The Nose Knows: Understanding the rendering plant smell

The Nose Knows: Understanding the rendering plant smell

What exactly is rendering plant smell for?

Factories play a significant role in our civilisation by processing animal byproducts and turning them into usable goods like animal feed, biodiesel, and fertilizers. However, these establishments frequently release potent, disagreeable odours that might spread to nearby neighbourhoods. Our most well-known business, SunRise, when it comes to emitting full, rendering plant smell emissions, is arguably the rendering sector. Depending on the procedures and raw materials, they can emit a wide range of distinct odours. It is imperative for operators to deploy efficient odour-control tools and procedures. You may avoid having an adverse effect on nearby populations, reduce smell complaints, and adhere to the conditions of your operating licenses by practising good odour control.

How can SunRise assist you?

- Working with operators of rendering factories is something we’ve done for many years. To verify rendering plant smell complaints and lessen odour emissions from your plants, we’ll work directly with you. You can find areas where you can improve by using the data and analyses, we have collected from our smell measurement. Providing the regulator with evidence that you have complied with your operating permissions would be helpful as well.

- Effective planning is essential for daily smell control to reduce your scent emissions properly. You will be able to recognize and address smell concerns before they worsen if you are proactive and routinely sample and test for odours. We can be certain of the correctness of our results and the promptness of the information because of our expertise and comprehension. We utilize the odour characterization as a very helpful technique to further determine the possible effects of scent on the general population.

- When olfactory conflict issues are brought before the court, doing so is also seen favourably. Our staff can assist you in creating your rendering plant smell management strategy since we have accreditation for odour sampling and odour testing. In addition, we may assist with planning new locations, procedures, or smell abatement technology.

- You may better comprehend the effects of your planned changes with the assistance of our design recommendations and dispersion modelling services. Then, you can make the necessary adjustments to your plans to make sure the best smell mitigation techniques are in place. Changes may be implemented considerably more quickly and affordably during the planning stage than after installation.

Odour control system

Technology for smell control must be very good, according to the rendering industry. Large emissions of foul odour are produced in this sector per tonne of processed material. Cooking, drying, and pressing are some of the many sources of scent in animal byproducts. Organic pollutants from vapours or heated air, such as oxide, sulphur, ammonia, and nitrogen, pollute the air. There are varying levels of contamination in each raw material. The air may generally be treated by:

- The polluted vapour condensing

- Vapour incineration

- Injection of direct water into the gas scrubbers

- Application of an indirect heat exchanger for vapour condensation

- Use of biofilters and chemical treatment

Witness the Beauty of Sunrise: A Solution to Rendering Plant Smell

The processing and disposal of animal byproducts are crucially dependent on rendering factories, yet these facilities frequently have a negative side effect: offensive odours. Residents and businesses in the area have long complained about the offensive smell coming from rendering operations. During the rendering process, noxious gases and chemicals are released, producing a unique and strong odour that may be detrimental to the quality of life in the neighbourhood. SunRise offers an efficient remedy for this offensive odour.

We are able to help our effort to monitor and reduce the impact of our factories’ odours not only by providing the necessary analysis but also by using our specialist expertise. Over the years, a number of management personnel have visited the location and returned with a thorough understanding of olfactometry and the best ways to manage smell. Our ability to track the effectiveness of our treatment systems (both treatment effectiveness and outlet conditions) is crucial to us. Knowing how well our treatment systems work enables us to create maintenance schedules, adjust setpoints to control the incoming load and distribute foul air across treatment systems in the appropriate manner.

Considerations for Choosing Rendering Factory Rendering Machines

Animal by-products, including fat, bone, and protein, are processed in animal rendering factories to create valuable goods like animal feed, fertilizer, and biofuels. Facilities produce these by-products for processing animals, such as slaughterhouses, meat packing houses, and poultry processing facilities. By guaranteeing that the by-products produced by animal processing facilities are not wasted but transformed into valuable goods, factories play a crucial role in the food business. Additionally, they contribute significantly to environmental sustainability by eliminating the landfill disposal of animal byproducts, which can cause environmental damage. You must select the appropriate equipment for your business to establish an animal rendering company.

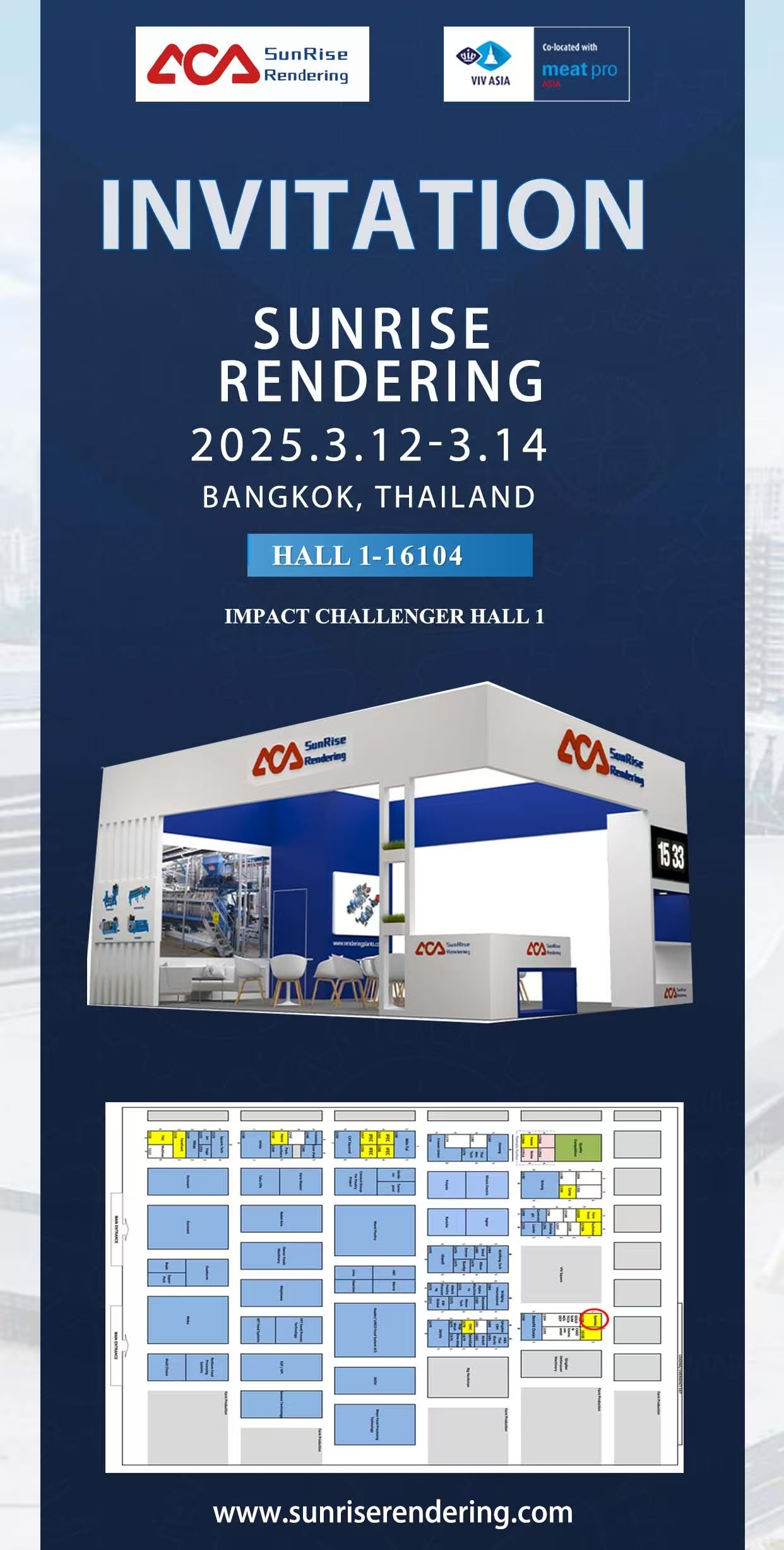

Sunrise Environmental Protection, a pioneering business in the rendering plant sector, showcased its cutting-edge animal protein conversion (rendering plant) technology and cutting-edge goods, setting the pace for the sector’s growth.

A variety of extremely effective and ecologically friendly animal protein conversion equipment (rendering plant equipment) and solutions were displayed at the exhibit, attracting the interest and admiration of experts and business representatives. With our superior product performance and top-notch customer service, Sunrise Environmental Protection has gained the trust of our clients and is established as a leader in the sector.

Conclusion:

Animal byproducts are disposed of and recycled in rendering factories, turning them into valuable goods like animal feed, biofuel, and fertilizer. For more than 30 years, SunRise has been specializing in developing and manufacturing equipment for rendering animal and bird waste and for protein conversion from abattoir waste. We are a leading producer of contemporary machinery with design, product production, installation, and training processes.

Categories

Recent Posts

-

What is harmless treatment of sick and dead animals and poultry(rendering plant) A Key Initiative to Protect the Ecological Environment and Food Safety.

March 6, 2025 -

How does Sunrise rendering plant equipment destroy avian influenza viruses in livestock poultry carcasses

March 5, 2025 -

Sunrise Rendering Thailand Exhibition

March 5, 2025