Rendering plant of meat and bone meal production equipment: creating an environmentally friendly and efficient solution for the farming industry

Rendering plant of meat and bone meal production equipment: creating an environmentally friendly and efficient solution for the farming industry

Senrong environmental protection slaughter waste harmless treatment meat and bone meal production equipment, using advanced technology, optimizes the resource recovery and waste treatment in the breeding industry, not only can effectively solve the problem of animal waste, but also provide environmentally friendly and efficient production solutions for the breeding industry, to promote the development of green breeding industry.

In today’s society, with the rapid development of the farming industry, slaughter waste treatment has become an extremely difficult problem to be solved. Especially in the process of waste treatment, how to ensure that the waste is harmless treatment, not only is the industry’s environmental requirements, but also the key to the sustainable development of the breeding industry. Harmless treatment of meat and bone meal production equipment came into being, become an important technical means to solve this problem.

Harmless treatment meat and bone meal production equipment is an advanced production system integrating waste treatment, resource recovery and environmental protection functions. It is mainly used for the effective treatment and transformation of animal wastes, such as chicken bones, pig bones, etc. Through advanced high temperature and high pressure technology, these wastes are transformed into safe and harmless meat and bone meal for the use of farming and pet food industries. With the deepening of the concept of green farming, the adoption of harmless treatment equipment has become an inevitable trend in the development of the industry.

High efficiency and environmental protection: promote green farming industry

Ltd. harmless treatment of meat and bone meal production equipment is characterized by high efficiency and environmental protection. In the treatment process, the equipment through high temperature sterilization, high pressure disinfection and other technical means, can effectively kill bacteria and pathogenic microorganisms in the waste, to ensure that the production of meat and bone meal in line with national and international health standards. This equipment can make full use of the waste resources, will not be able to use the bones, organs and other parts of the animal into valuable meat and bone meal, to avoid the pollution of these wastes on the environment.

For the farming industry, waste treatment is a costly and technically demanding task. Traditional treatment methods often require a lot of labor and material resources, and improper treatment may also bring environmental hazards. The slaughter waste harmless treatment of meat and bone meal production equipment through automation and intelligent technology, simplify the treatment process, greatly reduce production costs and improve the utilization of resources. With the continuous innovation of equipment technology, the processing capacity and working efficiency of the equipment are constantly improving, and it has been able to meet the needs of large-scale farms.

Safe and efficient meat and bone meal production process

One of the core technologies of meat and bone meal production equipment for harmless treatment of slaughter waste is the high temperature and high pressure sterilization system. The production process of meat and bone meal begins with the crushing of raw materials such as waste animal bones and offal, which are refined into smaller particles by a crusher. Then, these particles are sent into the high temperature sterilization machine for high pressure cooking, the cooking process can effectively eliminate the germs and harmful substances, to ensure that the processed meat and bone meal meets the food grade hygiene standards.

The high efficiency filtration system of the equipment also plays an important role. After high temperature sterilization, the equipment will carry out further fine filtration to remove excess impurities and oil, and finally get pure, high quality meat and bone meal. This series of precise process steps ensures the quality and safety of meat and bone meal, which makes it widely used in all kinds of farming and pet food fields.

Wide range of application, broad market prospects

Jiangsu Senrong Environmental Protection Technology Co., Ltd. slaughter waste harmless treatment of meat and bone meal production equipment not only has an important application value in the breeding industry, its market prospects are also very broad. With the improvement of people’s awareness of environmental protection, more and more countries and regions have put forward more stringent environmental requirements for the treatment of waste. Harmless treatment of meat and bone meal production equipment just to meet this trend, its environmental protection, high efficiency, intelligent features make it become one of the indispensable equipment in the farming industry.

In the new era, with the advancement of agricultural modernization, the farming industry is gradually developing in the direction of scale and intensification. The rise of large-scale farms has brought about a more massive demand for waste treatment. The emergence of slaughter waste harmless treatment meat and bone meal production equipment is the key to solving this problem. Its advanced technology can not only meet the waste treatment needs of farms, but also through the production of meat and bone meal, the original unavailable resources into valuable by-products, helping the farming industry to achieve resource recycling and sustainable development.

Reduce operating costs and improve farming efficiency

The application of meat and bone meal production equipment for the harmless treatment of slaughter waste can not only effectively solve the problem of breeding waste treatment, but also bring obvious economic benefits for farming enterprises. Through the recovery and transformation of waste, farming enterprises can reduce the cost of waste treatment. Traditional treatment often requires employing a large number of laborers for sorting and processing, while environmentally friendly treatment equipment reduces labor costs and management costs through automated systems.

Meat and bone meal has a high market value as an important feed ingredient. By transforming waste into meat and bone meal through environmentally friendly treatment equipment, farming enterprises can not only realize the harmless treatment of waste, but also gain additional income through the sale of meat and bone meal. Especially in the current feed market demand continues to grow in the background, meat and bone meal as a high-protein feed ingredients, the market outlook is very broad.

Technological innovation, leading the development of the industry

The successful application of meat and bone meal production equipment for the harmless treatment of slaughter waste not only relies on advanced treatment technology, but also inseparable from the continuous technological innovation. With the continuous development of science and technology, the technology of production equipment is also constantly upgraded. For example, in recent years, some high-efficiency pyrolysis technology and biological enzyme technology have been introduced into the production process of meat and bone meal, and these innovative technologies have greatly improved the efficiency of waste treatment and further lowered the treatment cost.

In the future, as the farming industry’s requirements for environmental protection and resource recycling are getting higher and higher, the industry’s demand for harmless treatment of meat and bone meal production equipment will show explosive growth. Enterprises that can be at the forefront of technological innovation and intelligent management of equipment will be able to occupy the market high point, leading the industry’s direction of development.

Safety and environmental protection is the core of future development

In the future development of slaughter waste harmless treatment meat and bone meal production equipment, safety and environmental protection will continue to be the core issue. With the continuous improvement of global environmental standards, the environmental pressure on the farming industry is also increasing. Harmless slaughter waste treatment equipment must continue to carry out technological upgrades to ensure that in the efficient treatment of waste can do zero emissions, low energy consumption, low pollution. Only in this way can we truly realize the green development of the farming industry and promote the whole industry to a more sustainable and environmentally friendly direction.

With the continuous progress of digital technology, intelligence will become an important trend in the future development of slaughter waste treatment equipment. Intelligent equipment is not only able to monitor the treatment process in real time, but also able to automatically adjust according to different production needs, thus improving production efficiency and safety. The introduction of intelligent management system will also further reduce the operating costs of enterprises and improve the controllability and flexibility of production.

Slaughter waste harmless treatment meat and bone meal production equipment is not only an effective tool to solve the problem of farming waste, but also a key technology to promote the green development of the farming industry. With the increasingly stringent environmental regulations, and the concept of green farming deeply rooted in people’s hearts, the future of this equipment will usher in a broader market prospects around the world. For farming enterprises, investment in harmless treatment of slaughter waste equipment, not only to enhance the production efficiency of the wise choice, but also to contribute to the cause of environmental protection of the responsibility to bear.

Through the slaughter waste harmless treatment of meat and bone meal production equipment, the farming industry will move towards a more environmentally friendly, green and efficient future.

Categories

Recent Posts

-

What is harmless treatment of sick and dead animals and poultry(rendering plant) A Key Initiative to Protect the Ecological Environment and Food Safety.

March 6, 2025 -

How does Sunrise rendering plant equipment destroy avian influenza viruses in livestock poultry carcasses

March 5, 2025 -

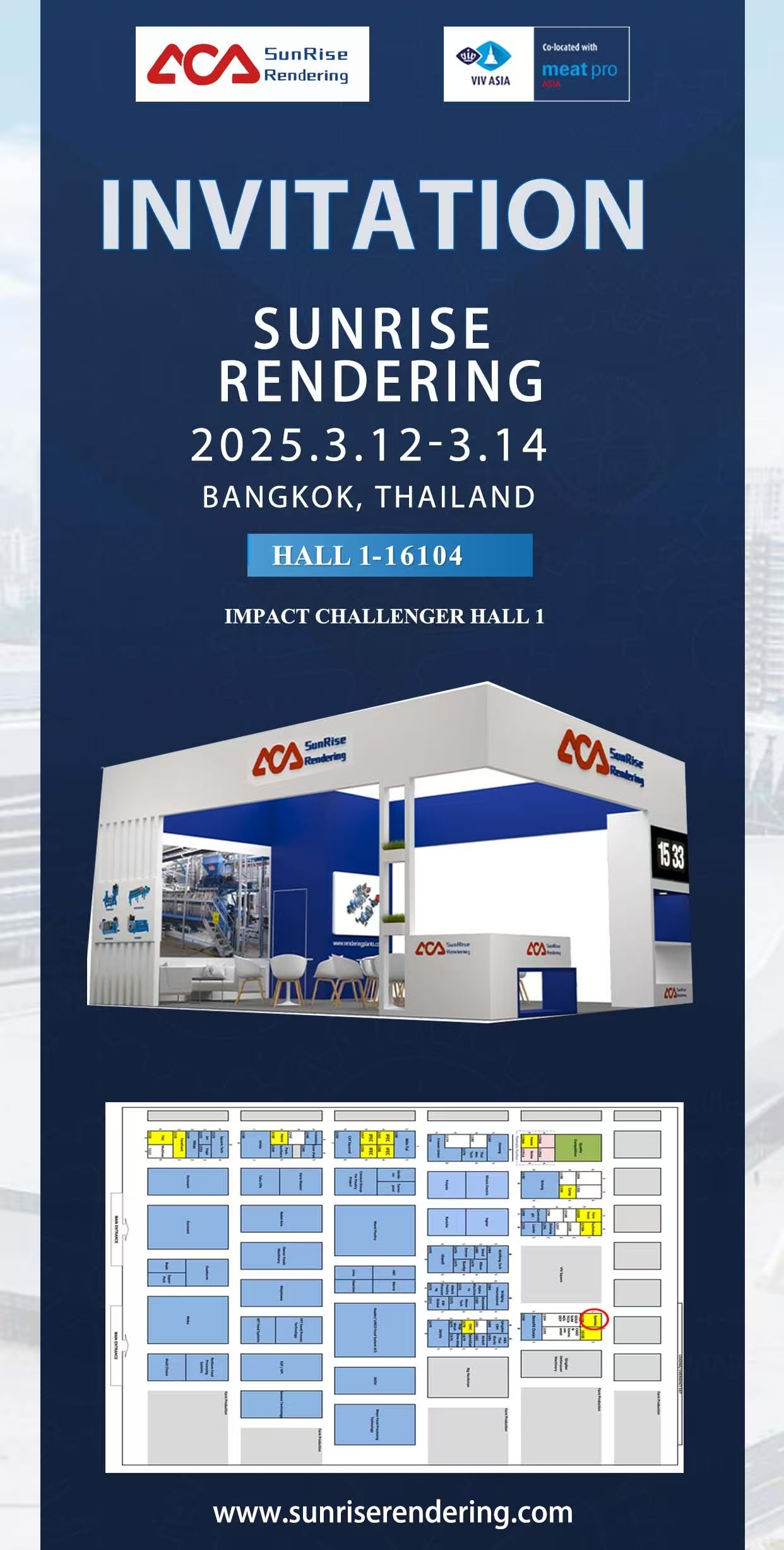

Sunrise Rendering Thailand Exhibition

March 5, 2025