Description

Application

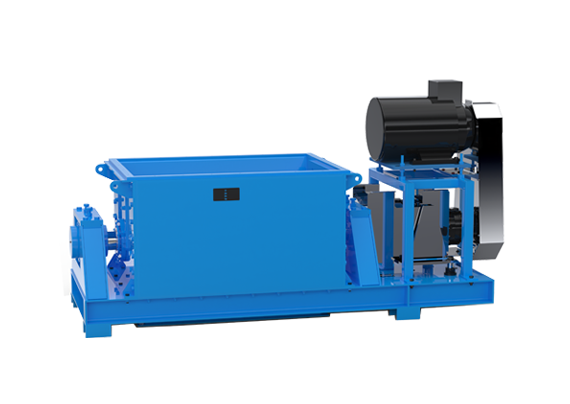

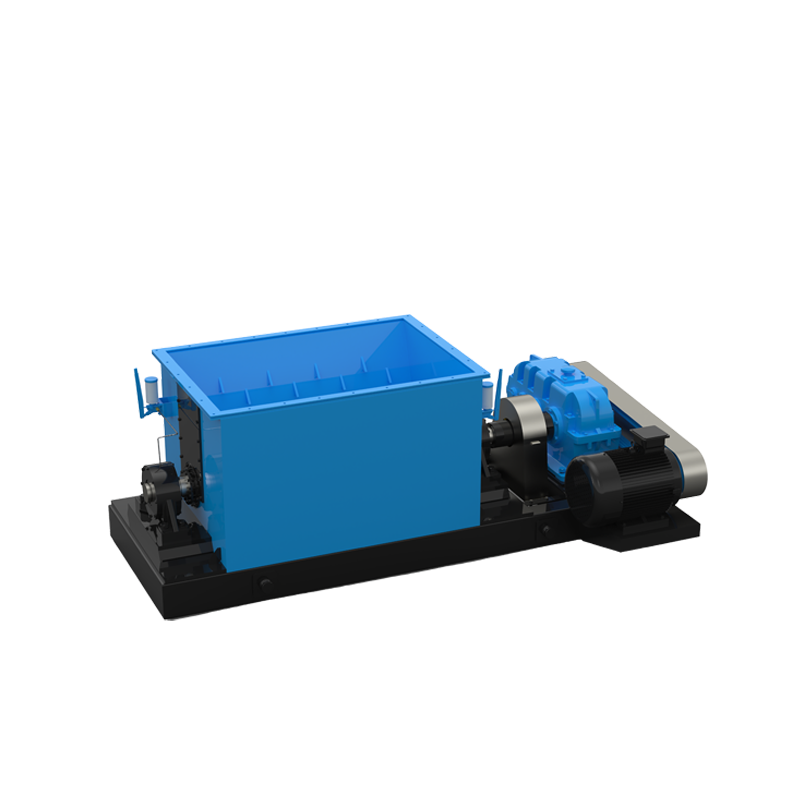

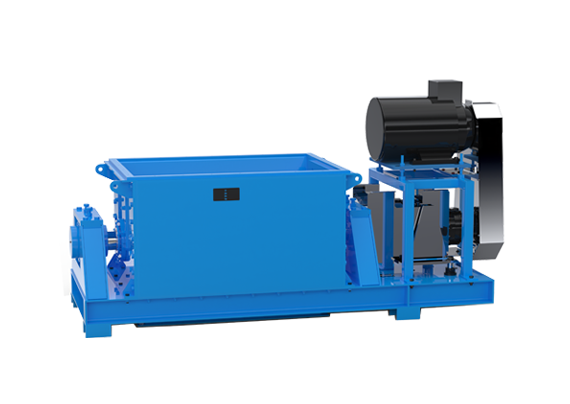

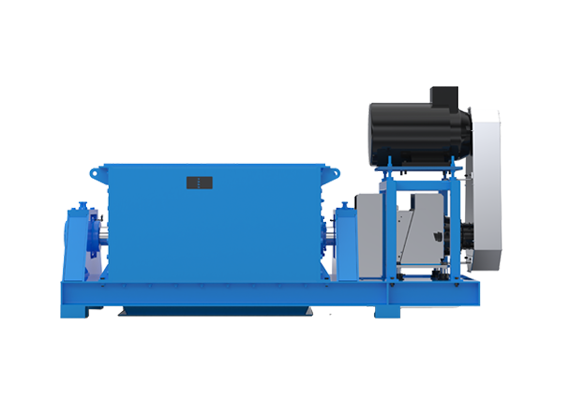

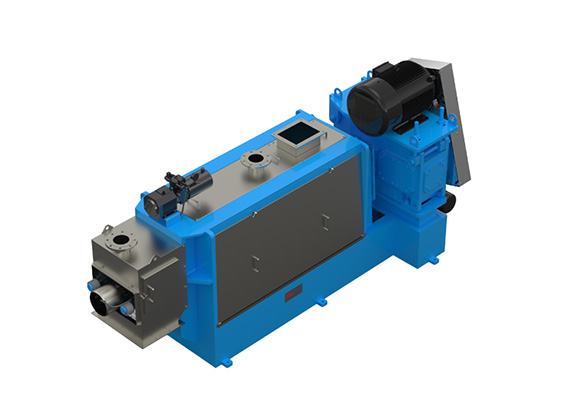

Pre-crusher is a heavy crushing machine, specially designed for animal by-product industry, before the rendering process, we can use the pre-crusher for size reduction of complete carcasses of cattle, sheep, horse and pig as well as all sorts of offal and bones from slaughterhouses.

A pre-crusher is used in various industrial and commercial applications to reduce the size of materials before they are processed further. This can include reducing the size of large solid items, breaking down pallets or crates, or compacting waste material into dense bales for easier disposal or recycling.

Design characteristics

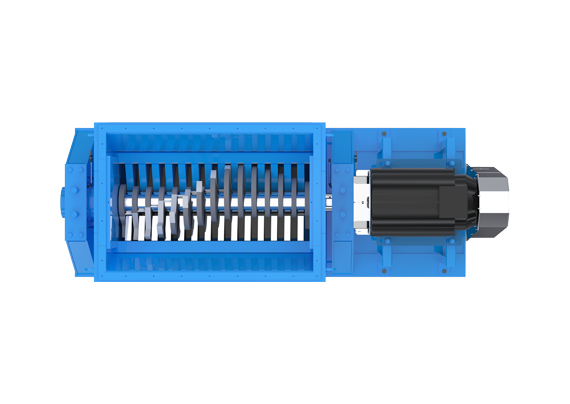

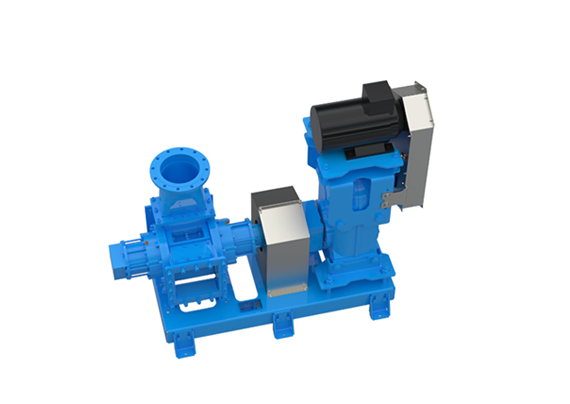

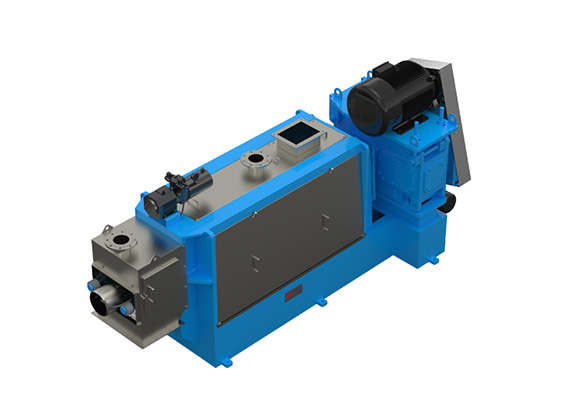

1. Rotating blade and the cutting surfaces of anvil are made surface-hardening treatment, the tool has strong wear resistance.

2. Low speed crushing shaft ensure that pre-crusher can handle metals in the raw material.

3. According to standard’s requirement, installed the electronic speed monitor on the drive device, which will

4. Instantaneously shut off the motor in case of large pieces of metal entering the pre-crusher

5. The crusher shaft is fitted into heavy-duty spherical rollers, which can resist radial and axial impacts of up to 80 tons.

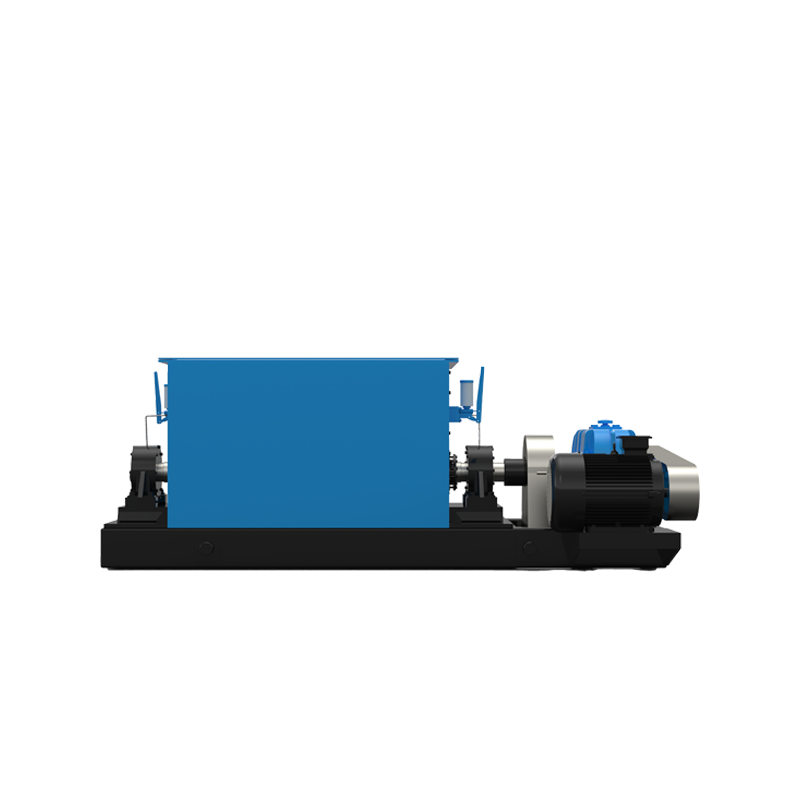

6. Transmission from motor to crusher shaft is made of standardised component parts

7. Crusher shaft main bearing houses are fitted into tapered guides, which allows quick maintenance and replacement of crusher shaft.

8. The design of crushing knife assure crush the material to maximum 48mm pieceson one side.

Technical parameters

| Model | Ability(t/h) | Power(kw) | Motor brand | Size(L*W*H)mm | Weight(kg) |

| PS-25T | 25-30 | 75 | Simens | 3835*1970*1290 | 8200 |

what is Pre-crusher / prebreaker

A pre-crusher is a machine that is used to reduce the size of materials before they are processed further. It crushes large, solid items into smaller pieces, making them easier to handle and transport. They find frequent application in sectors such as waste management, recycling, and manufacturing. Their purpose is to diminish the bulk of waste materials, enhance bale density, and ready materials for subsequent processing.

Pre-crusher FQA

Q: What is used for?

A: Prior to further processing, a pre-crusher is employed to decrease the dimensions of substantial, solid materials. This apparatus is prevalent within sectors such as waste management, recycling, and manufacturing.

Q: How does work?

A: The functionality of a pre-crusher involves exerting pressure on a material to diminish its dimensions. This procedure can be executed via either hydraulic pressure or mechanical force.

Q: What are the benefits r?

A: The benefits of using a pre-crusher include reducing the volume of waste material, increasing the density of bales for easier handling and transportation, and preparing materials for further processing.

Q: Are pre-crushers suitable for all types of materials?

A: Pre-crushers are suitable for many different types of materials, including solid waste, pallets, crates, and other large items. However, the suitability of a pre-crusher for a specific material depends on its size, composition, and other factors.

Q: How do I choose the right pre-crusher for my application?

A: For the selection of an appropriate pre-crusher that aligns with your requirements, deliberations must encompass aspects like the nature and dimensions of the materials to be processed, spatial limitations, and budgetary considerations. Engaging with a pre-crusher manufacturer or supplier is recommended to ascertain the optimal choice tailored to your needs.