Oil Screw Press Machine: Efficient Extraction of Oil from Seeds

Oil Screw Press Machine: Efficient Extraction of Oil from Seeds

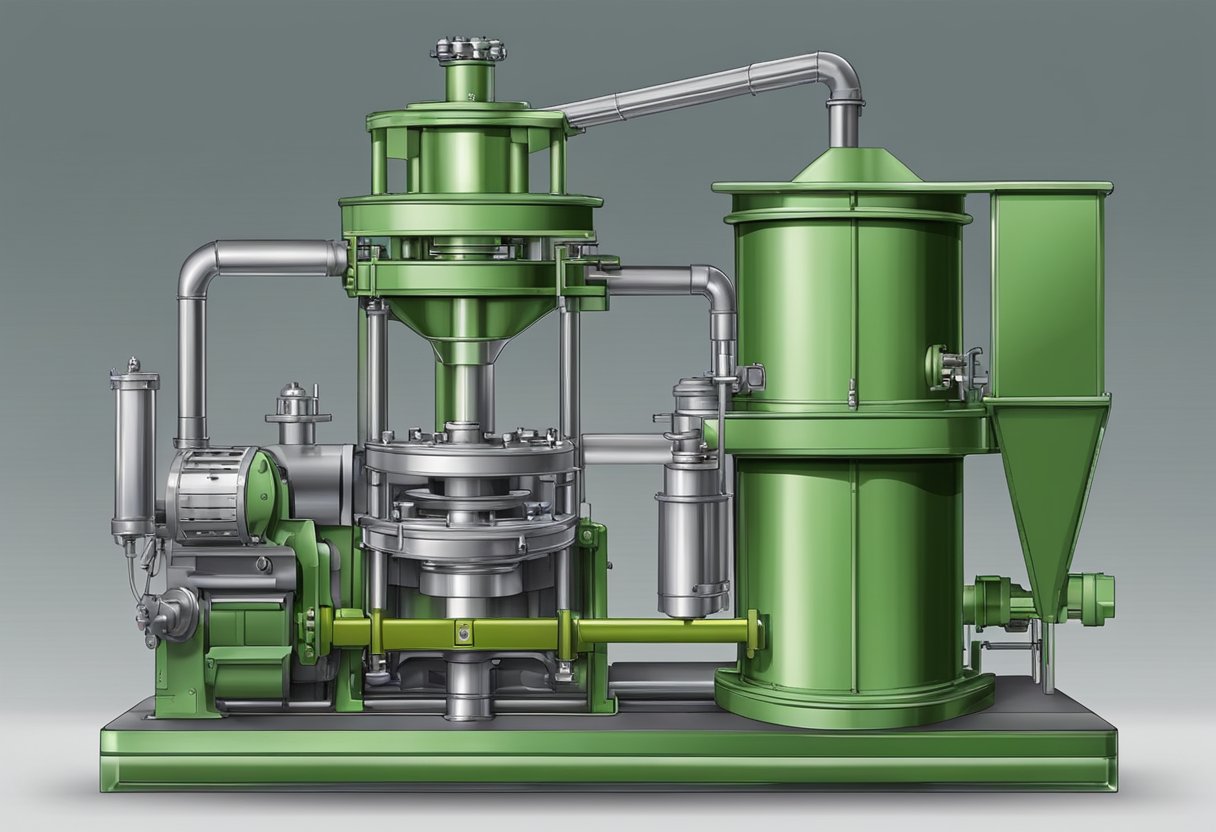

An oil screw press machine is a mechanical device used to extract oil from seeds and nuts. It is a vital tool in the oil extraction industry, as it enables the production of high-quality oil in large quantities. The machine works by pressing the seeds or nuts to extract the oil, which is then collected and processed further.

The oil screw press machine has been in use for many years and has undergone significant improvements to enhance its efficiency and productivity. The machine’s design is simple, making it easy to operate and maintain, even for those with little technical knowledge. Furthermore, the machine’s ability to produce high-quality oil makes it a popular choice for many oil extraction companies worldwide.

Overall, the oil screw press machine is an essential tool in the oil extraction industry. Its simplicity, efficiency, and ability to produce high-quality oil make it a valuable asset to any oil extraction company. As such, it is crucial to understand how the machine works and its benefits to ensure optimal productivity and profitability in the oil extraction industry.

Overview of Oil Screw Press Machines

Oil screw press machines are used in the extraction of oil from various seeds and nuts. They are designed to extract oil from materials such as soybean, peanut, cottonseed, rapeseed, sunflower seed, sesame, and palm kernel, among others. The machines work by pressing the seeds or nuts with a screw, which extracts the oil from them.

The oil screw press machine is a compact and efficient machine that can be used in small and large-scale oil extraction operations. It is easy to operate and requires minimal maintenance, making it a popular choice among oil producers.

One of the advantages of using oil screw press machines is that they produce high-quality oil that is free from impurities. The machines are designed to extract oil at low temperatures, which helps to preserve the natural flavor and aroma of the oil.

Oil screw press machines come in different sizes and capacities, depending on the needs of the user. Some machines are designed for small-scale operations, while others are suitable for large-scale commercial production. The machines are also available in manual and automatic models, with the latter being more efficient and easier to operate.

In conclusion, oil screw press machines are an essential tool in the oil extraction industry. They are efficient, easy to operate, and produce high-quality oil that is free from impurities. With the different sizes and capacities available, oil producers can find a machine that suits their specific needs.

Types of Oil Screw Press Machines

Hydraulic Oil Press

Hydraulic oil press machines are designed to extract oil from different types of seeds and nuts. They are equipped with a hydraulic pump that generates high pressure to squeeze the oil out of the seeds. These machines are widely used for processing sesame, peanuts, walnuts, almonds, and other oilseeds. The hydraulic oil press is preferred by many users due to its high oil yield and low energy consumption.

Mechanical Screw Press

Mechanical screw press machines are also used for extracting oil from seeds and nuts. They work by pressing the seeds against a metal cage with a screw. As the screw turns, the pressure increases, and the oil is squeezed out of the seeds. These machines are suitable for processing a wide range of oilseeds, including soybeans, sunflower seeds, rapeseeds, and more. The mechanical screw press is known for its high efficiency and low maintenance requirements.

Overall, both hydraulic and mechanical screw press machines are reliable and efficient tools for extracting oil from various seeds and nuts. The choice of machine depends on the type of oilseed being processed and the desired output.

Components and Functionality

Pressing Screw

The pressing screw is the primary component of the oil screw press machine. It is responsible for compressing and squeezing the oilseed to extract oil. The screw is made of high-quality steel and is designed to withstand high pressure and temperature. The shape and size of the screw determine the type of oilseed that can be processed.

Barrel

The barrel is the housing unit for the pressing screw. It is made of high-quality steel and is designed to withstand high pressure and temperature. The barrel is also equipped with a heating system that ensures the oilseed is heated to the optimal temperature for oil extraction.

Drive Mechanism

The drive mechanism is responsible for powering the pressing screw. It is made up of a motor, gearbox, and other components that work together to drive the screw. The motor provides the power, while the gearbox ensures that the screw rotates at the optimal speed.

Heating System

The heating system is an essential component of the oil screw press machine. It is responsible for heating the oilseed to the optimal temperature for oil extraction. The heating system is usually made up of a heating coil that is wrapped around the barrel. The temperature of the heating coil is controlled by a thermostat, which ensures that the oilseed is heated to the optimal temperature for oil extraction.

In summary, the oil screw press machine is a sophisticated piece of equipment that is designed to extract oil from various oilseeds. The pressing screw, barrel, drive mechanism, and heating system are the primary components of the machine. Each component plays a vital role in the oil extraction process, and their functionality is critical to the overall performance of the machine.

Extraction Process

Seed Preparation

Before the pressing operation, the seeds need to be properly prepared. This involves cleaning, drying, and cracking the seeds. Cleaning is done to remove any impurities or foreign materials from the seeds. Drying is done to reduce the moisture content of the seeds, which helps to increase the yield of oil. Cracking the seeds is done to increase the surface area of the seeds, which helps to improve the efficiency of the pressing operation.

Pressing Operation

The pressing operation is the heart of the oil extraction process. The screw press machine applies pressure to the seeds to extract the oil. The seeds are fed into the machine through a hopper and are compressed by the screw. As the seeds are compressed, the oil is forced out through the small openings in the press cage. The oil is then collected in a container below the machine.

Oil Filtration

After the oil has been extracted, it needs to be filtered to remove any impurities or solids. This is done using a filter press or a centrifuge. The filter press uses a series of filter plates to separate the oil from any solids or impurities. The centrifuge uses centrifugal force to separate the oil from any solids or impurities. The filtered oil is then ready for use or further processing.

Overall, the oil screw press machine is a reliable and efficient way to extract oil from seeds. With proper seed preparation, pressing operation, and oil filtration, high-quality oil can be produced.

Performance Metrics

Extraction Efficiency

The efficiency of an oil screw press machine is a critical performance metric. It determines the amount of oil that can be extracted from a given amount of raw material. The extraction efficiency of a machine can be influenced by various factors, such as the type of raw material, the moisture content, and the operating conditions.

A good oil screw press machine should have a high extraction efficiency, which means it can extract a significant amount of oil from the raw material. The extraction efficiency can be improved by optimizing the machine’s design and operating conditions.

Operation Speed

The operation speed of an oil screw press machine is another important performance metric. It determines the amount of oil that can be produced per unit time. The operation speed of a machine can be influenced by various factors, such as the type of raw material, the moisture content, and the operating conditions.

A good oil screw press machine should have a high operation speed, which means it can produce a significant amount of oil per unit time. The operation speed can be improved by optimizing the machine’s design and operating conditions.

Machine Durability

The durability of an oil screw press machine is a critical performance metric. It determines the machine’s lifespan and maintenance requirements. The durability of a machine can be influenced by various factors, such as the quality of materials used, the design, and the operating conditions.

A good oil screw press machine should have a high durability, which means it can last for a long time with minimal maintenance requirements. The durability can be improved by using high-quality materials, optimizing the machine’s design, and following proper maintenance procedures.

In summary, the performance metrics of an oil screw press machine include extraction efficiency, operation speed, and machine durability. These metrics can be improved by optimizing the machine’s design and operating conditions. A good oil screw press machine should have high values for these performance metrics to ensure efficient and reliable oil production.

Applications and Uses

Oil screw press machines are versatile and useful tools that have a wide range of applications across different industries. Here are some of the common uses of oil screw press machines:

Food Industry

One of the primary uses of oil screw press machines is in the food industry. These machines are used to extract oil from various food products such as seeds, nuts, and fruits. The extracted oil is then used for cooking, baking, and other food preparation purposes. Oil screw press machines are also used to produce cooking oil on a large scale for commercial purposes.

Biofuels Production

Oil screw press machines are also used in the biofuels production industry. They are used to extract oil from various crops such as soybeans, rapeseed, and sunflower seeds, which are then converted into biodiesel. Biodiesel is a renewable and environmentally friendly fuel that can be used in diesel engines without any modifications.

Oil screw press machines are also used in the production of other biofuels such as ethanol and biogas. These machines are used to extract oil from crops such as corn and sugarcane, which are then converted into biofuels.

Overall, oil screw press machines are versatile and useful tools that have numerous applications across different industries. They are essential for the production of cooking oil, biodiesel, and other biofuels.

Categories

Recent Posts

-

What is harmless treatment of sick and dead animals and poultry(rendering plant) A Key Initiative to Protect the Ecological Environment and Food Safety.

March 6, 2025 -

How does Sunrise rendering plant equipment destroy avian influenza viruses in livestock poultry carcasses

March 5, 2025 -

Sunrise Rendering Thailand Exhibition

March 5, 2025