rendering plant equipment on farms

What are the standards for the facility requirements for rendering plant equipment on farms?

Farm harmless treatment equipment facilities are not only the basic requirements of environmental protection, but also the necessary conditions for the sustainable development of modern farming. This article explains in detail the standards and requirements of farm harmless treatment equipment and facilities to help farmers to improve the level of facility construction, to protect the environment and public health.

With the rapid development of the modern farming industry, the scale of farms is expanding, and the problem of the treatment of farming waste is becoming increasingly serious. In order to cope with the large amount of waste produced in the process of farming, the construction of harmless treatment equipment and facilities for farms is particularly important. Harmless treatment equipment can not only effectively reduce the pollution of farming waste to the environment, but also protect public health and ecological sustainability. What are the standards and requirements for the construction of environmentally sound treatment equipment on farms?

First, the necessity of harmless treatment equipment and facilities

The harmless treatment of farm waste mainly refers to the livestock and poultry carcasses, manure, feed residues and other wastes produced in the process of farming, so that they do not pollute the environment and do not affect the quality of life of the surrounding residents through scientific treatment. Therefore, harmless treatment equipment and facilities have become an indispensable part of modern farms.

At present, China’s farming industry has increasingly high requirements for waste treatment, which has prompted the continuous updating and upgrading of relevant equipment and facilities. According to the relevant environmental standards, farms must be equipped with efficient and environmentally friendly environmentally friendly treatment equipment to ensure the effective disposal of waste.

Sunrise Environmental Equipment Co., Ltd. specializes in manufacturing, efficient and durable livestock and poultry non-hazardous equipment.

Second, the functional requirements of harmless treatment equipment

High efficiency: The non-hazardous treatment equipment should first of all have high efficient processing capacity, and be able to quickly transform the breeding waste into harmless substances. For example, livestock and poultry carcasses, after physical crushing, high temperature and high pressure -, physical pressure and other procedures to ensure that the final waste meets the environmental requirements.

Environmental protection: the design of the harmless treatment equipment must meet the environmental requirements, in the treatment process should not produce secondary pollution. The equipment should have the function of deodorizing and reducing the emission of harmful gases, so as to avoid the influence of malodorous gases on the surrounding environment in the process of waste treatment.

Automation and Intelligent: Modern farms have higher and higher demand for automation and intelligence of equipment. Automation equipment can greatly reduce the burden of manual operation and improve work efficiency. Intelligent equipment can analyze and adjust the data of the waste treatment process through real-time monitoring system to ensure the treatment effect and stable operation of the equipment.

Economy: farms in the selection of environmentally friendly treatment equipment, but also take into account the investment cost of the equipment and the cost of operation and maintenance in the later stage. The equipment must have a long service life, and easy maintenance, can reduce operating costs.

Sunrise Environmental Equipment Co., Ltd. specializes in manufacturing, efficient and durable livestock and poultry non-hazardous equipment.

Third, the construction standards of harmless treatment equipment and facilities

According to China’s relevant regulations and environmental protection requirements, the farm harmless treatment equipment facilities must follow the following construction standards:

Environmental protection standards: harmless treatment equipment must meet national environmental standards to ensure that the treated waste will not cause pollution to the environment. Especially in terms of wastewater and exhaust emissions, the equipment needs to comply with the relevant provisions of the Technical Specification for Comprehensive Utilization and Harmless Treatment of Agricultural Waste.

Disinfection requirements: The equipment should have strict disinfection function to ensure that the waste does not carry pathogenic bacteria, viruses and other harmful substances during the treatment process. Common disinfection methods include high temperature disinfection, ultraviolet ray disinfection and chemical disinfection.

Safety requirements: The equipment should comply with national safety standards to ensure that no leakage, fire, explosion or other safety accidents occur during operation. The equipment should have a perfect emergency response mechanism, so that once an abnormal situation occurs, measures can be taken quickly to deal with it.

Energy saving and emission reduction requirements: the harmless treatment equipment of the farm should have high energy utilization efficiency, and take measures to reduce energy consumption and greenhouse gas emissions. The use of energy-saving equipment can effectively reduce the operating costs of the farm and minimize energy waste.

Sunrise Environmental Equipment Co., Ltd. specializes in manufacturing, efficient and durable livestock and poultry non-hazardous equipment.

IV. Common types of non-hazardous equipment

Farms choose different types of non-hazardous equipment according to different needs and sizes. Common equipment includes:

Manure treatment equipment: including manure separators, anaerobic fermentation tanks, dewatering machines and so on. These equipments can treat, disinfect and convert manure into organic fertilizer.

Wastewater treatment equipment: through biological treatment, physical filtration and other means, remove pollutants in farm wastewater to ensure that wastewater discharge meets environmental standards.

Waste gas treatment equipment: mainly includes waste gas purification device and odor treatment equipment, which is used to eliminate the malodorous gases generated in the breeding process and prevent the impact on the surrounding environment.

Garbage treatment equipment: In addition to manure and wastewater, the farm will also produce a large number of feed residues and other solid wastes. Garbage treatment equipment is used to treat them through compression, sorting, incineration and other methods.

Sunrise Environmental Equipment Co., Ltd. specializes in manufacturing, efficient and durable livestock and poultry non-hazardous equipment.

V. Operation and management of environmentally sound treatment facilities

The operation and management of environmentally sound treatment equipment is crucial. Farms should regularly check and maintain the equipment to ensure that it is always in good working condition. Detailed records of the waste treatment process should be kept for inspection by the regulatory authorities. Through reasonable management and maintenance, farms can improve the service life of equipment and reduce the failure rate.

VI. Difficulties in the construction of environmentally sound treatment equipment and facilities

Although environmentally sound treatment equipment and facilities are crucial for farms, they still face some challenges during the actual construction process. The following are a few difficulties that farms often encounter when building environmentally sound treatment facilities:

Large capital investment: The investment in environmentally sound treatment equipment is usually large, especially for some small-scale farms, the financial pressure is large. Although the national and local governments have introduced a series of subsidy policies, for some farmers, there is still a shortage of funds.

High technical requirements: the selection and installation of environmentally sound treatment equipment is demanding and involves complex technical content. Some farmers lack sufficient technical personnel, resulting in difficulties in equipment selection and maintenance.

Poor adaptability of equipment: Farms of different sizes and types have different waste treatment needs. If the treatment capacity of the equipment does not match the actual situation of the farm, it may lead to poor treatment results or even secondary pollution.

High operating costs: farms may be smoother in the initial stage of equipment construction, but electricity, labor costs and maintenance costs in long-term operation should not be ignored. The high operating cost will bring economic pressure to the farm and affect its sustainable development.

Sunrise Environmental Equipment Co., Ltd. specializes in manufacturing, efficient and durable livestock and poultry non-hazardous equipment.

VII. How to solve these difficulties?

In order to solve the difficulties mentioned above, farms can improve in the following aspects:

Policy support: Governments at all levels should increase policy support for the construction of non-hazardous treatment facilities on farms, and reduce the economic pressure on farms by providing financial subsidies and preferential loans. Demonstration projects for the construction of environmental protection facilities should be actively promoted to enhance the environmental awareness of farms.

Strengthen technical training: farms should strengthen technical training for employees to improve their ability to operate and maintain equipment. Professional technicians can be hired or cooperate with equipment suppliers to jointly solve technical problems in equipment operation.

Precise equipment selection: When choosing harmless treatment equipment, farms must select the type scientifically according to the actual situation and demand. Equipment suppliers should provide customized solutions according to the farm’s scale, waste type and treatment volume.

Enhance the management level: farms should establish a perfect equipment management and maintenance mechanism, regularly check and maintain the equipment to ensure long-term stable operation and reduce the failure rate. Detailed waste treatment processes should be developed to ensure that the treatment process is standardized and orderly.

Sunrise Environmental Equipment Co., Ltd. specializes in manufacturing, efficient and durable livestock and poultry non-hazardous equipment.

VIII. Summary

The construction standards and requirements of farm harmless treatment equipment and facilities are not only related to environmental protection, but also directly affect the sustainable development of farms. In the construction and operation of these facilities, farmers need to combine the actual situation, scientific selection of equipment, standardized management, and solve the difficulties that may be encountered. By improving treatment efficiency and reducing environmental risks, they can not only improve the economic benefits of farms, but also contribute to environmental protection and promote the healthy development of modern farming.

Categories

Recent Posts

-

What is harmless treatment of sick and dead animals and poultry(rendering plant) A Key Initiative to Protect the Ecological Environment and Food Safety.

March 6, 2025 -

How does Sunrise rendering plant equipment destroy avian influenza viruses in livestock poultry carcasses

March 5, 2025 -

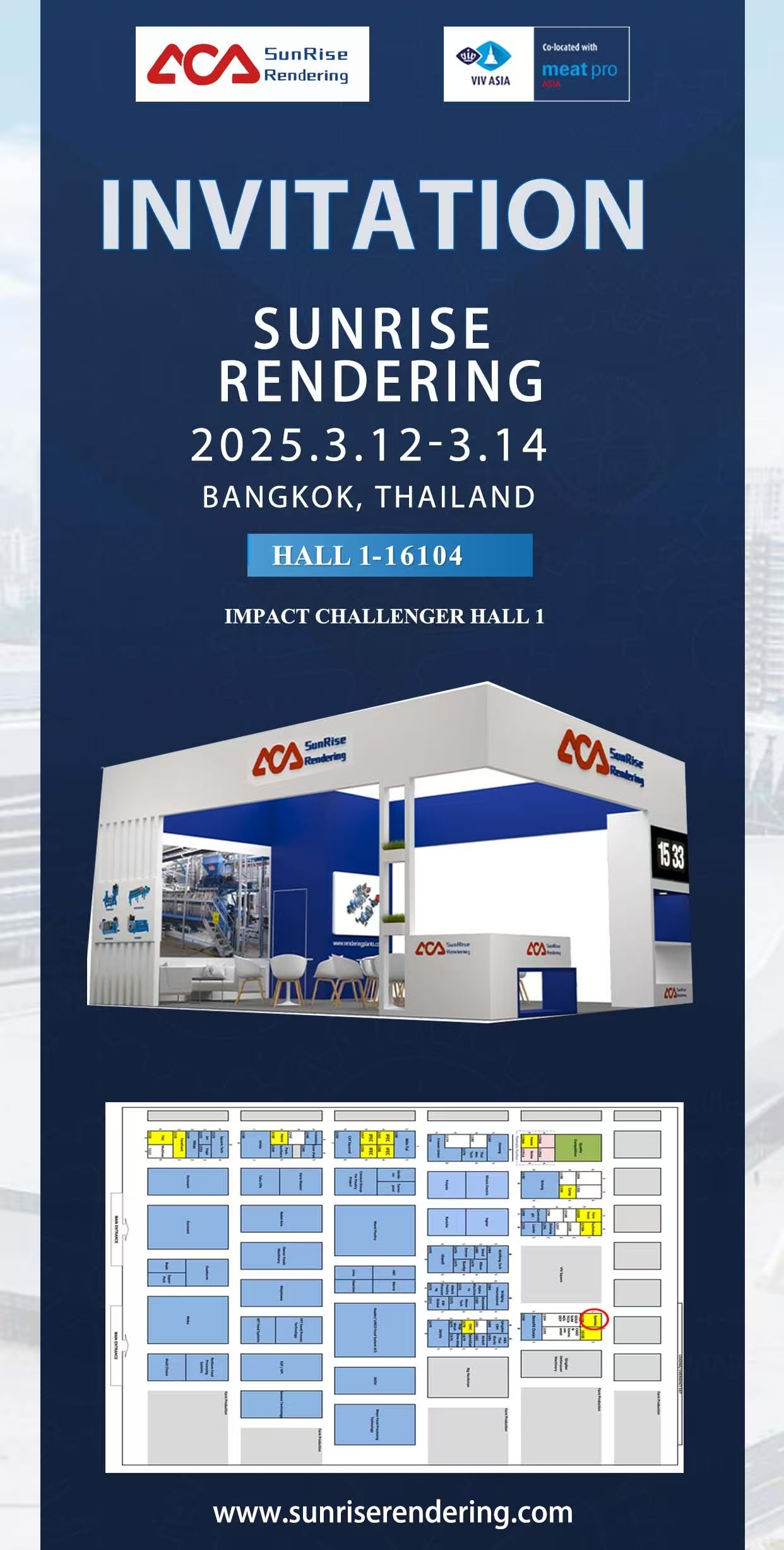

Sunrise Rendering Thailand Exhibition

March 5, 2025