Waste rendering plants: Transforming Waste into Valuable Resources

Waste rendering plants: Transforming Waste into Valuable Resources

Introduction:

Rendering farm animal waste offers a win-win option for your company and the environment, whether you work at a fish farm or produce cattle, pigs, or chickens. Even though there are numerous options for getting rid of animal waste, they could be better at recycling and getting rid of it all at once. You will need the appropriate tools to do it, of course. The advantages of waste rendering plants and how to effectively recycle and reuse all kinds of animal by-products using SunRise unique corpse disposal solution for fish and other farm animals will be covered in more detail in the following article.

What is meant by waste rendering plants?

The maintenance of a sustainable ecosystem depends on effective waste management. Creating effective and environmentally friendly ways to deal with the garbage produced is essential because of the expanding population and rising consumption rates. Waste rendering plants are one such technique that has become quite important recently. These rendering factories are essential to manage and dispose of numerous waste kinds. These facilities are made to treat organic waste materials through several intricate procedures, including grease, food scraps, and animal by-products. These rendering plants are essential to manage and dispose of numerous waste kinds. These facilities are made to treat organic waste materials through several intricate procedures, including grease, food scraps, and animal by-products.

What advantages do waste rendering plants offer?

Another method of recycling farm animal waste and byproducts that are inappropriate for human consumption is waste rendering plants to recover lipids and proteins that may be used as fertiliser or animal feed. This is the perfect solution for agricultural workers to give their cattle high-quality nourishment without buying it from other sources. The blood, flesh, feather, and bone meal created as a consequence of rendering contains proteins and lipids crucial for the welfare of farm animals. In reality, rendered waste products may be the foundation for many other goods, including soaps, paints, candles, plastics, and rubber goods. Almost no chance of any bacterium or virus remaining present after the carcasses have been processed since all animal by-products are sterilized at extremely high temperatures.

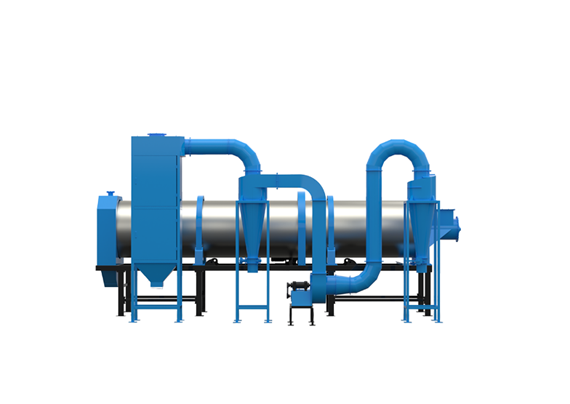

How does SunRise render technology for animal waste function?

- Our proprietary sterilization and shredding technology, used in hospitals and clinics worldwide, is the foundation of our farm animal rendering equipment. Our Facility can handle complete animal corpses, such as those from cattle, pigs, poultry, and even fish farms.

- The on-site Facility of SunRise can sterilise medical-grade materials using high-pressure, high-temperature steam between 121 and 134 degrees Celsius. Due to its low energy usage, it leaves a very minimal environmental imprint, which lowers your company’s operating expenses. Additionally, compared to other rendering systems, it consumes much less water.

- It also complies with the highest international quality requirements and produces no dangerous compounds or unpleasant odours.

- All farm animal corpses will be rendered by strong shredding blades, divided into solids and liquids, and mechanically dried to produce final products that may be used as organic fertilizer or animal feed.

It is a legal requirement for all farms and slaughterhouses to handle animal waste and carcass disposal. However, this does not imply that farm animal rendering cannot be profitable: The onsite equipment from SunRise lets you operate effectively by collecting beneficial byproducts that can be used again as organic fertilizer or animal feed in addition to offering an efficient and secure means to dispose of animal waste.

Streamlining the Supply Chain:

SunRise Environmental’s fish meal processing equipment is made to optimize every step of the manufacturing process, from handling raw materials to produce the finished product. These devices greatly save manual labour, shorten processing times, and increase overall effectiveness by automating several phases, including heating, pressing, drying, and cooling. This organized process boosts output and guarantees consistent product quality, satisfying market needs.

- Increased Productivity Resulting from Automation

The capacity to automate different steps of the production process is one of the main benefits of SunRise Environmental’s fish meal machines. Our machines are excellent at handling raw materials, cooking, pressing, drying, and cooling, among other activities. These labour-intensive processes are automated by machines, greatly reducing the demand for physical labour. This enhances Productivity while simultaneously lowering production costs. The automated procedures guarantee a dependable and effective workflow, enabling the production of greater amounts of fish meals in less time.

- Consistently High-End Products

In the fish meal sector, maintaining consistent product quality is crucial. The fish meal processing equipment from SunRise Environmental is built to guarantee that every batch of fish meal satisfies the highest requirements. The devices provide cooking, pressing, drying, and chilling consistency by automating crucial production phases. This uniformity removes the possibility of product quality deviations, giving clients a dependable and excellent finished good. All parameters, including temperature and moisture levels, are maintained at ideal levels throughout the process thanks to the machines’ precise control mechanisms and monitoring systems.

Fish meal manufacturing requires quick processing, and SunRise Environmental’s equipment is excellent. By automating various steps, these devices greatly shorten the manufacturing time needed to convert raw fish into premium fish meals. The simplified process ensures that each phase flows into the next without interruption, reducing downtime and removing bottlenecks. The machines’ effective heat recovery and energy consumption systems also increase efficiency. These qualities adhere to sustainable manufacturing fundamentals while lowering operational expenses.

- Logistics and Distribution:

Fish meal machine manufacturers, like SunRise Environmental, know the value of logistics and distribution in effectively delivering their goods to clients. Distributors participating in the supply chain for fish meal machines can learn about equipment procurement, shipping, warehousing, import/export laws, and network management from supply chain and logistics blogs. Distributors may streamline business processes, cut costs, and improve customer satisfaction by keeping up with industry developments and best practices.

Conclusion:

Waste rendering plants have gained popularity as a potential remedy for the escalating environmental issue in recent years. These establishments, often called trash treatment or recycling factories, are experts at turning organic waste into useful goods or energy sources. Dedicated to animal protein, oil, nutrition, food, biotechnology, and solid waste treatment, SunRise is a complete environmental protection technology limited business. Our firm has introduced and adopted effective management practices, project processing technologies, and equipment production technologies throughout Europe for a century.