Description

Buffer Bin Application

Some common applications for buffer bin include:

- Manufacturing: Within a manufacturing environment, buffer bins find utility in temporarily storing raw materials before processing, or in containing finished products prior to packaging and shipment.This practice aids in maintaining an uninterrupted material flow throughout the manufacturing process and minimizing production disruptions caused by material shortages.

- Warehousing: In a warehouse setting, buffer bins can be used to temporarily store items that are waiting to be picked or packed for shipment. This can help ensure that items are readily available for order fulfillment and reduce the risk of stockouts.

- Distribution centers: In a distribution center, buffer bins can be used to temporarily store items that are waiting to be shipped to retail locations or customers. This can help ensure that items are readily available for shipment and reduce the risk of stockouts.

- Supply Chain: Buffer bins can be used in supply chain to hold items waiting to be shipped or received, this can help keep the flow of goods steady, help reducing inventory costs and the risk of stockouts.

- Inventory management : Buffer bins can be used to create a buffer stock, which is a safety stock that is held in reserve to help protect against stockouts in the event of unexpected demand.

- Automotive : Buffer bins can be used in automotive industry for holding parts during assembly line.

What is Buffer Bin

A buffer bin is a storage area that is used to temporarily hold items before they are moved to their final destination. Its applicability extends across diverse environments, including manufacturing plants, warehouses, and distribution centers, among others.Buffer bins frequently serve the purpose of optimizing material flow within a facility, guaranteeing a consistent inventory of items accessible for production or distribution needs.They can additionally function as storage for items awaiting shipment or delivery.

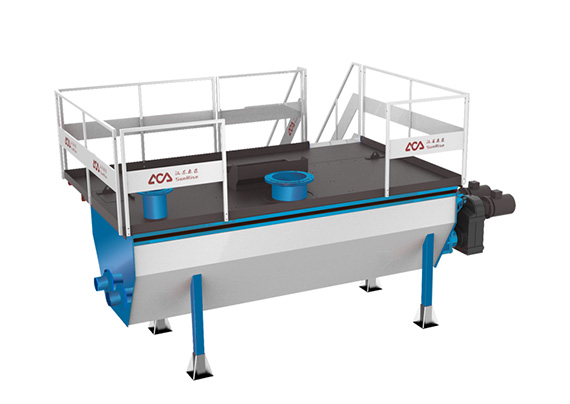

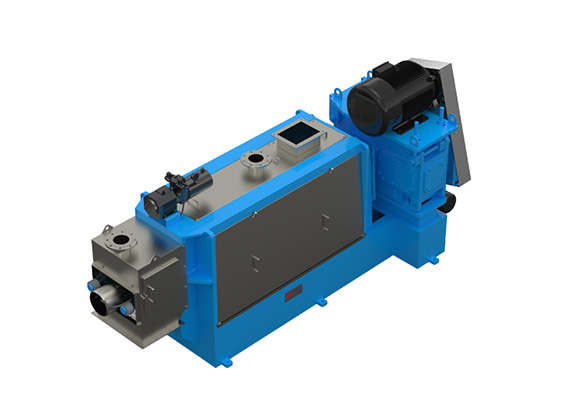

The receiving bin is used to temporarily store the materials discharged from the cooking drying tank, and convey the materials to the filter screen screw conveyor through the screw conveyor at the bottom of the receiving bin.

The receiving bin adopts the reverse spiral design, and the two ends of the blade use a closed structure. The materials are transported circularly in the bin to ensure that there is no accumulation of materials, and improve the conveying accuracy and efficiency.

The steam jacket and insulation layer are designed at the bottom of the receiving bin to maintain the temperature of the materials in it, so as to avoid solidification of materials due to temperature reduction.

Technical parameter

| Model | Volume(m³) | Power(kw) | Motor brand | Size(L*W*H)mm | Weight(kg) |

| JLC065 | 6.5 | 5.5 | Simens | 6500*1700*2050 | 4850 |

| JLC100 | 10 | 4 | Simens | 7850*1720*3350 | 7120 |

Buffer Bin FAQ

A buffer bin is a type of storage container that is used to temporarily hold materials or products in a manufacturing or assembly process.

Some common questions related to buffer bins may include:

- What types of materials can be stored in a buffer bin?

- How is the buffer bin used in a manufacturing process?

- What are the benefits of using a buffer bin?

- How does the size of the buffer bin affect its effectiveness in a manufacturing process?

- Can buffer bins be customized for specific applications?

- Are there specific safety measures that should be observed when utilizing a buffer bin?