Poultry Rendering Plant Manufacturers: Sunrise and Other Key Players

Poultry Rendering Plant Manufacturers: Sunrise and Other Key Players

Poultry rendering plants play a critical role in the sustainability and efficiency of the poultry industry. They help convert waste materials from the poultry processing chain into valuable by-products such as protein meals, fats, and oils. With a growing global demand for sustainable solutions, rendering plant manufacturers have become increasingly important.

Sunrise: A Shining Example of Excellence Poultry Rendering Plant Manufacturer

Sunrise, a prominent rendering plant manufacturer, has been at the forefront of the industry for several years. They specialize in the design, production, and installation of high-quality poultry rendering equipment. The company prides itself on its commitment to sustainability and efficiency, continuously striving to improve its processes and products.

Sunrise offers a wide range of solutions, catering to both small-scale and large-scale poultry processing facilities. Their equipment is designed to maximize resource utilization and minimize environmental impact. This is achieved through various innovative features such as odor control systems, energy recovery systems, and advanced processing techniques.

Innovations and Future Trends in Poultry Rendering

The poultry rendering industry is evolving rapidly, with manufacturers continuously working to develop innovative solutions to improve efficiency and sustainability. Some of the recent trends and innovations in this space include:

Waste-to-energy systems:

These systems convert waste materials from the rendering process into valuable energy sources, such as biogas, electricity, or heat. This reduces the reliance on fossil fuels and contributes to a circular economy.

Advanced odor control technologies:

As communities become more concerned about the environmental impact of rendering plants, manufacturers are developing new and improved odor control systems. These systems help reduce odors and improve air quality around the facility. Automation and Industry 4.0: Many rendering plant manufacturers are adopting advanced automation technologies to improve process efficiency, reduce labor costs, and enhance product quality.

How to Choose the Right Poultry Rendering Plant Manufacturers?

Choosing the right poultry rendering plant manufacturer is crucial in ensuring that your business achieves the desired level of efficiency, productivity, and profitability. Here are some factors to consider when choosing a poultry rendering plant manufacturer:

1. Experience and Reputation:

Look for a manufacturer with extensive experience in the poultry rendering industry and a strong reputation for delivering high-quality products and services. Check for customer reviews, testimonials, and industry awards to gauge their reputation.

2. Product Quality and Customization:

Ensure that the manufacturer offers products that meet your specific needs and standards. Look for manufacturers that offer customized solutions to meet your unique requirements.

3. Technology and Innovation:

Choose a manufacturer that utilizes the latest technology and innovation in their products and services. This ensures that your poultry rendering plant operates at optimal efficiency, reduces downtime, and maximizes productivity.

4. Cost:

Compare prices and value for money offered by different manufacturers. Choose a manufacturer that offers competitive prices without compromising on product quality or service.

5. After-Sales Service and Support:

Choose a manufacturer that offers comprehensive after-sales service and support, including installation, training, maintenance, and repair services. This ensures that your plant operates at peak efficiency and minimizes downtime.

Sunrise Poultry Rendering Plant Machine: Feather Press

The Feather Press is a versatile machine that can be used in a variety of industries, including feather meal, starch, distiller’s grains, pulp, sugar, sludge, and others. Its primary purpose is to remove excess moisture from these materials before they are dried, making them easier to handle and store.

One of the key advantages of the Feather Press is its small power configuration and low dehydration cost. This makes it a cost-effective option for businesses that need to dehydrate large quantities of materials on a regular basis. The machine is also designed for continuous production, which means that it can operate around the clock without the need for frequent stops or maintenance.

Sunrise Poultry Rendering Plant Machine: Shell and Tube Condenser

The Shell and Tube Condenser comes in two types: Vertical condenser (LSLN) and horizontal condenser (WSLN). The machine operates by passing the process vapors through the tubes while cooling water passes over the external surface in a counter-flow arrangement. This process condenses the vapors, which can then be collected and used in other processes, such as cooking or heating.

The Shell and Tube Condenser is designed with captive loose flange connections, making it easy to disassemble and clean. This feature helps to ensure that the condenser operates at peak efficiency at all times.

Sunrise Poultry Rendering Plant Machine: Vacuum Pump Unit

Vacuum Pump Unit works by compressing air and extracting condensed water, which helps to achieve the purpose of material drying and wastewater collection. This feature makes the Vacuum Pump Unit a highly useful addition to the Shell and Tube Condenser, especially for businesses that need to process large quantities of materials quickly and efficiently.

Vacuum Pump Unit has several applications in material drying. When used in conjunction with the Shell and Tube Condenser, the unit can help to remove excess moisture from materials before they are dried. This can be especially beneficial for businesses that need to dry materials quickly and efficiently, such as those in the poultry or food processing industries.

Conclusion

Poultry rendering plant manufacturers, including Sunrise and others, play a crucial role in the poultry industry’s drive toward sustainability and efficiency. By continuously innovating and developing cutting-edge solutions, these companies are helping the industry meet the growing global demand for protein while reducing its environmental impact. As technology continues to advance, we can expect even more exciting developments in the world of poultry rendering.

Categories

Recent Posts

-

What is harmless treatment of sick and dead animals and poultry(rendering plant) A Key Initiative to Protect the Ecological Environment and Food Safety.

March 6, 2025 -

How does Sunrise rendering plant equipment destroy avian influenza viruses in livestock poultry carcasses

March 5, 2025 -

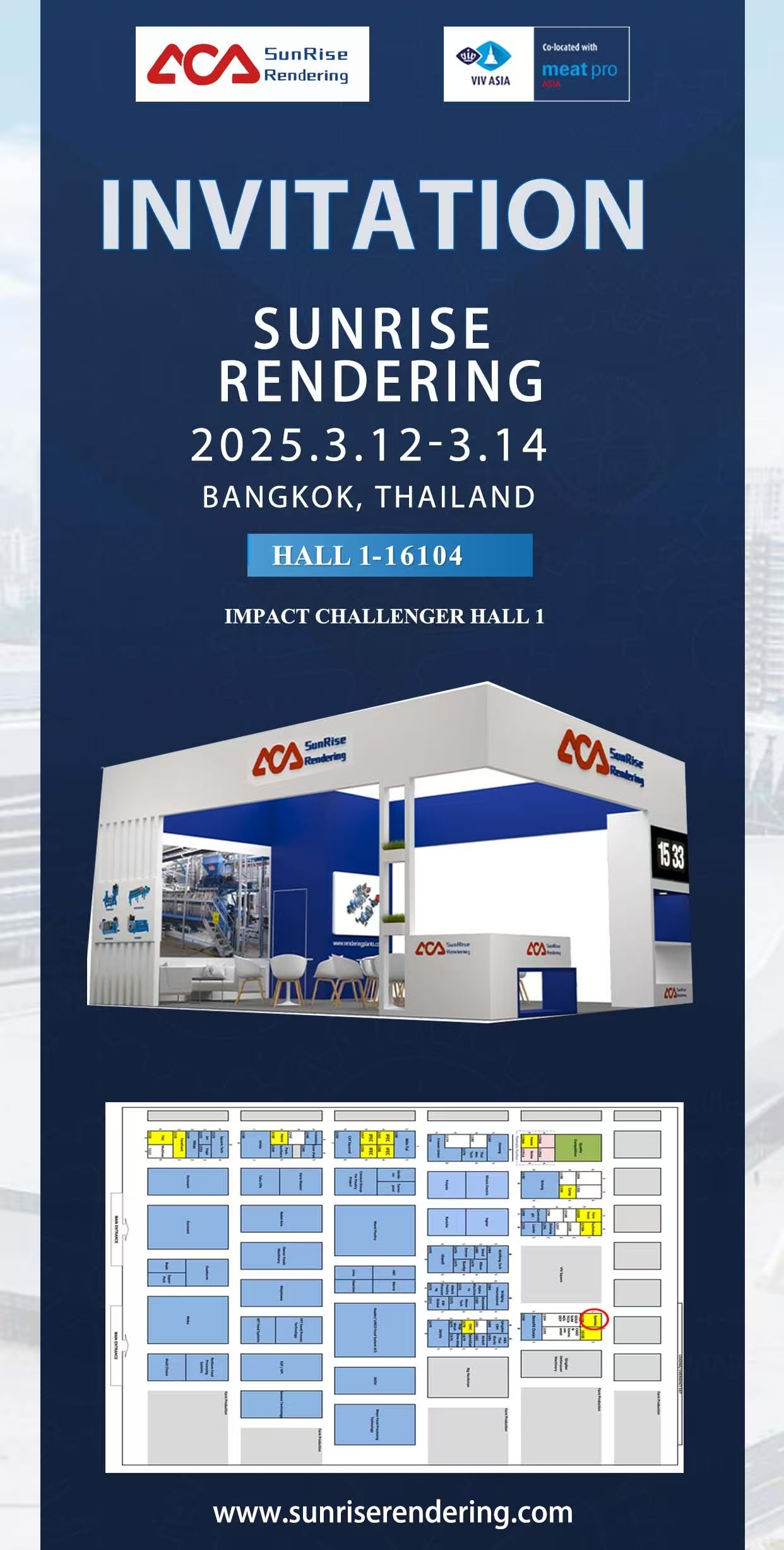

Sunrise Rendering Thailand Exhibition

March 5, 2025