Green Technology at Its Best: Receiving Bin Rendering Plant

Green Technology at Its Best: Receiving Bin Rendering Plant

The Receiving Bin Rendering Plant boasts a mature craft layout that addresses the pressing issue of exhaust gas emissions. SunRise understands that efficient and environmentally friendly production is not just a responsibility, but a shared pursuit among stakeholders. By investing in cutting-edge equipment and implementing advanced processes, they have succeeded in creating machines that set new standards in sustainability.

At the heart of the Receiving Bin Rendering Plant are various specialized equipment systems designed to ensure minimal environmental impact. Let’s explore some of the key components that make your plant a true marvel of green technology:

1. Ionization Tower: The ionization tower plays a crucial role in reducing harmful emissions. By employing ionization technology, it effectively neutralizes exhaust gases, contributing to cleaner air quality.

2. Air Washer: The air washer system further enhances the purification process. It uses water and specialized filters to remove impurities from the air, resulting in a significant reduction in pollutants.

3. Steam Condensate Return System: SunRise understands the value of resource conservation. The steam condensate return system allows for the collection and reuse of condensed steam, minimizing water consumption and energy waste.

What’s Receiving Bin Rendering Plant?

The Receiving Bin Rendering Plant is an advanced waste management system designed to efficiently process organic waste materials. It offers a comprehensive solution for transforming waste into valuable resources such as renewable energy and high-quality organic fertilizers. This state-of-the-art facility boasts a range of impressive features that contribute to its effectiveness and sustainability.

1. Efficient Waste Processing:

Equipped with advanced sorting and processing technology, the Receiving Bin Rendering Plant ensures the efficient handling of diverse waste streams. It is capable of handling a wide variety of organic waste materials, including food waste, agricultural residues, and animal by-products. The system utilizes automated processes to sort, shred, and convert waste into useful by-products, minimizing the amount of waste sent to landfills.

2. Renewable Energy Generation:

One of the key advantages of the Receiving Bin Rendering Plant is its ability to generate renewable energy. Through a process called anaerobic digestion, organic waste materials are broken down, producing biogas as a by-product. This biogas, rich in methane, can be utilized as a renewable energy source for electricity generation or as a clean fuel for heating and transportation. The plant thus contributes to reducing greenhouse gas emissions and dependence on fossil fuels.

3. Production of High-Quality Fertilizers:

In addition to renewable energy, the Receiving Bin Rendering Plant also produces nutrient-rich organic fertilizers. After the waste is processed and digested, the resulting material undergoes a composting and drying process. This yields a high-quality fertilizer that can be used in agriculture, promoting soil health and reducing the need for chemical fertilizers. By closing the nutrient cycle, the plant minimizes the environmental impact associated with conventional fertilizer production.

4. Environmental Benefits:

The implementation of the Receiving Bin Rendering Plant offers numerous environmental benefits. By diverting organic waste from landfills, it helps reduce the generation of harmful greenhouse gases, such as methane, which contribute to climate change. Moreover, the plant contributes to the preservation of land resources by minimizing the need for additional landfill sites. The generation of renewable energy and the production of organic fertilizers further contribute to a circular economy and a sustainable future.

How Does Receiving Bin Rendering Plant Work?

A receiving bin rendering plant is a state-of-the-art facility designed to process organic waste and convert it into various useful products. It serves as a crucial link in the waste management chain, contributing to the reduction of environmental impact and the generation of valuable resources. These plants are equipped with advanced technology and engineered to handle large volumes of waste efficiently.

1: The Input: Waste Collection and Receiving Bins

The first step in the process involves waste collection from various sources such as slaughterhouses, meat processing facilities, supermarkets, and restaurants. The waste is carefully sorted to ensure that only suitable materials are sent for rendering. Receiving bins, designed to handle the specific waste streams, are used to store and transport the waste to the rendering plant. These bins are manufactured by companies like SunRise, who specialize in producing robust and reliable containers capable of withstanding the demands of waste management operations.

2: The Transformation Process Begins

Once the waste reaches the receiving bin rendering plant, the transformation process commences. The waste is unloaded from the receiving bins and conveyed to the initial processing area. Here, it undergoes further sorting and screening to remove any contaminants or non-organic materials. The waste is then shredded or ground into smaller particles to enhance the efficiency of subsequent processes.

3: Rendering and Separation

The shredded waste enters the rendering system, where it is subjected to high temperatures through a process known as rendering. During rendering, fats and oils are separated from the solid materials. The heat effectively breaks down the organic matter, transforming it into its basic components. The fats and oils collected during this process are valuable and find applications in various industries, including animal feed, biodiesel production, and cosmetics.

4: Further Processing and Product Generation

The solid material that remains after rendering is referred to as “meal.” This meal undergoes further processing, including drying and grinding, to produce a nutrient-rich substance called “protein meal.” Protein meal has extensive applications in animal feed, also providing essential nutrients and promoting animal health.

5: Waste Minimization and Environmental Benefits

Receiving bin-rendering plants play a pivotal role in waste minimization and environmental conservation. By diverting organic waste from landfills, these facilities reduce greenhouse gas emissions and minimize the strain on limited landfill capacities. Additionally, the by-products generated, such as fats, oils, and protein meals, find valuable applications across various industries, and also contributing to a more sustainable and circular economy.

Conclusion

SunRise, a renowned leader in sustainable technologies, has taken the initiative to tackle waste management with its cutting-edge Receiving Bin Rendering Plant. With a focus on environmental responsibility and also resource optimization, SunRise has earned a reputation for delivering innovative solutions that help combat the global waste crisis. The Receiving Bin Rendering Plant Machine is a prime example of its commitment to creating a greener future.

Categories

Recent Posts

-

What is harmless treatment of sick and dead animals and poultry(rendering plant) A Key Initiative to Protect the Ecological Environment and Food Safety.

March 6, 2025 -

How does Sunrise rendering plant equipment destroy avian influenza viruses in livestock poultry carcasses

March 5, 2025 -

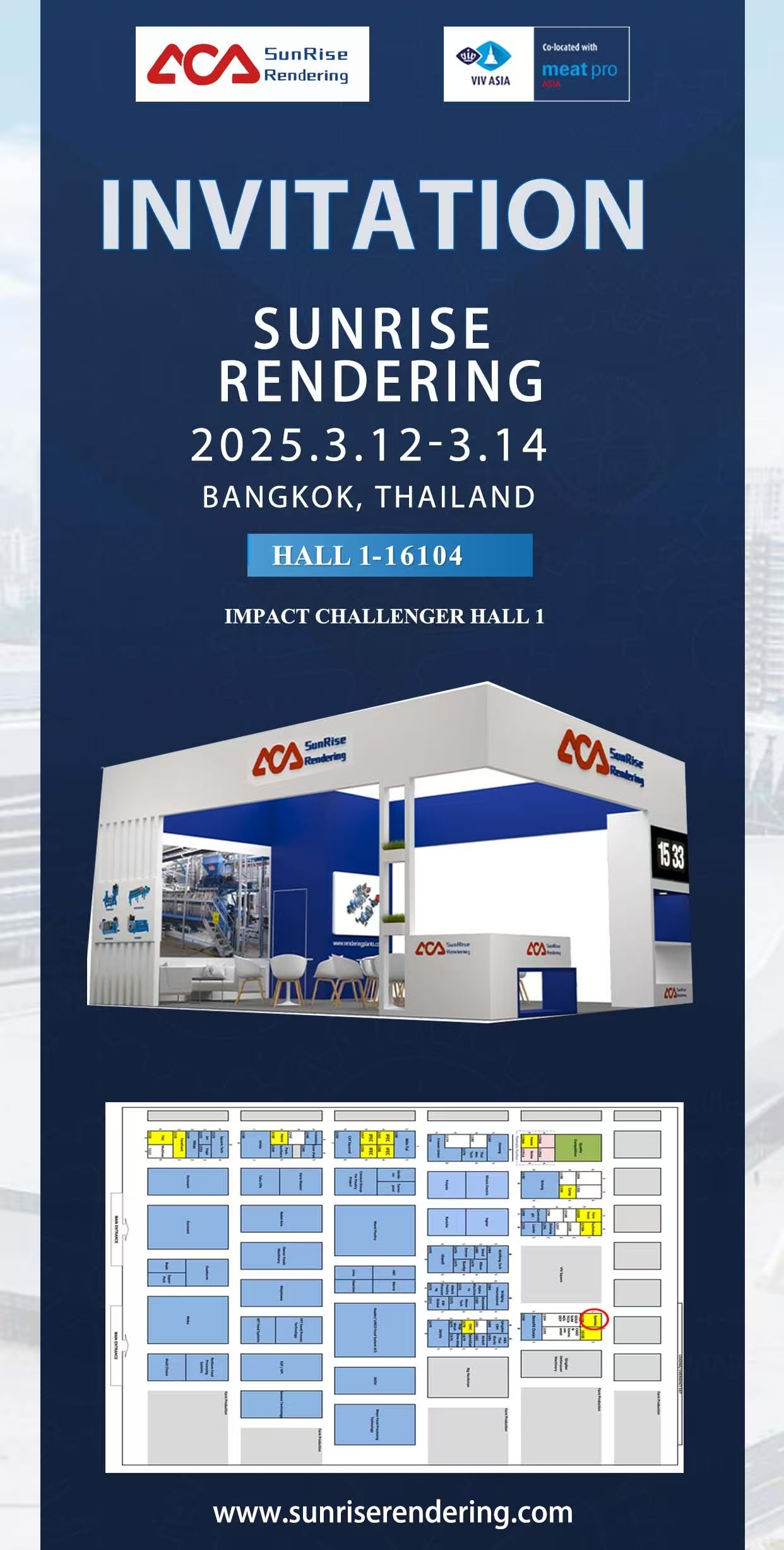

Sunrise Rendering Thailand Exhibition

March 5, 2025