Where To Buy A Disc Dryer?

Where To Buy A Disc Dryer?

What Are Disc Dryers?

Before you choose where to buy disc dryer, you should understand what a disc dryer is. In a rendering plant, disc dryers are used to remove moisture from meat and bone meal. In the rendering process, meat and bone are dried out so that they can be ground into a powder. The high temperatures that are used to dry out the material kill bacteria and other pathogens that might be present in the waste material.

Once the meat has been dried out, it is ground into a fine powder and then mixed with other ingredients to create the final product.

The disc dryer is an important piece of equipment for any rendering plant because it ensures that all of the moisture is removed before grinding begins. It helps prevent contamination of other products when they are produced.

What Are the Types of Disc Dryers?

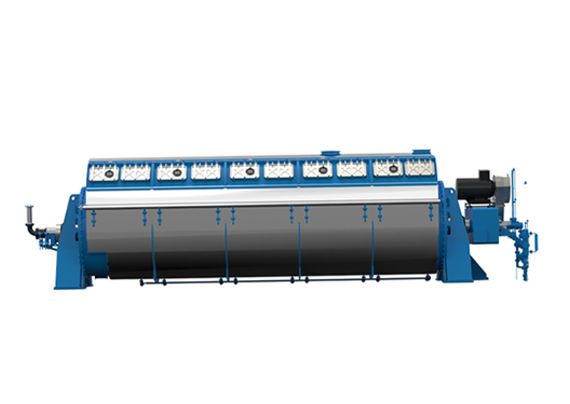

Before you choose where to buy disc dryer, you should also know the type of disc dryer. You can buy disc dryers from a manufacturer like Sunrise, Sunrise Disc Dryers with indirect steam heating are used to dry wet animal by-products and other materials. There are different types of disc dryers, some are:

Belt Driven Disc Dryer

A belt-driven disc dryer is the most common type of disc dryer. This is because it is easy to maintain, and can handle a wide range of materials. The belt drive system features a motor that drives a steel or rubber belt that moves the discs around on their shafts. The discs are mounted on arms that swing back and forth over the drying chamber.

Material to be dried is fed into the chamber by gravity at one end, while air heated by combustion gases passes through the chamber at the other end. As it passes over each disc, it removes moisture from the material being dried. This type of disc dryer is used mainly for drying sludge, waste materials, and other water-soluble substances.

Chain Driven Disc Dryer

A chain-driven disc dryer has two discs mounted on either side of a chain drive shaft. The shaft is supported by bearings at each end of its rotation axis, allowing it to spin freely without any resistance from friction or other forces acting against it.

The discs themselves are made up of many small blades mounted on arms that pivot around the center axis of each disc’s rotation point (known as its hub). As the blades spin around this hub, they push air downwards over the surface of each disc, separating any moisture present in the material being dried by removing it through evaporation and condensation processes within this airflow current produced.

Water Cooled Disc Dryer

Water-cooled disc dryers are designed to remove moisture from the fine aggregate by utilizing a combination of air and water. It is used to cool the discs after they have been heated by the hot compressed air. This process results in less wear and tear on the discs, and also reduces downtime due to maintenance.

This type of disc dryer is the most common and widely used to dry out all kinds of animal fats, tallows, and other products containing fat. The main function of the water-cooled disc dryer is to heat the fat or tallow, which will evaporate the moisture content in it.

Once the moisture content has been evaporated, the remaining solid material will become harder and more compact. The advantage of using this type of disc dryer is that it can be used to dry out different types of materials at high temperatures and low temperatures as well.

Hydraulic Driven Disc Dryer

A hydraulic-driven disc dryer uses a belt-driven piston pump to force water through discs that have been sprayed with oil so that they don’t become too hot while they’re drying out the animal fat. The oil helps keep them cool enough so that they don’t crack or warp under pressure.

Hydraulic-driven disc dryers are generally more expensive than other types of disc drier because of their high-tech design and construction materials, but they can also be more efficient at producing meat meal from animal byproducts because they maintain a constant temperature throughout the drying process without overheating any part of the machine.

Why Buy Disc Dryers From A Manufacturer?

Where to buy disc dryer, the best place to buy your disc dryer is from a manufacturer in a rendering plant. This is because the manufacturer can custom-build a disc dryer for you that will meet your exact needs. They will also be able to incorporate any special features that you might want into their design of the machine. If you buy from a manufacturer, they will also be able to provide maintenance and repair services for their machines after they have been installed by you.

There are many different types of disc dryers, but one type that you should consider purchasing is a disc dryer that comes from a manufacturer like Sunrise. They have been providing high-quality equipment for years, so you can trust that their products are reliable and will work well in your business.

One reason why you should buy your disc dryer from a manufacturer like Sunrise is that they have been around for a long time and have gained much experience with this type of product. They know what works best, so when they make their products they know exactly what to include. This means that when you purchase one of their products they will give you everything that you need to make sure that it works properly and efficiently every time you use it.

Another reason why it may be beneficial for you to buy your disc dryer from a manufacturer like Sunrise. When buying equipment directly from the manufacturer, oftentimes they will offer discounts or special pricing on their products as an incentive for customers to purchase directly from them.

This is because they do not have to pay any additional costs for middlemen or distributors to sell their products. They also sell directly to the customer which helps eliminate costs associated with shipping and handling products from one location to another.

How to Choose the Right Manufacturer?

There are many things that you need to consider where to buy disc dryer. While it is tempting to choose a company based on price or brand name alone, this can be a poor decision because these factors don’t always correlate with quality. Here are some tips on how to choose an excellent disc-drying machine manufacturer:

Look at Their Portfolio of Products

The best way to know if they are good at building disc drying machines is by looking at their portfolio of products. If they haven’t built any portfolio of products before or if they don’t have any customers who can speak on their behalf, then it may be better to go with someone else. In addition, if they don’t have any references available, then they might not be trustworthy enough for your business needs.

Check Their Reputation

Another way of seeing whether or not a particular manufacturer is worth your money is by checking its reputation online. You can do this by searching for them on social media sites like

Things to Consider when Buying Disc Dryers from a Manufacturer

There are many things to consider where to buy disc dryer from a manufacturer.

1. Size and Capacity

The size of the disc dryer should be determined by the amount of material you will be handling, as well as its moisture content, which is usually provided by the manufacturer. The capacity should also be considered because it determines how long it will take for a batch to dry.

2. Material

You should select a disc dryer that is constructed from durable materials like stainless steel or aluminum. This is because these materials are resistant to corrosion and have excellent heat transfer properties, which means they can quickly remove moisture from your product without causing physical damage or discoloration.

3. Quality Control System

You should make sure that your manufacturer has an efficient quality control system in place before you buy any equipment from them. This will ensure that all products meet government standards and are safe for use in food production plants

Conclusion

You can buy a disc dryer from any number of retailers and wholesalers. However, when you buy from Sunrise, you get more than just the product, you get their expertise, commitment to quality, and dedication to customer service.

Sunrise has been manufacturing disc dryers for over 30 years and we’ve learned a thing or two in that time. They know how to design a product that will last and perform flawlessly with minimal maintenance.

Their disc dryers are manufactured with only the highest quality components available, so these disc dryers will last longer than similar competing products. And because they are an established manufacturer with a large product line, they can offer you more options than most other companies can offer their customers – including custom configurations.