Poultry Rendering Plant: Turning Waste into Valuable Resources

Poultry Rendering Plant: Turning Waste into Valuable Resources

What does poultry rendering plant mean?

The demand for poultry products is consistently rising in today’s society. Because of this, the poultry business produces a lot of waste, including feathers, blood, and offal. But many people need to be aware that this waste may be converted into useful resources through poultry rendering. Finding creative solutions to decrease waste and the environmental effect and sustainable agriculture has received increasing attention in recent years. The function of poultry rendering plant is one frequently ignored part of sustainable agriculture. These facilities are crucial for ensuring that the poultry industry works ecologically responsibly since they treat waste and byproducts from poultry.

Future Guidelines and Improvements in Rendering:

The poultry rendering market is expanding quickly, and producers are always developing new ideas to boost productivity and sustainability. Recent developments and trends in this field include the following:

- Technologies for advanced smell control:

As communities’ concerns over the environmental effects of rendering facilities grow, manufacturers are creating new and enhanced odour control systems. Air quality surrounding the facility is improved, and smells are reduced thanks to these technologies. Automation and Industry 4.0: To increase process efficiency, lower labour costs, and improve product quality, many rendering plant manufacturers are implementing cutting-edge automation technology.

- Waste-to-energy systems:

These systems transform rendered-out waste materials into useful energy sources like biogas, electricity, or heat. As a result, there is less reliance on fossil fuels, and the circular economy is strengthened.

The Rendering Plant Machine: Feather Press:

Feather Press is a flexible machine that may be utilized in several sectors, including feather meal, starch, distiller grains, pulp, sugar, sludge, etc. It is found in the Sunrise Poultry Rendering Plant. Its main goal is to drain the excess moisture from these materials before drying them, making them simpler to handle and store. The Feather Press’s cheap cost of dehydration and minimal power configuration are two of its main features. For companies that frequently need to dehydrate huge amounts of products, this makes it a cost-effective choice. Additionally, the machine can run continuously without regular breaks or maintenance because of its continuous production capabilities.

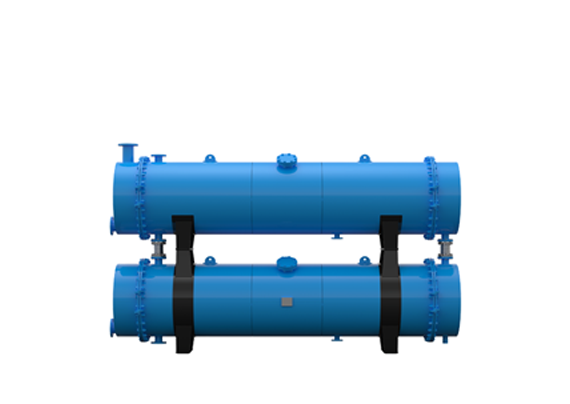

Shell and Tube Condenser at SunRise Poultry Rendering Plant:

Vertical condensers (LSLN) and horizontal condensers (WSLN) are the two varieties of Shell and Tube Condensers available. The machine forces process vapours down the tubes as cooling water flows in a counter-flow pattern over the exterior surface. The vapours are condensed by this process, which allows for their collection and subsequent usage in other procedures like heating or cooking. With captive loose flange connections, the Shell and Tube Condenser is intended to be simple to remove and clean. This function aids in ensuring that the condenser always performs at maximum efficiency.

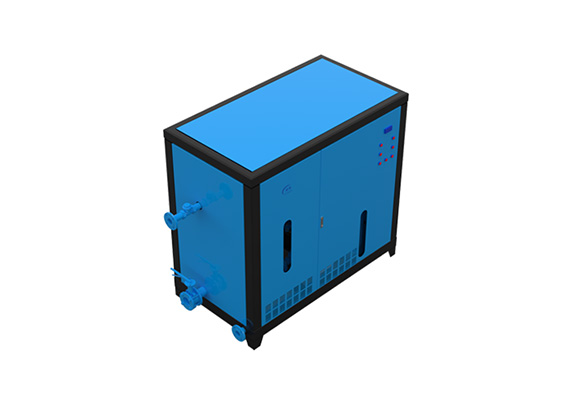

The machine at the Sunrise Poultry Rendering Plant: Vacuum Pump Unit

To meet the goals of material drying and wastewater collection, vacuum pump units operate by compressing air and removing condensed water. The Vacuum Pump Unit is a very helpful addition to the Shell and Tube Condenser because of its functionality, especially for companies that need to handle huge amounts of materials rapidly and effectively. Several uses for vacuum pump units exist in the drying of materials. The device can assist in removing extra moisture from materials before they are dried when used with a Shell and Tube Condenser. Businesses that must swiftly and effectively dry goods, such as those in the poultry or food processing sectors, may find this very helpful.

How Should a Poultry Rendering Plant Operate? How Can You Choose Better Chicken?

The technique of “rendering” removes the fat from cooked chicken. The extracted fat is subsequently utilized in various products, including margarine, soap, and cooking oil. Ensuring that all equipment is functioning correctly is crucial while running a chicken rendering factory. This entails ensuring that none of the controls are broken, that no motors, pipes, or pipelines are obstructed, and that all other parts are in good working condition. It’s time to start converting your raw materials into usable goods once these inspections have been accomplished.

To do this, bones may be reduced to a paste or even made into a liquid. The amount you wish to make daily and the machine you have purchased will determine this. Ensure that all work is done by you alone, and never permit anyone else to use your equipment without your consent. If you permit others to use your equipment, they must do so per all relevant laws and rules. If there is a problem while it is operating, please notify us right away; Please get in touch with us immediately away if you have any issues while operating so that we can start offering technical help.

A Poultry Rendering Plant Could Be the Solution:

A rendering facility for poultry can be your best option if you’re seeking a solution to your waste disposal issues. Using a poultry rendering facility, you may get rid of all the fat and feathers from your butchered chickens, turkeys, and other animals. A facility that deals with animal slaughter byproducts is known as a rendering factory. Following that, the rendered fat and feathers are utilized as raw materials to create a variety of goods, including soap, candles, soaps, cosmetics, polymers, and even fertilizer.

If you have a rendering facility for poultry, it’s time to move on. You have the tools and knowledge to produce high-quality protein products from your leftover chicken. Using the correct procedure and tools, you may make a wide range of animal feed products with little environmental impact.

Sunrise Poultry Rendering Plant Machines is your one-stop shop for all your poultry rendering equipment needs. We provide everything you need if you want to expand an existing facility or establish your own render farm business.

Conclusion:

Sunrise is the manufacturer of poultry rendering plant is essential to the poultry industry’s push for efficiency and sustainability. These businesses are assisting the industry in meeting the rising demand for protein worldwide while having a less negative environmental impact by consistently creating cutting-edge solutions. We may anticipate even more fascinating advancements in the field of poultry rendering as technology keeps developing. The sector of animal protein, oil, nutrition, food, biotechnology, and solid waste treatment is the focus of SunRise, a complete environmental protection technology limited corporation.

Categories

Recent Posts

-

What is harmless treatment of sick and dead animals and poultry(rendering plant) A Key Initiative to Protect the Ecological Environment and Food Safety.

March 6, 2025 -

How does Sunrise rendering plant equipment destroy avian influenza viruses in livestock poultry carcasses

March 5, 2025 -

Sunrise Rendering Thailand Exhibition

March 5, 2025