Choosing Optimal Rendering Plant Location: Strategic Guide by SunRise

Choosing Optimal Rendering Plant Location: Strategic Guide by SunRise

Selecting the Optimal Rendering Plant Location is a critical decision that significantly impacts the operational efficiency, cost-effectiveness, and environmental impact of the facility. SunRise, a leading manufacturer in the rendering industry, understands the importance of a well-placed rendering plant. In this blog post, we will delve into the key factors to consider when choosing rendering plant locations.

Environmental Factors

1. Proximity to Raw Material Sources

One of the primary considerations when siting a rendering plant is its proximity to raw material sources, such as slaughterhouses, meat processing facilities, and food manufacturers. A location within a reasonable distance from these sources minimizes transportation costs and reduces the environmental impact associated with long-distance hauling.

2. Zoning and Regulatory Compliance

Environmental regulations play a vital role in determining suitable plant locations. SunRise recommends choosing areas zoned for industrial use, ensuring compliance with local, state, and federal regulations. This helps mitigate potential conflicts with neighboring communities and reduces the risk of legal issues.

Logistical Considerations

1. Transportation Infrastructure

Efficient transportation infrastructure is crucial for both incoming raw materials and outgoing finished products. Opt for Optimal Rendering Plant Location with well-developed road, rail, and, if applicable, waterway systems. Easy access to major highways and distribution centers can streamline the movement of goods.

2. Access to Labor Pool

A skilled and available workforce is essential for the plant’s smooth operation. Consider areas with a qualified labor pool experienced in rendering operations or similar industries. Proximity to educational institutions offering relevant programs can help ensure a steady supply of skilled workers.

Economic Factors

1. Land and Real Estate Costs

Land and real estate costs vary greatly depending on location. Balancing cost considerations with other factors is crucial. While it’s tempting to choose a low-cost location, a compromise that maintains efficiency and accessibility must be struck.

2. Energy Costs and Availability

Rendering plants are energy-intensive facilities. Analyze the availability of reliable and affordable energy sources in potential locations. Proximity to energy infrastructure and renewable energy sources can lead to substantial cost savings over time.

Community and Public Relations

1. Community Acceptance

Maintaining positive relations with the local community is essential. Engage with community stakeholders to address concerns, communicate your commitment to sustainable practices, and contribute positively to the local economy.

2. Aesthetic and Odor Concerns

Rendering plants can generate odors that may affect neighboring areas. SunRise recommends investing in advanced odor control technologies and selecting locations where potential odor impact can be minimized. Proper site design and landscaping can further mitigate these concerns.

Future Growth and Expansion

1. Scalability

Choose a location that allows for future expansion and scalability. Anticipate the need for increased capacity and ensure that the chosen site can accommodate these developments without significant disruptions.

2. Market Access

Consider the proximity to target markets for rendered products. A location close to major consumers can reduce transportation costs and increase competitiveness in the market.

Maximizing Efficiency: Configuring Machines in SunRise Rendering Plant Locations

1. Layout Planning for Seamless Workflow

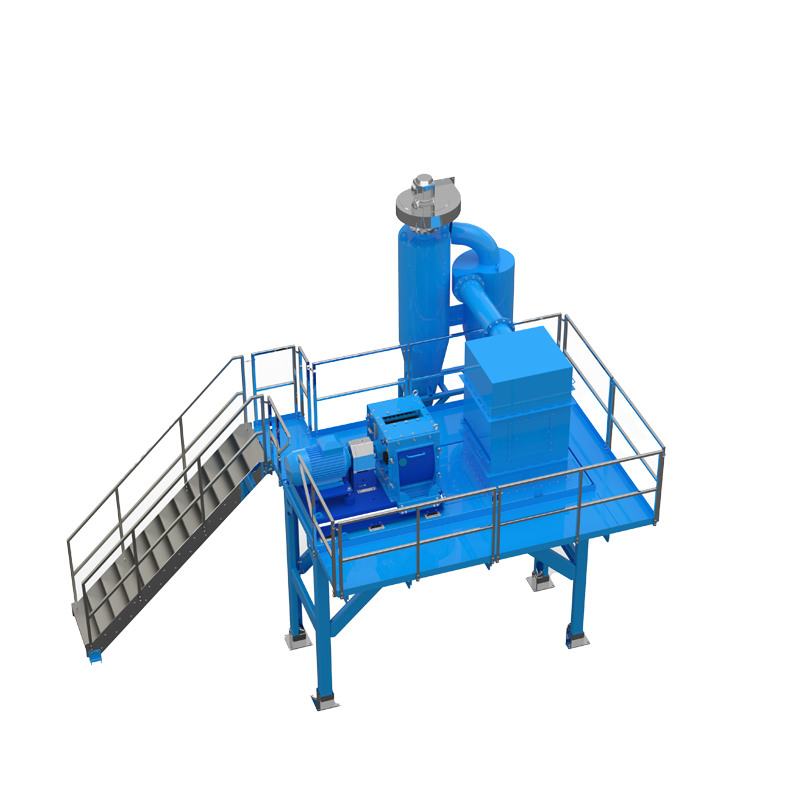

Effective layout planning is the foundation of a well-organized rendering plant. The layout should prioritize a seamless workflow, minimizing the movement of materials and reducing bottlenecks. SunRise rendering plant locations adhere to this principle by arranging machines in a logical sequence. Raw material reception, grinding, cooking, pressing, and refining processes are systematically placed to minimize the distance and time taken to transfer materials between different stages.

2. Optimal Machine Placement

Once the layout is established, placing machines optimally is the next critical step. SunRise rendering plants feature machines that are strategically positioned to reduce the need for excessive material handling. For instance, placing the grinder adjacent to the raw material reception area eliminates the need for intermediate storage, reducing the risk of contamination and preserving material quality.

3. Streamlined Processing with Automated Systems

Automation has revolutionized the rendering industry, enhancing productivity and reducing labor costs. SunRise rendering plant locations integrate automated systems to control and monitor various processes. Automated conveyors transport materials between machines seamlessly, maintaining a continuous flow without human intervention. This reduces processing time and ensures consistent quality.

4. Efficient Heat Recovery and Energy Management

Rendering processes often require high temperatures for cooking and sterilization. SunRise rendering plants incorporate advanced heat recovery systems that capture and reuse the heat generated during these processes. By doing so, these plants significantly reduce energy consumption and operating costs. Moreover, SunRise’s machines are designed to be energy-efficient, contributing to a more sustainable operation.

5. Versatile Machinery for Multiple Processes

Flexibility is crucial in rendering plants that handle a variety of raw materials. SunRise offers a range of versatile machines capable of handling different materials and processes. These machines can be configured with different settings to optimize processing parameters for each specific material, ensuring optimal resource extraction.

6. Embracing Innovation: Smart Sensors and Data Analytics

SunRise rendering plant locations embrace the power of data through smart sensors and analytics. These sensors monitor crucial parameters such as temperature, pressure, and quality metrics in real time. The collected data is then analyzed to identify trends and patterns, enabling predictive maintenance and process optimization. This proactive approach minimizes downtime and maximizes overall efficiency.

7. Ensuring Hygiene and Compliance

Rendering plants must adhere to strict hygiene standards and regulatory compliance. SunRise machines are designed with easy cleaning and maintenance in mind. Smooth surfaces and accessible components make thorough cleaning feasible, reducing the risk of cross-contamination and ensuring the end products meet quality standards.

8. Continuous Training and Support

Effective machine configuration is not a one-time endeavor; it requires continuous training and support. SunRise provides comprehensive training to plant personnel to operate and maintain their machines efficiently. Additionally, their support teams are readily available to address any issues or concerns that may arise during the plant’s operation.

Conclusion

Selecting the Optimal Rendering Plant Location is a multifaceted process that requires careful consideration of environmental, logistical, economic, community, and future-oriented factors. By taking into account SunRise’s recommendations outlined in this guide, you can ensure that your rendering plant is strategically positioned for efficiency, sustainability, and long-term success in the industry. Remember, a well-chosen location is the foundation upon which a thriving rendering plant is built.

Categories

Recent Posts

-

From slaughtered chickens to treasure: Sunrise slaughter waste equipment leads the way to high-value utilization

June 11, 2025 -

Slaughter waste – what can feathers do – animal protein conversion

May 13, 2025 -

SUNRISE makes another appearance at the Saudi Poultry Expo (MEP) using Chinese intelligent manufacturing to support Saudi Arabia’s 2030 green vision

April 19, 2025