Small Capacity Rendering Plant: Market Trends and Business Opportunities

Small Capacity Rendering Plant: Market Trends and Business Opportunities

The livestock and poultry industry relies heavily on small rendering plants for the processing of animal by-products, which are eventually transformed into highly valuable products, such as feed, fats, and proteins. In this article, we’re taking a closer look at the market trends and unexplored business opportunities available for owners of small capacity rendering plants. Keeping tabs on emerging markets, industry developments, and sustainability practices can help owners make informed decisions while also opening up pathways for expansion. To better understand these avenues for growth, we’ve invited Jiangsu SunRise Environmental Protection Technology Co. Ltd., an esteemed manufacturer in the rendering plant sector, to contribute their insights.

Emerging Markets and Demand for Rendered Products:

The global demand for rendered products, such as animal fat and protein meals, continues to grow steadily due to factors such as population growth, increasing per capita meat consumption, and expanding pet food markets. Small rendering plants can tap into emerging markets, particularly in many countries, where the demand for animal feed and protein-rich products is rising. By keeping an eye on these market trends, plant owners can identify opportunities to expand their operations and cater to the growing demand.

Benefits of Small Capacity Rendering Plants:

Small capacity rendering plants have distinct advantages over their larger counterparts. These plants offer flexibility in terms of location and operational scale. Their compact size allows them to establish operations in regions where land availability may be limited or where zoning restrictions make it challenging for larger facilities to operate. Additionally, small rendering plants can effectively utilize locally sourced raw materials, reducing transportation costs and promoting sustainability by minimizing the carbon footprint. Moreover, the proximity to their target markets allows for shorter delivery times and greater customer responsiveness.

Alternative Feed Sources and Resource Efficiency:

Small rendering plants can benefit from exploring alternative feed sources for their processes. With the rising focus on sustainability and environmental concerns, utilizing non-traditional inputs like poultry waste, fish waste, and other animals can be advantageous. By diversifying their feed sources, rendering plants can contribute to reducing waste and conserving resources, while also potentially accessing new markets and customers who value sustainable practices.

Resource-Efficient Equipment by Jiangsu SunRise:

Jiangsu SunRise Environmental Protection Technology Co. Ltd is a leading manufacturer of rendering plant machines, offering a comprehensive range of equipment designed to enhance resource efficiency and sustainability. Their equipment not only ensures efficient rendering processes but also supports the utilization of alternative feed sources. Let’s explore some of the key machines they offer:

Sustainability Trends and Value-Added Products:

Sustainability is a key trend in the rendering industry. Small capacity rendering plant owners can adapt to this trend by implementing energy-efficient practices, utilizing renewable energy sources, and minimizing the environmental impact of their operations. Additionally, there is a growing demand for value-added products derived from rendering processes, such as biodiesel and biogas. Plant owners can explore opportunities to integrate these value-added products into their business models, thereby creating additional revenue streams and enhancing their sustainability credentials.

Environmental Impact Mitigation: Waste Management and Emission Control

Addressing environmental concerns is crucial for small capacity rendering plants aiming for sustainability. Proper waste management practices, such as utilizing anaerobic digestion systems, can convert organic waste into valuable resources like biogas and organic fertilizers. Additionally, implementing effective emission control measures, such as scrubbers and filters, helps minimize air pollution and improve local air quality. By prioritizing waste management and emission control, small capacity rendering plants can contribute positively to the communities in which they operate.

Jiangsu SunRise Environmental Protection Technology Co. Ltd:

Jiangsu SunRise Environmental Protection Technology Co. Ltd is a prominent manufacturer specializing in rendering plant equipment. With their expertise in design, manufacturing, and installation, SunRise offers high-quality solutions tailored to small capacity rendering plants. Their equipment includes rendering cookers, screw presses, dryers, and odor control systems. SunRise is committed to providing reliable, efficient, and environmentally friendly rendering solutions to their customers worldwide, enabling plant owners to optimize their operations and meet industry standards.

A. Enhancing Efficiency with SunRise Rendering Equipment:

1. Rendering Cooker: The Heart of the Operation:

At the core of any rendering plant lies the rendering cooker, and SunRise excels in designing and manufacturing state-of-the-art batch cookers. These cookers ensure efficient and uniform cooking of raw materials, resulting in high-quality rendered products. With precise temperature control and optimized heat transfer, SunRise rendering cookers provide small capacity plants with the reliability and performance they need.

2. Screw Presses: Maximizing Fat Extraction:

Fat extraction is a critical process in rendering plants, and SunRise offers advanced fat screw presses to optimize this step. Their screw presses efficiently separate fat from solid materials, ensuring maximum fat recovery and minimizing waste. By integrating these presses into small capacity rendering plants, SunRise helps plant owners achieve higher yields, increased profitability, and reduced environmental impact.

3. Dryers: Rapid Moisture Removal:

To obtain superior quality rendered products, moisture removal is essential. SunRise dryers offer innovative solutions that accelerate the drying process, minimizing the time required while maintaining product integrity. With their cutting-edge technology, small capacity rendering plants can enhance their production efficiency and ensure consistent product quality.

B. Addressing Environmental Concerns:

1. Odor Control Systems: Eliminating Unpleasant Odors:

Odor control is a significant concern in rendering plants, as it affects both workers’ well-being and the surrounding environment. SunRise specializes in odor control systems that effectively capture and treat foul odors, preventing their release into the atmosphere. By implementing these systems, small capacity rendering plants can operate in compliance with environmental regulations while maintaining a clean and safe working environment.

2. Embracing Sustainability:

SunRise Environmental Protection Technology Co. Ltd recognizes the importance of sustainability in rendering operations. Their rendering plant equipment is designed with energy efficiency in mind, helping small capacity plants reduce their carbon footprint. By implementing SunRise equipment, plant owners can contribute to a greener future and enhance their reputation as environmentally responsible businesses.

C. Meeting Customer Needs:

SunRise Environmental Protection Technology Co. Ltd understands that each rendering plant has unique requirements. With their vast experience in the industry, they offer tailored solutions that address specific challenges faced by small capacity plants. Whether it’s selecting the right equipment, providing customized designs, or offering expert installation and support services, SunRise is dedicated to ensuring customer satisfaction throughout the entire rendering process.

Conclusion:

Small capacity rendering plant owners have ample opportunities to thrive in the evolving market landscape. By staying informed about emerging markets, demand for rendered products, alternative feed sources, and sustainability trends, owners can position themselves for growth and success. Additionally, partnering with reputable manufacturers like Jiangsu SunRise Environmental Protection Technology Co. Ltd can ensure access to high-quality equipment and expertise, enabling owners to enhance their operations and contribute to a sustainable future.

Categories

Recent Posts

-

What is harmless treatment of sick and dead animals and poultry(rendering plant) A Key Initiative to Protect the Ecological Environment and Food Safety.

March 6, 2025 -

How does Sunrise rendering plant equipment destroy avian influenza viruses in livestock poultry carcasses

March 5, 2025 -

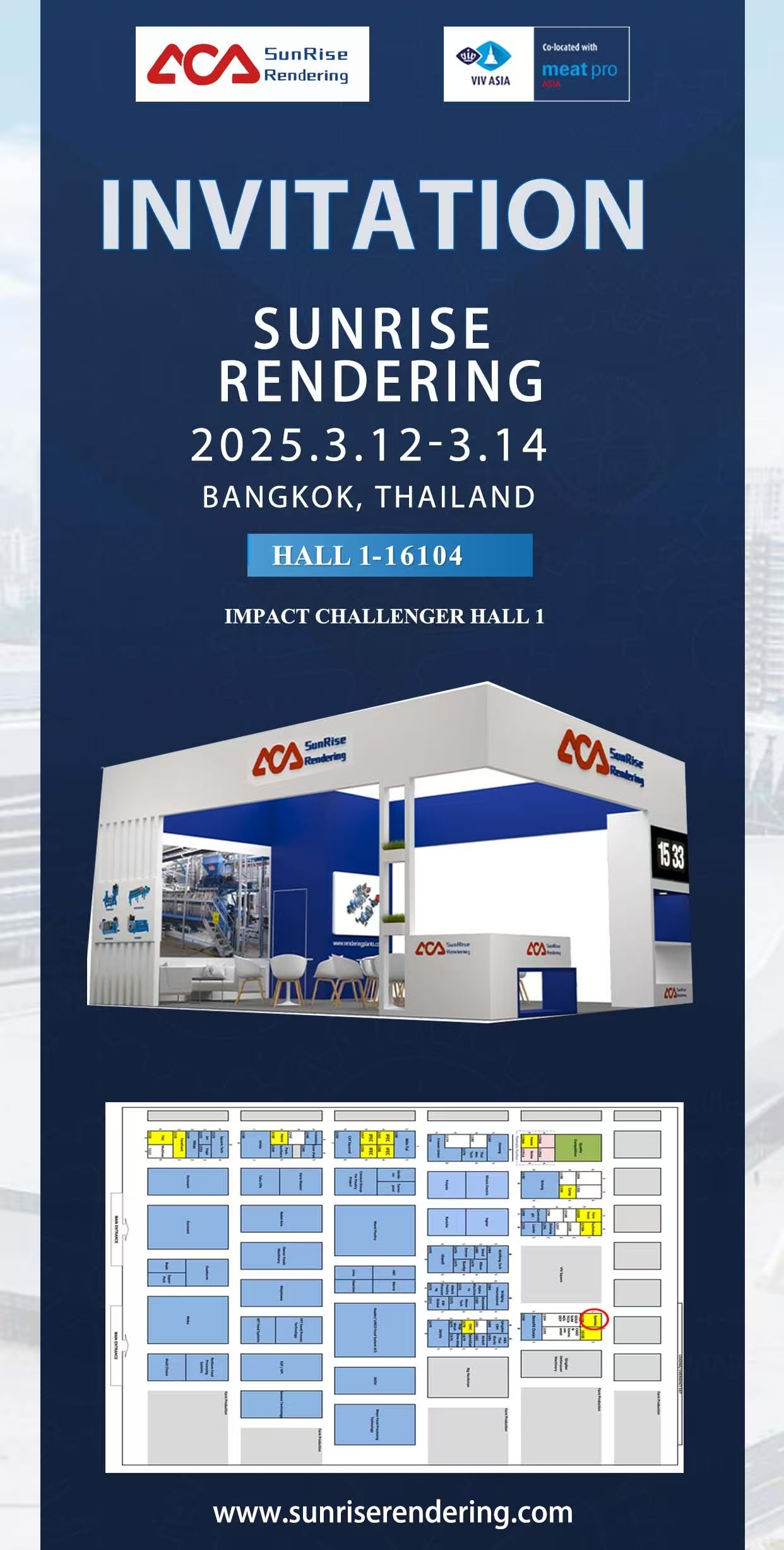

Sunrise Rendering Thailand Exhibition

March 5, 2025