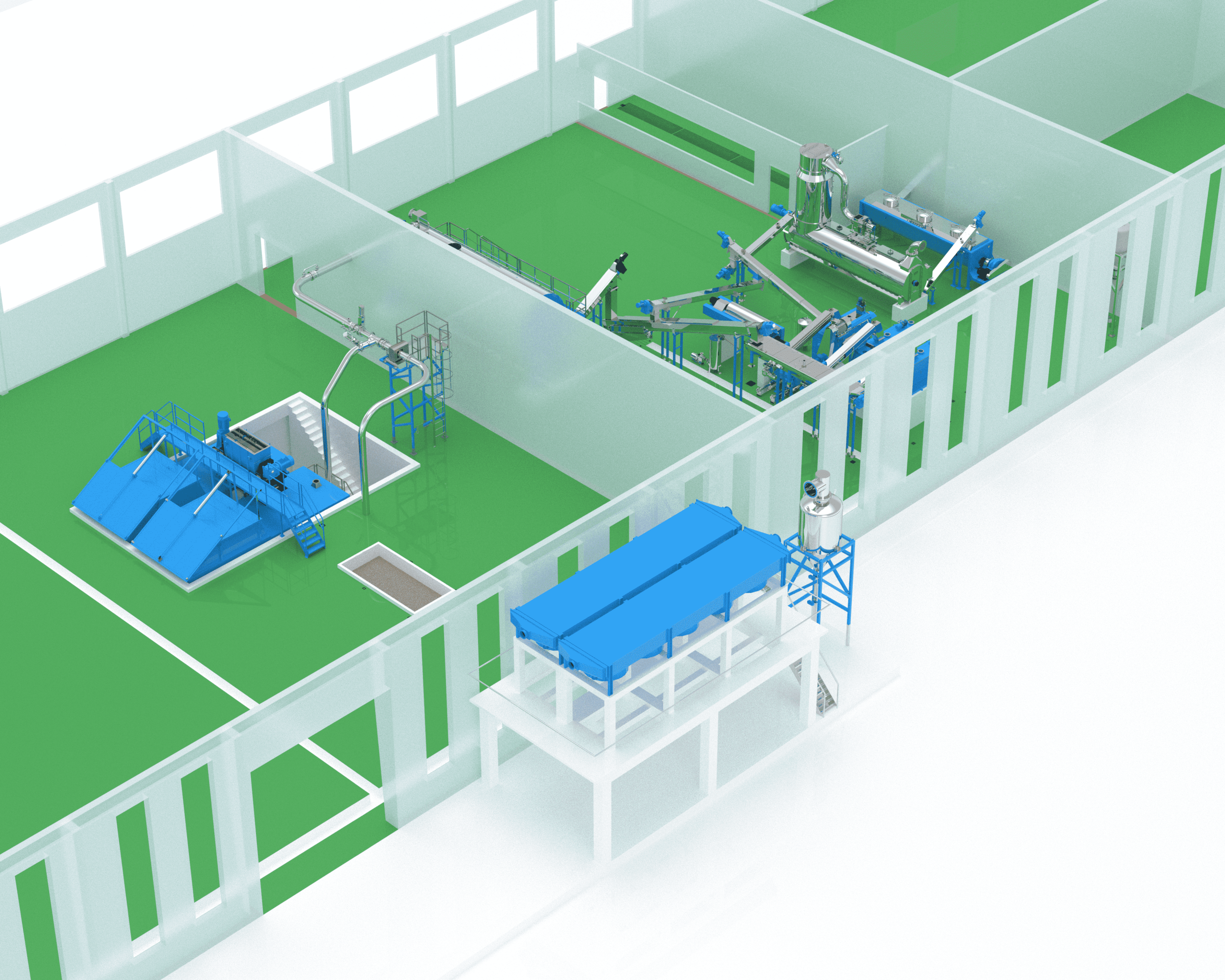

In the pursuit of sustainability and maximizing the potential of animal resources, the Meat Meal Rendering Plant has emerged as a revolutionary solution. This advanced machine, designed by SunRise, is capable of transforming whole animal carcasses into a fine powder known as a meat bone meal. This versatile product serves as a protein-rich additive in animal feed and a valuable organic fertilizer.

How Does the Meat Bone Meal Machine Work?

The Meat Bone Meal Machine plays a crucial role in converting animal by-products into usable and valuable resources. By employing a series of advanced processes, it extracts the bone marrow from raw animal bones and transforms it into a nutrient-dense powder. Here’s a simplified breakdown of the machine’s operation:

1. Batch Cooker: The animal carcasses are introduced into the batch cooker, where they are subjected to high temperatures and pressure. This initial cooking process helps break down the tissues and separate the bone marrow from the bones.

2. Disc Dryer: The extracted mixture is then transferred to the disc dryer, where heat and airflow facilitate the drying process. This step reduces the moisture content of the mixture and prepares it for further processing.

3. Fat Screw Press: The dried mixture is directed to the fat screw press, which efficiently separates the fat from the solid components. This separation allows for the extraction of valuable fats that can be used in various applications.

4. Lamella Pump: The processed material is then pumped into the lamella pump, which aids in further separation and removal of any remaining impurities.

5. Pre-Crusher: The refined material is passed through a pre-crusher, which reduces the particle size and ensures a consistent texture in the final product.

6. Continuous Cooker: The pre-crushed material is then transferred to the continuous cooker, where it undergoes a continuous heating process. This ensures the complete breakdown of proteins and sterilizes the material.

7. Material Bin: After continuous cooking, the resulting meat bone meal is collected in a material bin, ready for packaging or further processing.

8. Fat Filtrator and Tallow Pump: The fat separated in the fat screw press is filtered using a fat filtrator, removing any impurities, and then transferred using a tallow pump for storage or utilization.

Types of Animal Bones Used for Making Meat Bone Meal

The Meat Bone Meal Machine is capable of processing various types of animal bones to produce high-quality meat bone meals. These include:

1. Bone Meal: Raw bones are ground into a fine powder, which serves as the primary ingredient for most meat bone meal machines.

2. Whole Animal Bones: Typically broken down into smaller pieces, these bones are used in cases where a coarser texture is desired, allowing for easier handling and usage.

3. Fish Bones: Easily broken down into smaller bones similar to animal bones, fish bones are a valuable resource for creating meat bone meals.

Benefits of Using the Meat Meal Rendering Plant

The Meat Bone Meal Machine offers numerous benefits for its users, benefiting a wide range of individuals and industries. Let’s explore some of these advantages:

1. Animal Feed Industry: Livestock, poultry, and aquaculture industries benefit from the high-quality protein content provided by meat bone meal. This sustainable protein source enhances animal nutrition, promoting healthier growth and reducing the reliance on conventional feed additives.

2. Fertilizer Production: The nutrient-rich composition of meat bone meal makes it an excellent organic fertilizer. By incorporating meat bone meal into soil amendments, agricultural practices become more sustainable and environmentally friendly.

3. Waste Reduction and Sustainability: The Meat Bone Meal Machine enables the utilization of animal by-products that would otherwise go to waste. It supports sustainable practices by repurposing resources that might have otherwise ended up in landfills or posed environmental challenges.

4. Cost-Effective Solution: For industries that rely on animal-based products, the Meat Bone Meal Machine offers a cost-effective solution. It allows for the utilization of the entire animal carcass, maximizing the value derived from each animal and reducing the need for additional raw materials. This can result in significant cost savings and improved profitability.

5. Enhanced Food Safety: The continuous cooking and sterilization processes employed by the machine ensure the elimination of pathogens and harmful bacteria, making the meat bone meal safe for consumption by animals. This promotes animal health and reduces the risk of disease transmission within livestock populations.

Conclusion

The Meat Bone Meal Machine, developed by SunRise, represents a significant advancement in the utilization of animal by-products. It’s efficient processes and versatile output offer a range of benefits to the animal feed and agricultural industries. By extracting valuable components from animal carcasses and converting them into meat bone meals, the machine promotes sustainability.

Categories

Recent Posts

-

A guide to Scientists poultry farming on farms: reducing costs, increasing efficiency, and protecting the ecosystem

August 27, 2025 -

Global treatment and sustainable utilization of slaughterhouse waste

August 13, 2025 -

Choosing the right equipment can solve all the problems in animal fat processing

August 1, 2025