Transforming Waste into Value: SunRise – The Leading Rendering Plant Manufacturer

Transforming Waste into Value: SunRise – The Leading Rendering Plant Manufacturer

In a world grappling with environmental challenges, finding sustainable solutions to waste management is crucial. Rendering plants play a vital role in transforming organic waste into valuable resources. SunRise, a pioneering rendering plant manufacturer, has emerged as an industry leader, providing innovative and efficient solutions that not only address waste management concerns but also create economic opportunities.

Sunrise’s Partners and Their Challenges: Rendering Plant Manufacturer

SunRise’s rendering plants primarily cater to the needs of various industries, including agriculture, food processing, and animal by-product management. Sunrise’s partners consist of farmers, livestock producers, slaughterhouses, meat processors, and waste management companies. These stakeholders face several challenges related to waste disposal, environmental regulations, and the economic viability of their operations.

1. Farmers and Livestock Producers:

These individuals face the daunting task of managing animal by-products, such as carcasses, feathers, and bones. Improper disposal of these materials can lead to pollution, disease transmission, and legal repercussions. Moreover, the rising costs associated with waste management and environmental compliance put financial strain on farmers and livestock producers.

2. Slaughterhouses and Meat Processors:

These facilities generate significant amounts of by-products, including blood, fat, and offal, which need to be handled efficiently. Complying with stringent regulations and maintaining hygiene standards are critical to their operations. Moreover, finding economically viable ways to manage waste is essential for their profitability.

3. Waste Management Companies:

As waste management becomes a global concern, waste management companies are increasingly seeking sustainable solutions. They face the challenge of handling diverse organic waste streams and ensuring compliance with environmental standards. Finding efficient and cost-effective methods for waste treatment and disposal is crucial for their success.

SunRise’s Solutions: Leading Rendering Plant Manufacturer

SunRise offers a range of cutting-edge rendering plants that address the specific needs and challenges faced by their target audience. Here are the key features and benefits of their products:

1. Advanced Rendering Technology:

SunRise leverages advanced rendering technology to efficiently process organic waste. Their plants employ processes such as grinding, cooking, separation, and drying, resulting in high-quality end products such as animal feed, biofuels, and organic fertilizers. This technology ensures optimal resource utilization while minimizing waste and pollution.

2. Customizable Solutions:

Understanding the diverse requirements of their target audience, SunRise offers customizable rendering plant solutions. Whether it’s a small-scale farm or a large-scale industrial facility, SunRise can tailor their plants to meet specific needs, ensuring maximum efficiency and operational effectiveness.

3. Compliance with Environmental Regulations:

SunRise rendering plants are designed to meet stringent environmental regulations. By adopting environmentally friendly practices, such as odor control systems, energy-efficient processes, and water treatment mechanisms, SunRise enables its customers to meet regulatory standards while minimizing their environmental footprint.

4. Economic Viability and Revenue Generation:

SunRise’s rendering plants not only offer sustainable waste management solutions but also create revenue streams for their customers. The by-products generated through the rendering process, such as animal feed and biofuels, can be sold or utilized within their own operations, contributing to their financial sustainability.

Rendering Plant Manufacturer: Fat Screw Press

The Fat Screw Press manufactured by SunRise is specifically designed for continuous mechanical extraction of fat, ensuring high yields and consistent results. Its simple yet effective design not only guarantees excellent performance but also reduces maintenance costs, making it an attractive choice for businesses seeking long-term efficiency.

One of the key advantages of the Fat Screw Press is its versatility in applications. It can be used for various purposes, including oil extraction from oilseeds such as soybeans, peanuts, sunflower seeds, and canola. Additionally, it proves highly effective in processing industrial and food waste, including sludge and wastewater treatment, as well as fruit juice production. Furthermore, the Fat Screw Press is adept at biomass processing, allowing the conversion of plant-based materials like palm kernel shells or rice husks into biofuels.

The design characteristics of the Fat Screw Press contribute to its exceptional performance. Equipped with a standard industrial gearbox, it ensures reliable and efficient operation. The T-type screw press features a short shaft and is equipped with a hydraulic choke tube at the outlet end. This choke tube enables the regulation of pressure manually or automatically, thus maintaining a certain level of pressure throughout the processing. By adjusting the screw press, it becomes possible to increase the capacity of the screw conveyor and ensure the stability of both the tallow and the pressed cake quality. This flexibility proves valuable when rendering plants need to handle different raw materials or varying feeding quantities.

Rendering Plant Manufacturer: Meal Cooler

Rendering plants play a crucial role in the efficient utilization of animal by-products and waste materials, transforming them into valuable resources. Among the various components of a rendering plant, the meal cooler holds significant importance. Designed to cool the product after the drying process, the Jiangsu Sunrise meal cooler, manufactured by SunRise, is a remarkable solution that ensures optimal cooling and preservation of the rendered meal.

The meal cooler manufactured by SunRise exhibits several design characteristics that make it an efficient and reliable solution for rendering plants. With its simple and sturdy construction, this cooler consists of a few components and wearing parts, reducing the risk of breakdowns and minimizing maintenance requirements. Such reliability is essential in the rendering industry, where uninterrupted processing is crucial.

Functioning as a continuously working machine, the meal cooler employs a cooling principle based on the counter flow of cooling air and the hot product. This principle ensures that the product is exposed to the coldest air as it progresses through the cooler, resulting in efficient and effective cooling. The meal cooler’s design includes a stator and a rotor, both made of mild steel, which guarantees durability and longevity.

Conclusion

SunRise understands that different clients have unique requirements when it comes to rendering plants. With a customer-centric approach, the company offers customized solutions that cater to the specific needs of each client. Whether it’s a small-scale rendering plant for a local farm or a large-scale facility for a meat processing company, SunRise’s team of experts collaborates closely with clients to design and manufacture rendering plants that maximize efficiency and minimize waste.

Categories

Recent Posts

-

What is harmless treatment of sick and dead animals and poultry(rendering plant) A Key Initiative to Protect the Ecological Environment and Food Safety.

March 6, 2025 -

How does Sunrise rendering plant equipment destroy avian influenza viruses in livestock poultry carcasses

March 5, 2025 -

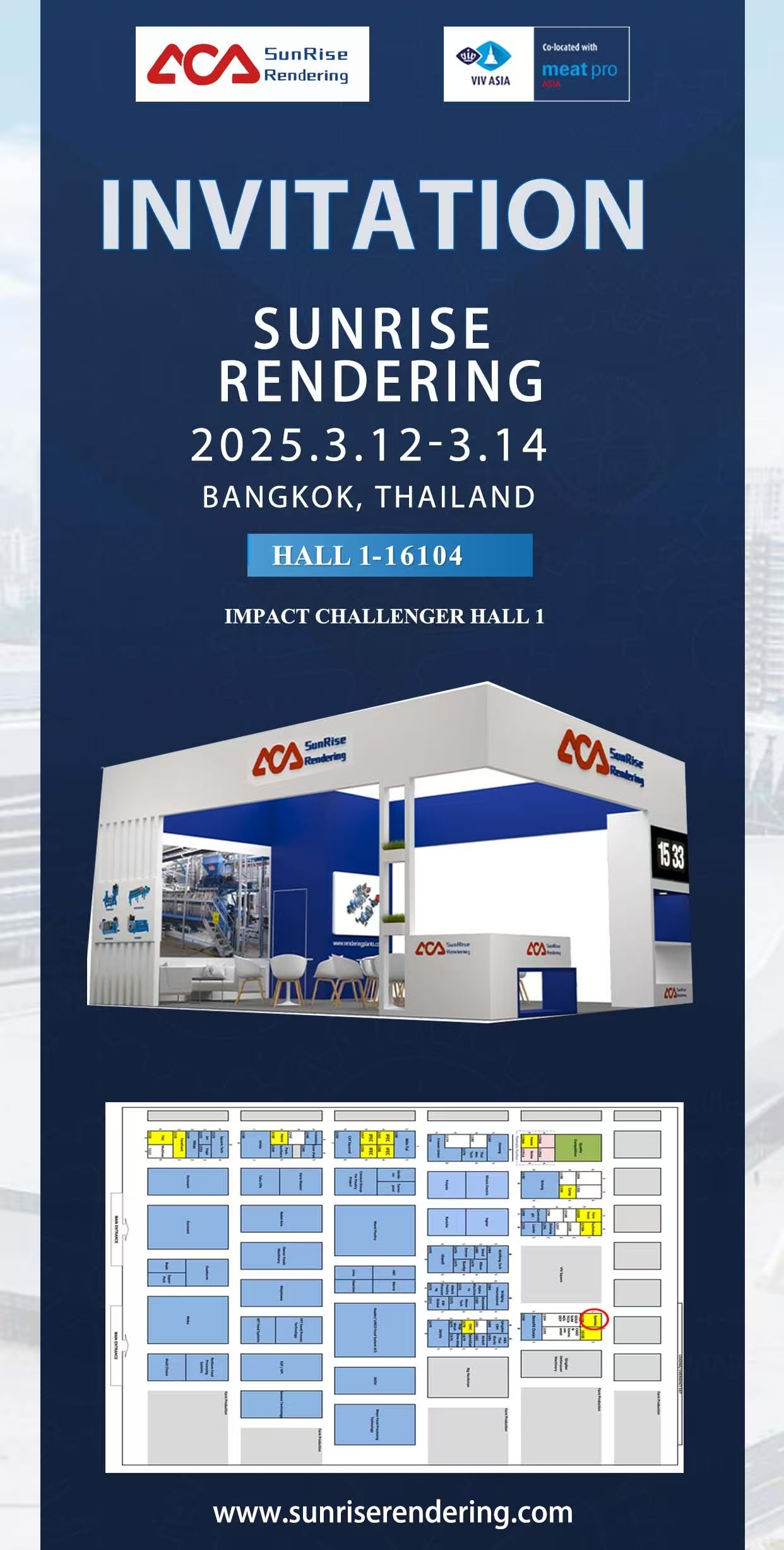

Sunrise Rendering Thailand Exhibition

March 5, 2025