Rendering Plant Equipment: Best Practices and Operational Insights

In the world of rendering plants, where animal by-products are transformed into valuable commodities, operational efficiency plays a pivotal role in ensuring profitability and sustainability. To achieve optimal performance, it is crucial for rendering plant operators to employ best practices, leverage cutting-edge equipment, and streamline their workflows. In this blog, we will explore key insights and strategies for maximizing productivity in rendering plants, with a particular focus on the high-quality equipment provided by Jiangsu Sunrise Environmental Protection Technology Co. Ltd.

1. Streamlining Workflow for Enhanced Efficiency:

Efficient workflow management is the backbone of any successful rendering plant operation. By implementing effective strategies, operators can significantly reduce downtime, improve resource allocation, and increase overall productivity. One essential practice is to establish clearly defined processes and standard operating procedures (SOPs) for each stage of rendering, from raw material handling to final product distribution. Automated systems and integrated software solutions offered by manufacturers like Jiangsu Sunrise can further streamline operations, enhancing efficiency and minimizing errors.

2. Selecting the Right Equipment for Optimal Performance:

Choosing the appropriate rendering plant equipment is crucial for maximizing efficiency. Manufacturers like Jiangsu Sunrise offer a wide range of high-quality machinery designed to meet the specific needs of rendering plants. Key equipment includes rendering cookers, screw presses, drying systems, and odor control systems. These advanced technologies enable operators to process raw materials effectively, separate fats and proteins, and minimize environmental impact through odor reduction. Investing in reliable equipment ensures smooth operations and long-term cost savings.

3. Prioritizing Safety and Compliance:

Safety should always be a top priority in rendering plants, as they involve handling potentially hazardous materials. Adhering to strict safety protocols and regulations not only protects the well-being of workers but also safeguards the environment and public health. Equipment manufacturers like Jiangsu Sunrise prioritize safety in their designs, incorporating features such as emergency stop buttons, safety interlocks, and easy-to-clean surfaces. Regular maintenance and employee training programs further promote a safe and compliant work environment.

4. Leveraging Technology for Data-Driven Decision Making:

In today’s digital age, data-driven decision making is becoming increasingly vital for operational success. Manufacturers such as Jiangsu Sunrise offer equipment integrated with advanced control systems and data collection capabilities. By leveraging real-time data on energy consumption, production rates, and equipment performance, operators can identify bottlenecks, track efficiency metrics, and make informed decisions to optimize their rendering processes. This technology empowers operators to continuously improve their operations and achieve higher levels of productivity.

5. Embracing Sustainability and Environmental Responsibility:

Rendering plants have a significant impact on the environment, and adopting sustainable practices is essential for long-term viability. Equipment manufacturers like Jiangsu Sunrise prioritize sustainability by developing energy-efficient machinery, incorporating waste heat recovery systems, and implementing odor control technologies. Additionally, rendering plants can explore partnerships with renewable energy providers, invest in green packaging solutions, and promote responsible waste management practices to minimize their ecological footprint.

Domestic Project: Shuanghui Group’s Rendering Success

Rendering plants play a crucial role in transforming animal by-products into valuable resources such as proteins, fats, and other materials. To achieve efficient and sustainable rendering processes, state-of-the-art equipment is essential.

Under the leadership of Shuanghui Group, a prominent player in the meat processing industry, a rendering plant in Luohe City, Henan province, has set a remarkable example. Since its establishment in February 2015, the plant has demonstrated impressive capabilities, processing approximately 200 thousand birds’ chicken feathers and 10 tons of dead chicken per day.

Rendering plant equipment played a pivotal role in Shuanghui Group’s success story. Jiangsu Sunrise Environmental Protection Technology Co. Ltd provided cutting-edge machinery that ensured high-quality rendering processes. The equipment’s efficiency and reliability allowed Shuanghui Group to meet its production targets while maintaining stringent quality standards.

1. High-Capacity Rendering Equipment: Enhancing Efficiency

Jiangsu Sunrise’s rendering equipment excels in handling large volumes of animal by-products. Their cutting-edge machinery, such as rendering cookers, press dewatering machines, and continuous hydrolysis equipment, optimizes the rendering process, ensuring maximum efficiency and productivity. With the ability to process significant quantities of raw materials, Shuanghui Group’s rendering plant achieved exceptional throughput rates and minimized downtime.

2. Advanced Waste Heat Utilization: Promoting Sustainability

Rendering plants often generate substantial amounts of waste heat. To address this challenge, Jiangsu Sunrise offers advanced waste heat utilization systems. By harnessing this excess heat, it can be converted into useful energy for various applications within the rendering plant. This energy-efficient approach not only reduces environmental impact but also lowers operational costs, making rendering processes more sustainable and economically viable.

Global Cooperation: Extending Expertise Worldwide

Through global cooperation and partnerships with renowned companies, Jiangsu Sunrise continues to extend its expertise and cutting-edge solutions to rendering projects worldwide. As the rendering industry evolves, the role of advanced equipment becomes increasingly vital, ensuring sustainable and efficient processes that maximize the value of animal by-products while minimizing environmental impact.

Jiangsu Sunrise Environmental Protection Technology Co. Ltd has also established fruitful partnerships with international companies such as AGROSUPER, DLG, Leong HUP, and CP Group. These collaborations have paved the way for the global adoption of advanced rendering equipment and the formulation of exclusive solutions tailored to the specific needs of each partner.

By providing excellent rendering plant equipment, Jiangsu Sunrise has contributed to the success and growth of its global partners. The company’s expertise and commitment to delivering innovative solutions have earned them a stellar reputation in the rendering industry worldwide.

Conclusion:

Efficiency and operational excellence are key to the success of rendering plants. By implementing best practices, leveraging cutting-edge equipment from manufacturers like Jiangsu Sunrise, and embracing sustainable approaches, operators can enhance productivity, reduce costs, and ensure the long-term viability of their operations. By staying updated with the latest industry trends and continuously optimizing their workflows, rendering plant operators can drive success in a competitive marketplace while minimizing their impact on the environment.

Categories

Recent Posts

-

What is harmless treatment of sick and dead animals and poultry(rendering plant) A Key Initiative to Protect the Ecological Environment and Food Safety.

March 6, 2025 -

How does Sunrise rendering plant equipment destroy avian influenza viruses in livestock poultry carcasses

March 5, 2025 -

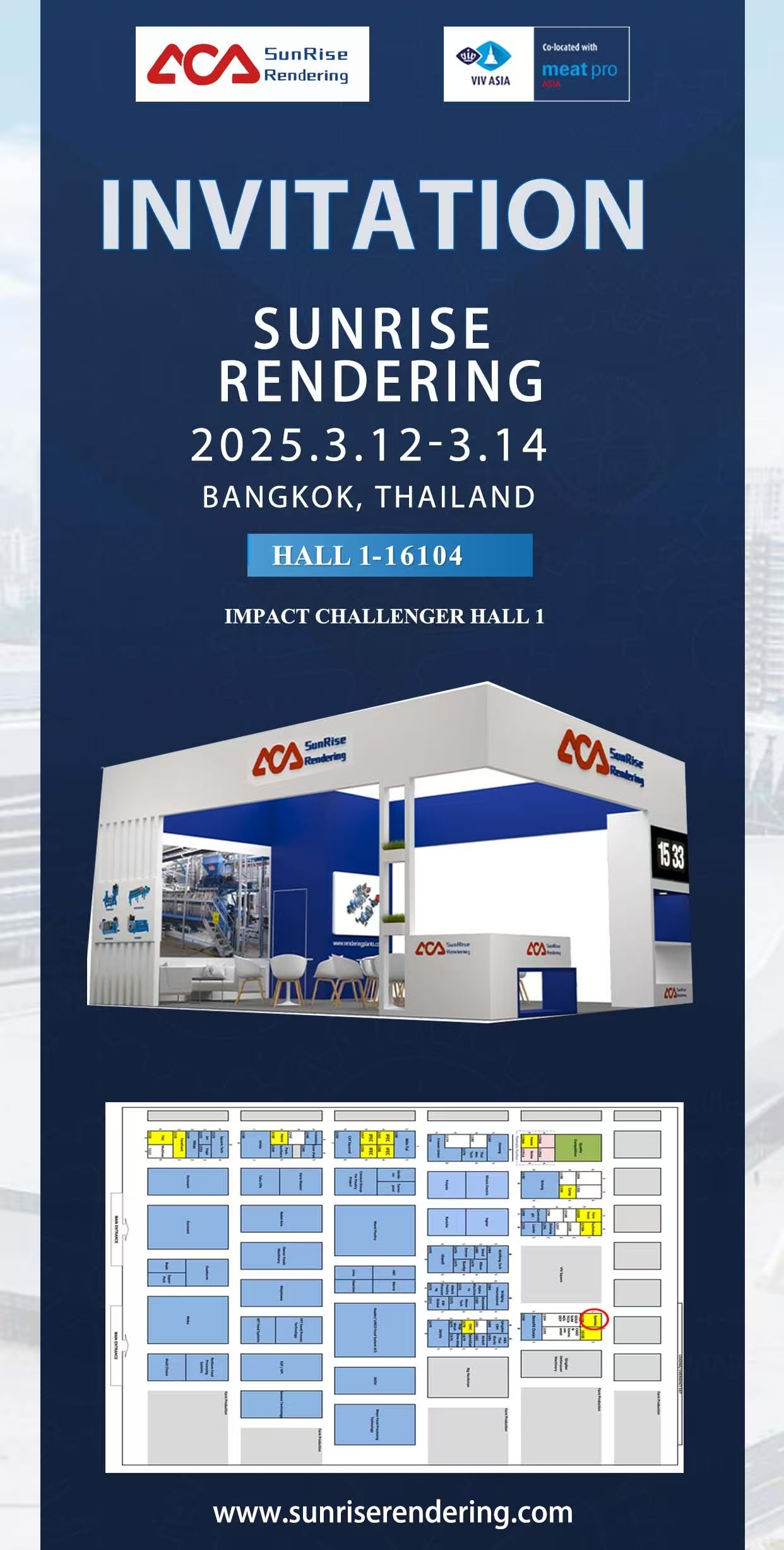

Sunrise Rendering Thailand Exhibition

March 5, 2025