Waste Feather Processing Machine for Poultry Farming & Textile Manufacturing

Waste Feather Processing Machine for Poultry Farming & Textile Manufacturing

In the ever-evolving landscape of sustainable practices, industries such as poultry farming and textile manufacturing have been striving to find innovative solutions for waste management. One name that shines bright in this domain is SunRise, a pioneering waste feather processing machine wholesaler. This blog delves into the profound impact of waste feather processing machines on poultry farming and textile manufacturing, shedding light on the challenges and opportunities they bring to the table.

Waste Feather Processing Machines have been around for a while now, but these machines were not able to efficiently process the feathers into something that could be reused. However, SunRise recently developed a new technology that can transform feathers into reusable material in an efficient and environmentally friendly way.

Embracing the Waste Feather Processing Machine translates into a multitude of benefits from both an environmental and economic perspective. The reduction of feather waste in landfills alleviates pressure on these already overflowing sites. Moreover, by offering a viable alternative to conventional disposal methods, SunRise empowers businesses to align with sustainable practices, enhancing their green credentials and resonating with conscientious consumers.

Challenges in Waste Feather Management: An Eco-Conscious Call to Action

Feather waste has long posed a significant challenge for various industries, particularly poultry and textile. Traditional methods of disposal not only put a strain on landfill capacities but also fail to harness the potential value hidden within these discarded feathers. SunRise recognized this as an opportunity to innovate and contribute to sustainable waste management practices. Their Waste Feather Processing Machine is a testament to their commitment to environmental responsibility and resource maximization.

Poultry Farming: A Heap of Feathers

Poultry farming, a significant player in the agricultural sector, generates a substantial amount of waste feathers. Traditionally considered a byproduct with limited usability, feathers often find their way to landfills or incinerators, contributing to environmental degradation. This approach not only squanders a potential resource but also poses a significant challenge in terms of waste disposal.

SunRise: Illuminating the Path to Sustainability

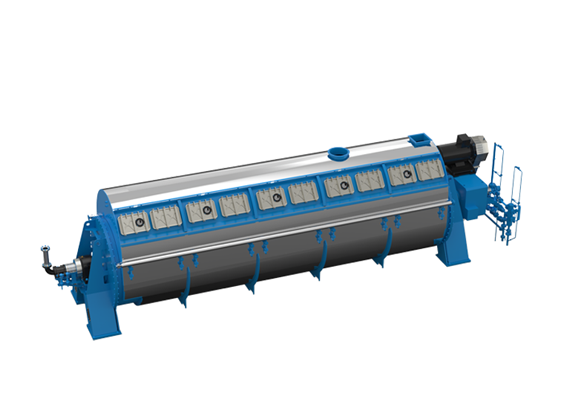

At the heart of this transformative solution lies the Waste Feather Processing Machine, a sophisticated apparatus designed to efficiently process and upcycle discarded feathers. This technology boasts a range of advanced features that set it apart in the waste management landscape. Equipped with state-of-the-art sorting mechanisms and sterilization processes, the machine ensures that feathers are thoroughly cleaned and sanitized, paving the way for various applications.

Poultry Farming Transformation

SunRise has emerged as a beacon of hope for poultry farmers seeking sustainable waste management solutions. Their waste feather processing machines are designed to efficiently clean, sterilize, and process feathers into high-quality materials. These materials can be used for a range of applications, from organic fertilizers to animal feed supplements, reducing waste and closing the loop in the poultry farming cycle.

Opportunities on the Horizon: Economic and Environmental Advantages

At the helm of this revolutionary technology is SunRise, a wholesaler dedicated to environmental progress and innovative solutions. With their Waste Feather Processing Machine, they have demonstrated their commitment to pushing the boundaries of waste management, driving positive change on a global scale. By providing industries with a tool to unlock the potential of waste feathers, SunRise is not only shaping a greener future but also encouraging a paradigm shift in how waste is perceived and managed.

3.1 Economic Growth through Innovation

By embracing waste feather processing machines, both poultry farmers and textile manufacturers can tap into new revenue streams. Poultry farmers can sell processed feathers as valuable byproducts, while textile manufacturers can create unique feather-blend products that cater to eco-conscious consumers. This innovation not only reduces waste management costs but also opens doors to potential collaborations and market expansion.

3.2 Environmental Prosperity: A Win-Win Situation

The adoption of waste feather processing machines holds remarkable environmental benefits. Reduced landfill waste and diminished incineration contribute to lower carbon emissions and alleviate pressure on landfills. Moreover, the repurposing of feathers conserves natural resources that would otherwise be consumed in the production of conventional materials. This virtuous cycle embodies the essence of sustainability. The journey towards a greener future starts with innovative solutions like those provided by SunRise, illuminating a path that industries can tread upon with confidence and hope.

Conclusion: A Feathery Future

The Waste Feather Processing Machine by SunRise stands as a beacon of innovation in the waste management arena. With its ability to transform discarded feathers into valuable resources for agriculture and textiles, this technology epitomizes the shift towards sustainable practices. As SunRise continues to lead the charge in waste management solutions, the future looks brighter—both for industries seeking eco-friendly alternatives and for a planet in dire need of innovative ways to manage its waste.